Method for modifying low electric field refrigeration performance of polyvinylidene fluoride ferroelectric polymer and its application

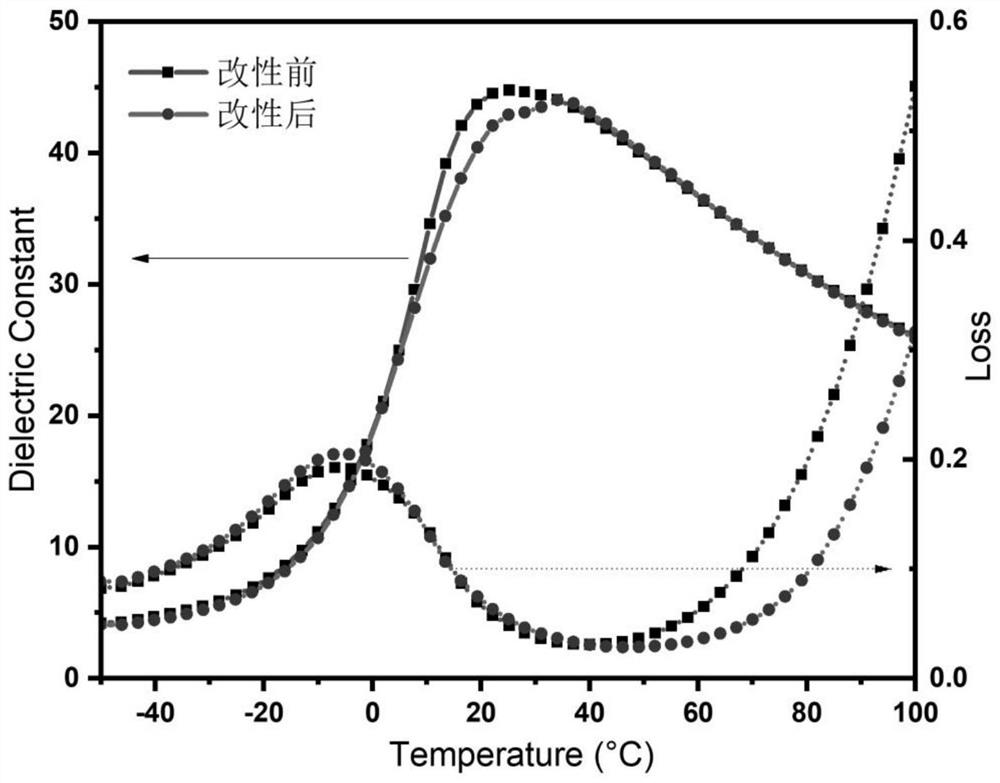

A technology of polyvinylidene fluoride and ferroelectric polymers, which is applied in the field of all-solid refrigeration, can solve the problems of lengthy reaction steps and complex electric card effect treatment process, reduce grain size, improve crystallization and electrical properties, reduce The effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

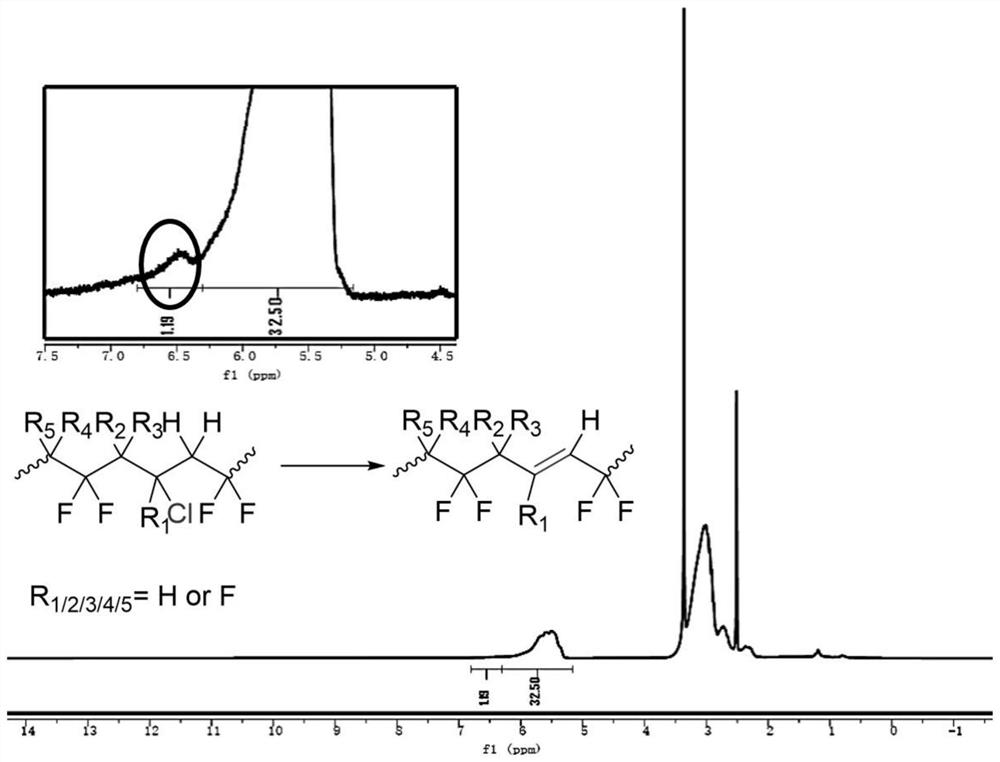

[0032] Preparation of Modified Polyvinylidene Fluoride-Vinyl Chlorofluoride Binary Copolymer

