Production method of trichoderma chlamydospore

A technology for chlamydospore and production method, which is applied in the field of fermentation engineering, can solve the problems of affecting the quality of chlamydospore hyphae, can not meet the lack of carbon source, affect the activity and yield of spores, etc., and achieves storage resistance and strong stress resistance. , the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Medium ratio:

[0033] a) Potato glucose culture solution:

[0034] 200g potato extract (200g potato peeled, chopped, boiled until soft, then filtered with gauze to get the clear liquid), 20g glucose, add water to 1L

[0035] Add 1.5% (15g / L) agar to the potato dextrose agar plate on the basis of the above, and sterilize at 121°C for 25min.

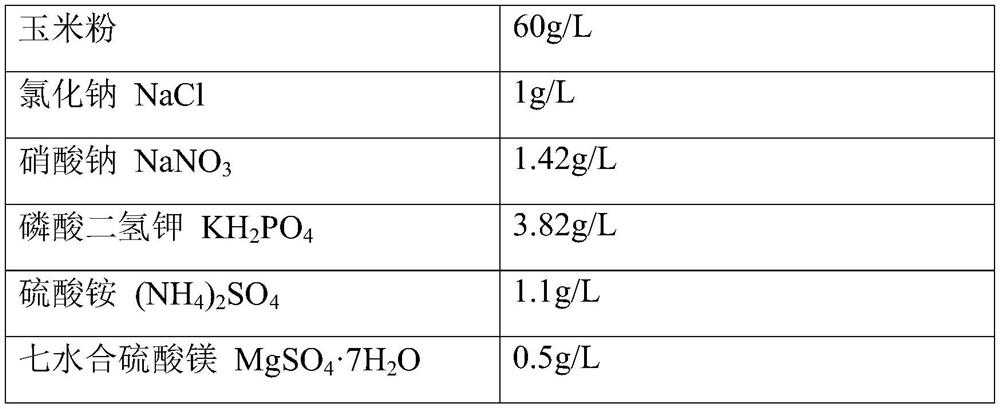

[0036] b) cornmeal medium,

[0037]

[0038]

[0039] After mixing in the fermenter, sterilize at 121°C for 30 minutes, cool to 28°C for inoculation after sterilization, and the pH value after sterilization is 5.0.

[0040] S1. Strain maintenance and seed liquid culture: Aseptically operated in a clean environment, Trichoderma harzianum strains were maintained on potato dextrose agar plates. Punch a hole on the flat plate covered with thalline and inoculate it into 500mL potato dextrose culture solution, at 28 DEG C, 120rpm shaker shaking culture for 48h, can be used for inoculating the primary fermenter (seed tank).

