Perovskite quantum dot scintillation microcrystalline glass and preparation method thereof

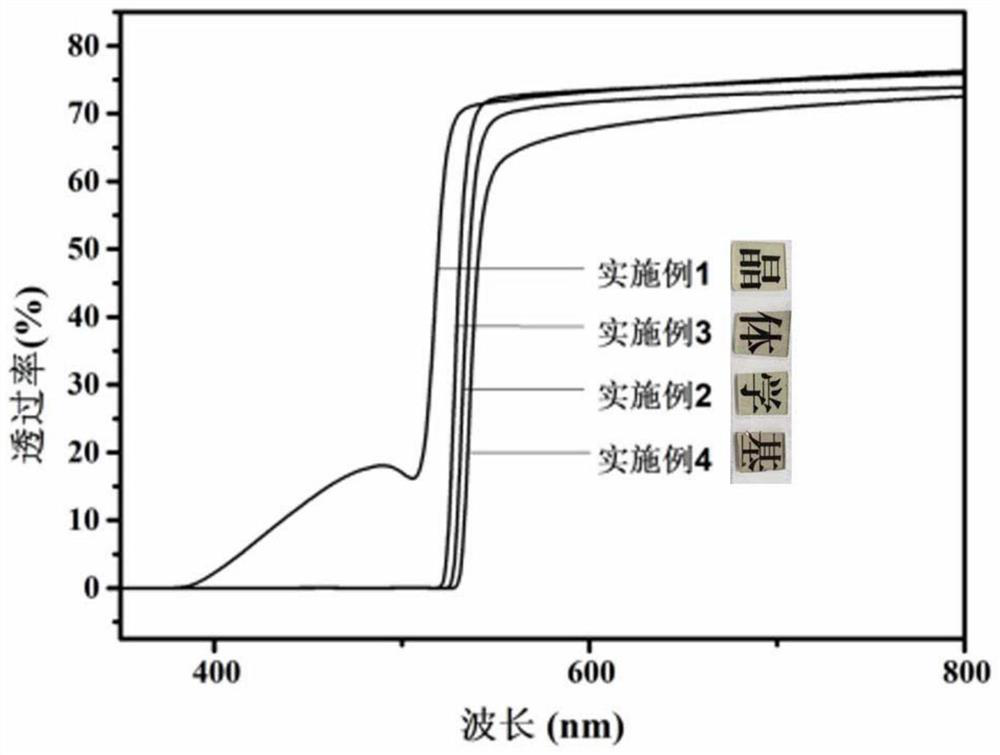

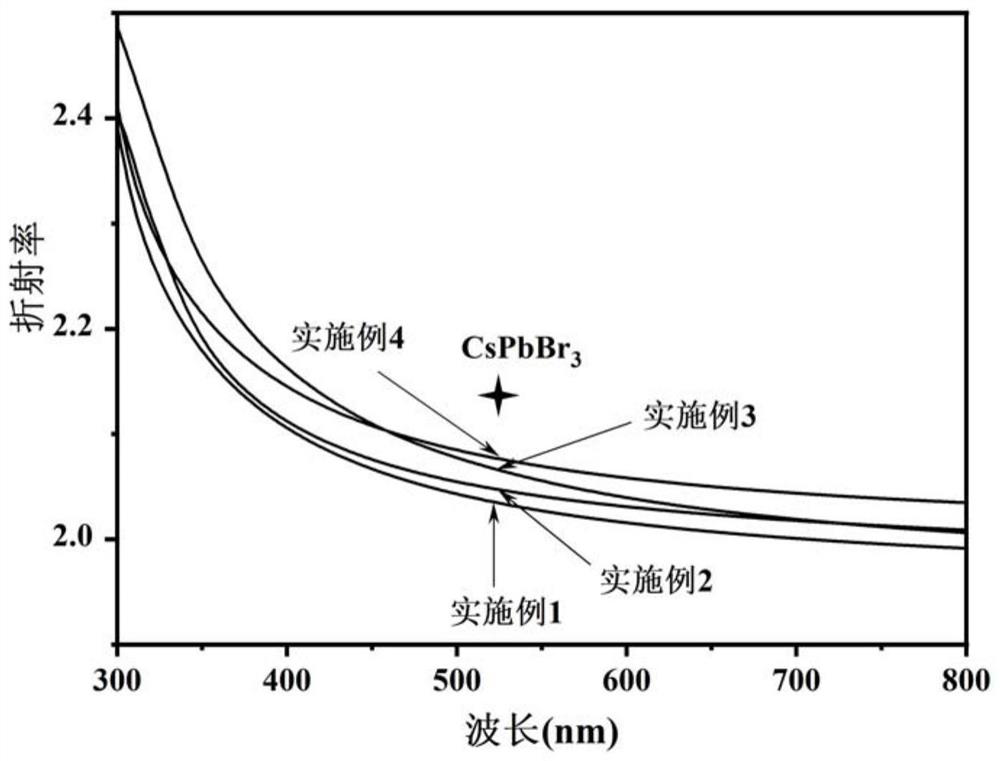

A technology of glass-ceramics and quantum dots, which is applied in glass manufacturing equipment, glass dosimeters, and glass molding. It can solve the problems of scintillator luminous intensity decline, nanocrystal damage, and high melting temperature, and achieve good X/γ Effects of ray cut-off capability, high glass density and refractive index, and low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the above-mentioned perovskite quantum dot scintillation glass-ceramic comprises the following steps:

[0050] S1: Accurately weigh each raw material according to the components of the scintillation glass, fully grind and mix uniformly to obtain a glass batch;

[0051] S2: Melting: in a heat-resistant container with a cover, melt the glass batch obtained in step S1 into a uniform melt, the melting temperature required according to the glass components is 700-1000 ° C, and the melting time is 0.1-0.5h , the melting atmosphere is air;

[0052] S3: Molding and annealing: the molten glass obtained in step S2 is properly cooled and released from the furnace, poured onto a mold to be quenched into block glass, annealed at a constant temperature to eliminate the internal stress of the glass, wherein the annealing temperature is 200-350°C, and the holding time It takes 1-4 hours to cool down to room temperature with the furnace to obtain the precursor...

