A kind of bisacodyl tablet and preparation method thereof

A technology of saacodyl tablets and bisacodyl, which is applied in the field of medicine, can solve the problems of drug quality and drug efficacy stability, influence the therapeutic effect of bisacodyl, destroy the chemical structure of bisacodyl, etc. Balance, reduce water and electrolyte abnormalities with hypokalemia, and enhance immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

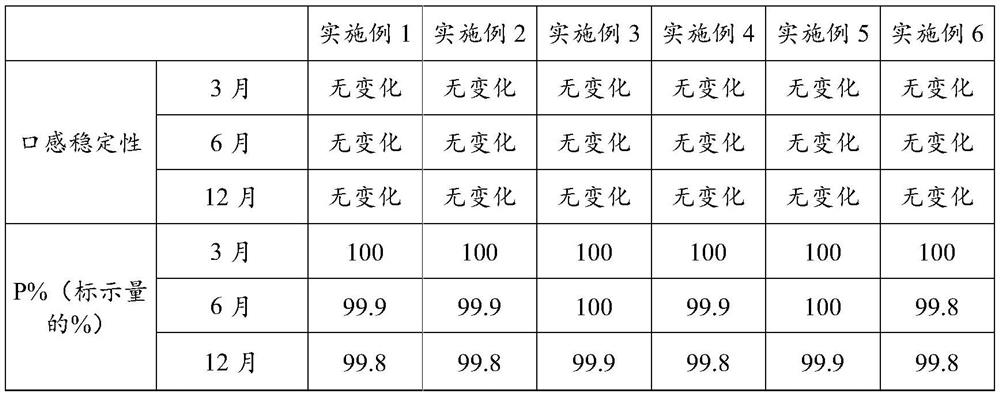

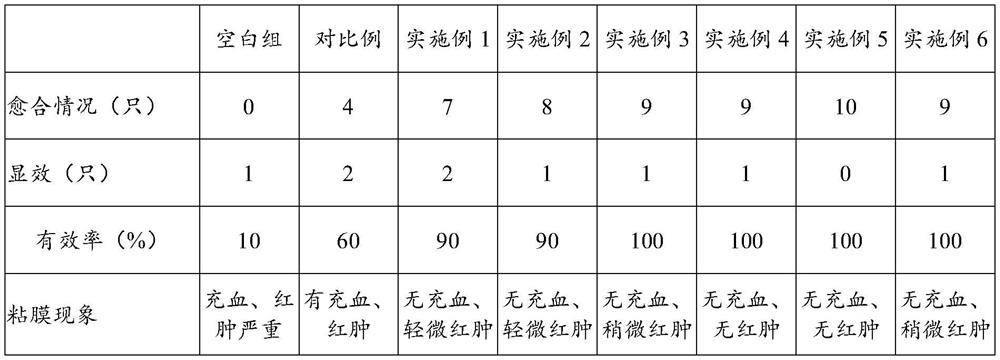

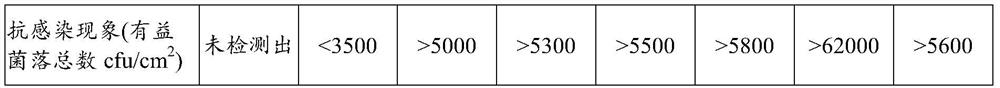

Examples

Embodiment 1

[0026] A kind of bisacodyl tablet, its preparation method comprises the following steps:

[0027] (1) First crush bisacodyl, sodium carboxymethyl starch, hypromellose, potassium bicarbonate, malic acid, pumpkin powder, millet starch, lactulose, bifidobacterium, and aloe extract respectively, and after 150- 200 mesh sieve filtration;

[0028] (2) Mix 12g of potassium bicarbonate and dissolve it in 12g of pure water. After heating to 40-50°C, add 14g of lactulose and 29g of pumpkin powder, stir at a speed of 450-600r / min, mix well, and then Dry on a fluidized bed at a temperature of 55-60°C, then grind and pulverize to 150-200 mesh to obtain mixture A;

[0029] (3) 8g of bifidobacteria, 10g of aloe extract, 20g of bisacodyl, 16g of malic acid and mixture A were stirred at a temperature of 15-20°C and a speed of 650-750r / min, and mixed uniformly to obtain mixture B;

[0030] (4) Dissolve 24g of millet starch in 60g of pure water, heat the temperature to 50-65°C and stir at a sp...

Embodiment 2

[0034] A kind of bisacodyl tablet, its preparation method comprises the following steps:

[0035] (1) First crush bisacodyl, sodium carboxymethyl starch, hypromellose, potassium bicarbonate, malic acid, pumpkin powder, millet starch, lactulose, bifidobacteria, and aloe extract respectively, and after 150- 200 mesh sieve filtration;

[0036] (2) Mix 15.2g of potassium bicarbonate and dissolve it in 12g of pure water. After heating to 40-50°C, add 10g of lactulose and 18g of pumpkin powder and stir at a speed of 450-600r / min, mix well, and then Dry on a fluidized bed at a temperature of 55-60°C, and then grind and pulverize to 150-200 mesh to obtain mixture A;

[0037] (3) 15g of bifidobacteria, 18g of aloe extract, 35g of bisacodyl, 19.2g of malic acid and mixture A were stirred at a temperature of 15-20°C and a speed of 650-750r / min, and mixed uniformly to obtain mixture B;

[0038] (4) Dissolve 15g of millet starch in 44g of pure water, heat the temperature to 50-65°C and s...

Embodiment 3

[0042] A kind of bisacodyl tablet, its preparation method comprises the following steps:

[0043] (1) First crush bisacodyl, sodium carboxymethyl starch, hypromellose, potassium bicarbonate, malic acid, pumpkin powder, millet starch, lactulose, bifidobacterium, and aloe extract respectively, and after 150- 200 mesh sieve;

[0044] (2) Mix 14.8g of potassium bicarbonate and dissolve it in 13g of pure water. After heating to 40-50°C, add 11g of lactulose and 21g of pumpkin powder and stir at a speed of 450-600r / min, mix well, and then Dry on a fluidized bed at a temperature of 55-60°C, and then grind and pulverize to 150-200 mesh to obtain mixture A;

[0045] (3) Stir 10.3g of bifidobacteria, 12.7g of aloe extract, 26.8g of bisacodyl, 48g of malic acid and mixture A at a temperature of 15-20°C and a speed of 650-750r / min, and mix uniformly to obtain a mixture B;

[0046] (4) Dissolve 16.5g of millet starch in 48g of pure water, heat the temperature to 50-65°C and stir at a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com