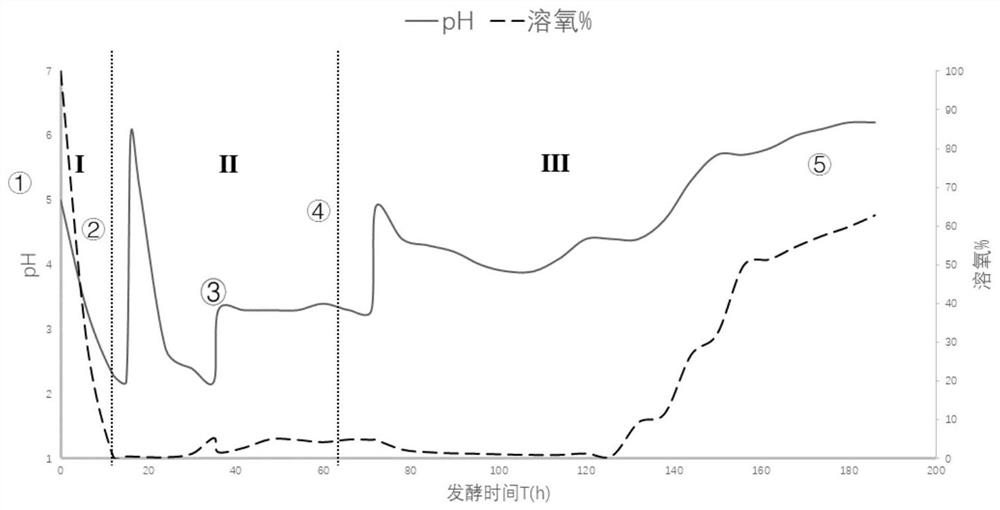

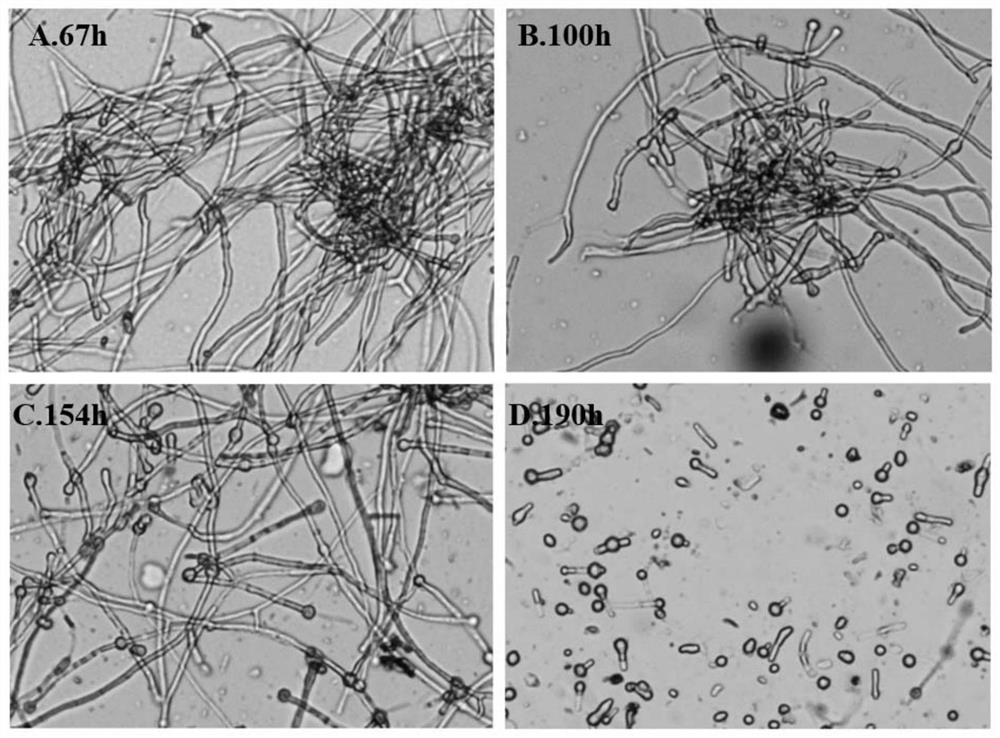

[0...

Embodiment 2

[0058] Medium ratio:

[0059] a) Potato glucose culture solution:

[0060] 200g potato extract (200g potato peeled, chopped, boiled until soft, then filtered with gauze to get the clear liquid), 20g glucose, add water to 1L

[0061] Add 1.5% (15g / L) agar to the potato dextrose agar plate on the basis of the above, and sterilize at 121°C for 25min.

[0062] b) cornmeal medium,

[0063] corn flour 60g / L Sodium chloride NaCl 1g / L Sodium nitrate NaNO 3

1.42g / L Potassium dihydrogen phosphate KH 2 PO 4

3.82g / L Ammonium sulfate (NH 4 ) 2 SO 4

1.1g / L Magnesium Sulfate Heptahydrate MgSO 4 ·7H 2 o

0.5g / L Zinc sulfate heptahydrate ZnSO 4 ·7H 2 o

0.002g / L Heptahydrate ferrous sulfate FeSO 4 ·7H 2 o

0.0075g / L Manganese Sulfate Monohydrate MnSO 4 ·H 2 o

0.0025g / L

[0064] After mixing in the fermenter, sterilize at 121°C for 30 minutes, cool to 30°C for inoculation after steri...

Embodiment 3

[0082] Medium ratio:

[0083] a) Potato glucose culture solution:

[0084] 200g potato extract (200g potato peeled, chopped, boiled until soft, then filtered with gauze to get the clear liquid), 20g glucose, add water to 1L

[0085] Add 1.5% (15g / L) agar to the potato dextrose agar plate on the basis of the above, and sterilize at 121°C for 25min.

[0086] b) cornmeal medium,

[0087] corn flour 60g / L Sodium chloride NaCl 1g / L Sodium nitrate NaNO 3

1.42g / L Potassium dihydrogen phosphate KH 2 PO 4

3.82g / L Ammonium Sulfate (NH 4 ) 2 SO 4

1.1g / L Magnesium Sulfate Heptahydrate MgSO 4 ·7H 2 o

0.5g / L Zinc sulfate heptahydrate ZnSO 4 ·7H 2 o

0.002g / L Heptahydrate ferrous sulfate FeSO 4 ·7H 2 o

0.0075g / L Manganese Sulfate Monohydrate MnSO 4 ·H 2 o

0.0025g / L

[0088] After mixing in the fermenter, sterilize at 121°C for 30 minutes, cool to 28°C for inoculation after steri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com