Cross-scale simulation method for predicting microstructure evolution in colloid shear motion process

A technology of motion process and microstructure, applied in chemical process analysis/design, instrumentation, computational theoretical chemistry, etc., to achieve the effects of reducing environmental pollution, improving research efficiency, and optimizing dissipation dynamics models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

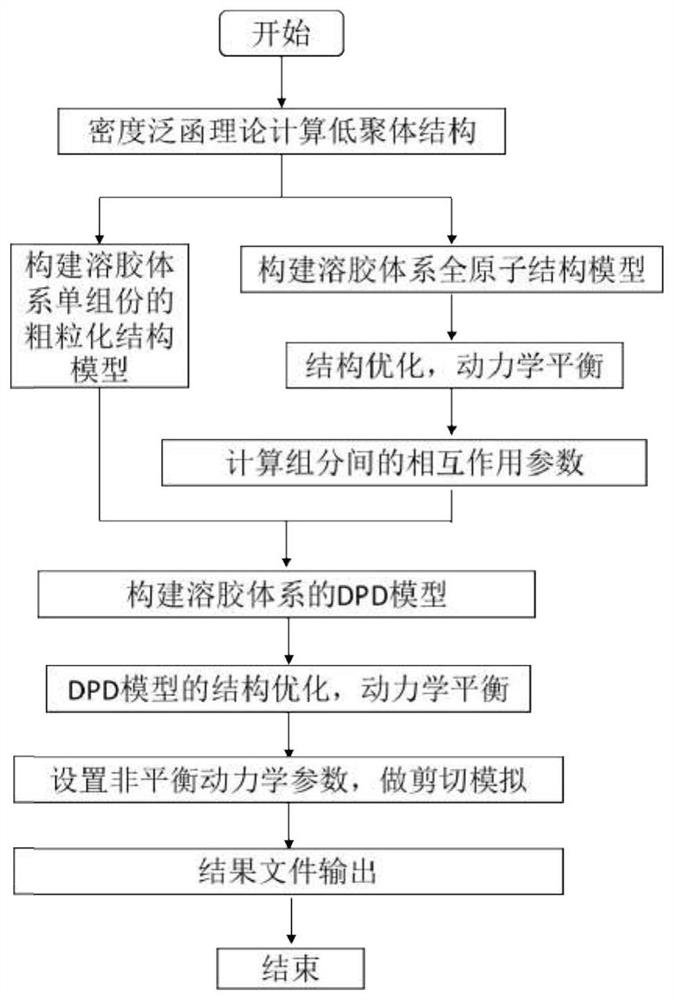

[0067] The present invention provides a cross-scale simulation method for predicting microstructure evolution during colloid shear motion, which specifically includes the following steps:

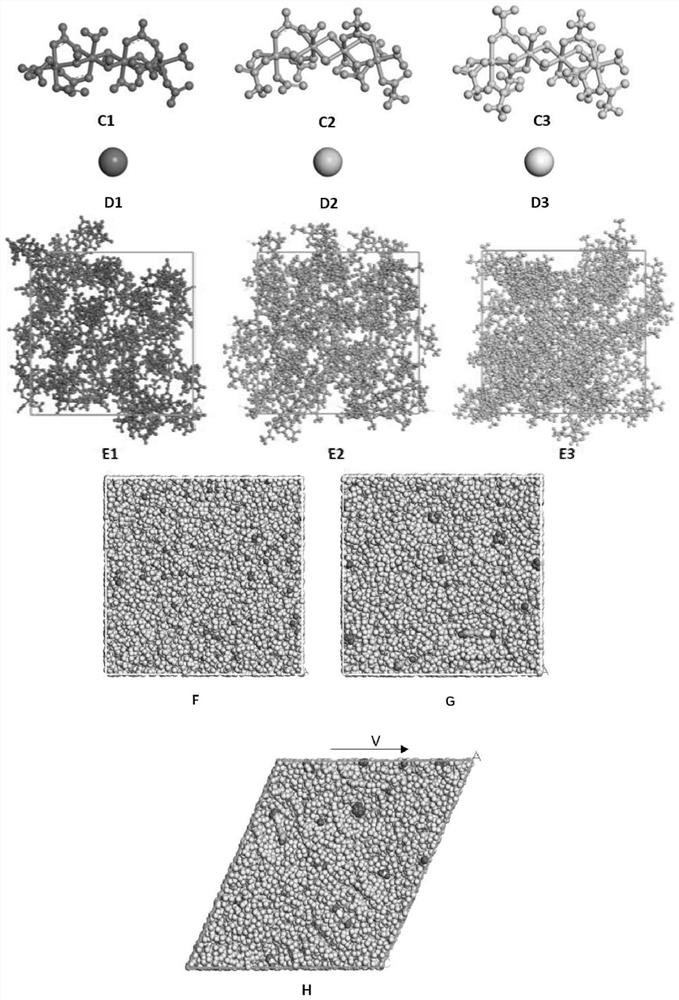

[0068] (1) Using aluminum powder, formic acid, acetic acid and deionized water as the raw material system, using density functional theory (DFT), the different oligomer structure models and parameters obtained after the reaction of the system are calculated through the Gaussian03 program. The output format of the structural formula is: *.pdb, import the file into Materials Studio, and get the structure formula as figure 1 -C1, figure 1 -C2 and figure 1 Represented by -C3, they are hydroxyaluminum diformate, hydroxyaluminum formate and hydroxyaluminum diacetate;

[0069] (2) The structural formulas of C1, C2 and C3 will be obtained, and the Materials Studio software will be used for modeling, and the oligomer coarse-grained model will be established by Build→BuildMesostructure, and the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com