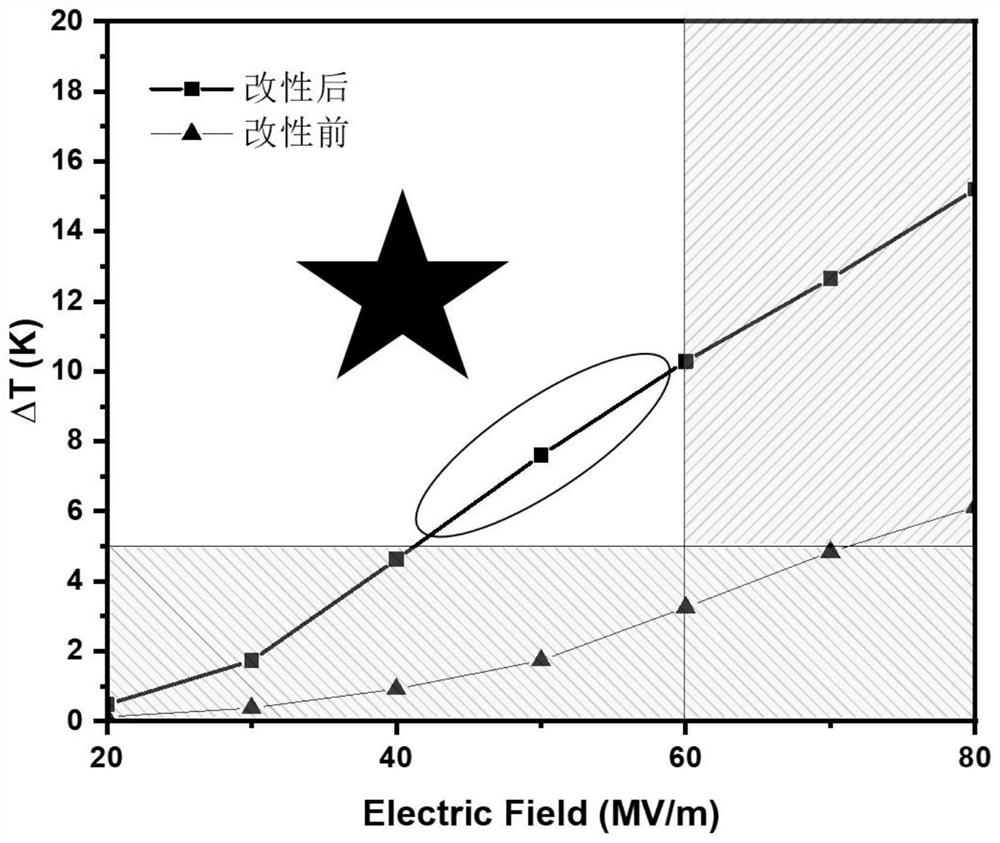

[0033] This embodiment includes the following steps: taking a double-necked round-bottomed flask, treating it with water and oxygen, weighing 1 g of polyvinylidene fluoride-chlorofluoroethylene P(VDF-CFE) (60 / 40mol%) binary copolymer, replacing gas for 3 times, and acetone solvent was added under nitrogen protection to fully dissolve the polymer at room temperature; 4.0 mL of hexamethylenetetramine was added dropwise to the reaction system, and the temperature was slowly raised to 40 °C, and the reaction was stirred for 2 h; after the reaction was completed , the reaction system was slowly cooled to room temperature, dropped dropwise into a mixed solution of ethanol and water with a volume ratio of 1:1, and the modified multi-component copolymer was obtained by precipitation; VDF-CFE) ferroelectric polymer. The test shows that 4.1K temperature change can be generated under the chang...

Embodiment 2

[0035] Preparation of Modified Polyvinylidene Fluoride-Chlorodifluoride Binary Copolymer

[0036] This embodiment includes the following steps: taking a double-necked round-bottomed flask, treating it with water and oxygen, weighing 1 g of polyvinylidene fluoride-chlorofluoroethylene P(VDF-CDFE) (66 / 34 mol%) binary copolymer, replacing Gas 3 times, N-methylpyrrolidone (NMP) solvent was added under nitrogen protection, and the polymer was fully dissolved at room temperature; 3.5 mL of diethylamine was added dropwise to the reaction system, and the temperature was slowly raised to 60 ° C, and the reaction was stirred for 45 min After the reaction, the reaction system was slowly cooled to room temperature, dropped dropwise into a mixed solution of ethanol and water with a volume ratio of 1.5:1, and the modified multi-component copolymer was obtained by precipitation; P(VDF-CDFE) ferroelectric polymer. The test shows that 6.3K temperature change can be generated under the change ...

Embodiment 3

[0038] Preparation of Modified Polyvinylidene Fluoride-Chlorotrifluoroethylene Binary Copolymer

[0039] This embodiment includes the following steps: taking a double-necked round-bottomed flask, treating it with water and oxygen, weighing 1 g of polyvinylidene fluoride-chlorofluoroethylene P(VDF-CTFE) (56 / 44 mol%) binary copolymer, replacing Gas 3 times, N,N-dimethylformamide (DMF) solvent was added under nitrogen protection, and the polymer was fully dissolved at room temperature; 4.2 mL of di-n-propylamine was added dropwise to the reaction system, and the temperature was slowly raised to 55 ° C , stirred for 1.5h; after the reaction, the reaction system was slowly cooled to room temperature, dropped dropwise into a mixed solution of ethanol and water with a volume ratio of 2:1, and the modified multi-component copolymer was precipitated to obtain the modified multi-component copolymer; repeated dissolving and washing three times, Finally, double bond modified P(VDF-CTFE) f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com