Embodiment

[0062] The present invention will be described in more detail below in conjunction with the examples. Unless otherwise specified, the raw materials and equipment used in the examples can be purchased through commercial channels and operated under the guidance of the instructions.

[0063] 1. Preparation process

[0064] The preparation method of the above-mentioned luminescent glass comprises the steps of:

[0065] (1) Accurately weigh the raw materials according to the composition of the above-mentioned luminescent glass, and thoroughly grind and mix these raw materials to obtain a glass batch;

[0066] (2) Transfer the glass batch material to an alumina crucible and cover it, then melt, shape, anneal, and cool in an air atmosphere to obtain a precursor glass, and then heat-treat to obtain a perovskite luminescent glass-ceramic, Among them, the melting temperature is 850°C, the heating rate is 10°C / min to the melting temperature, the temperature is lowered to 750°C, and then...

Embodiment 2

[0082] The relative luminous intensity of the scintillation glass prepared in Example 2 under the excitation of X-rays of different powers, as shown in the attached Figure 8 shown. As the X-ray power increases, the radioluminescence intensity increases linearly. It can be used as an X-ray dosimeter to monitor X-ray signals in real time.

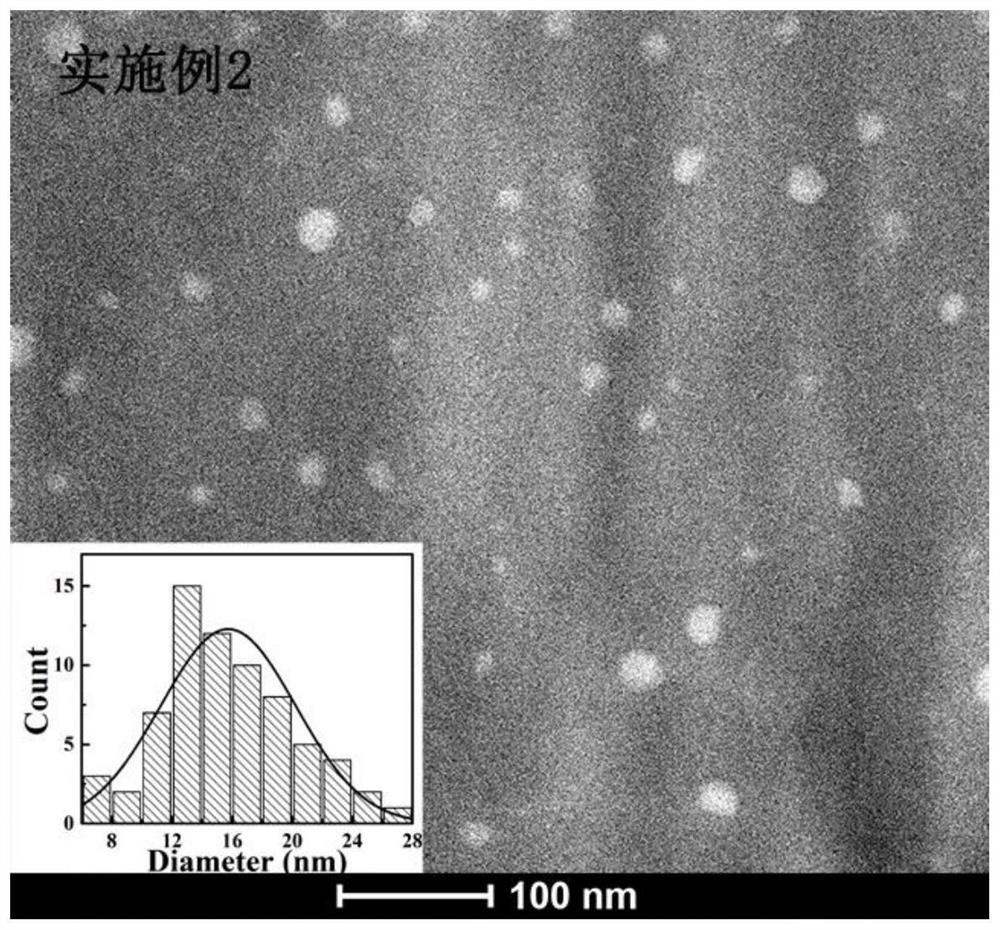

[0083] The emission spectra of the glass prepared in Example 2 under initial and continuous X-ray irradiation, as attached Figure 9 shown. Doped CsPbBr in prior art 3 The borate glass of quantum dots will cause crystal damage after X-ray irradiation, and dark spots will appear on the glass surface to affect its radioluminescence. However, the spectrum of the glass prepared above remains unchanged after X-ray irradiation for 10 minutes, proving that Scintillating glass has excellent radiation resistance.

[0084] The relative luminous intensity of the scintillation glass prepared in Example 2 under X-ray excitation after the heating-coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com