Microbial cracking method and kit thereof

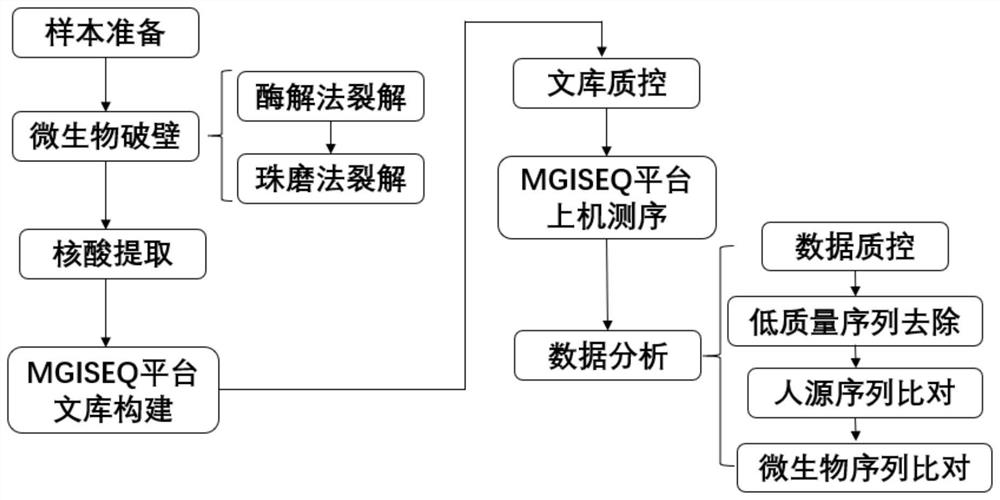

A microorganism and kit technology, applied in the field of microbial lysis methods and their kits, can solve the problems of missed pathogen detection, cell wall thickness, poor lysis effect, etc. The effect of wall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

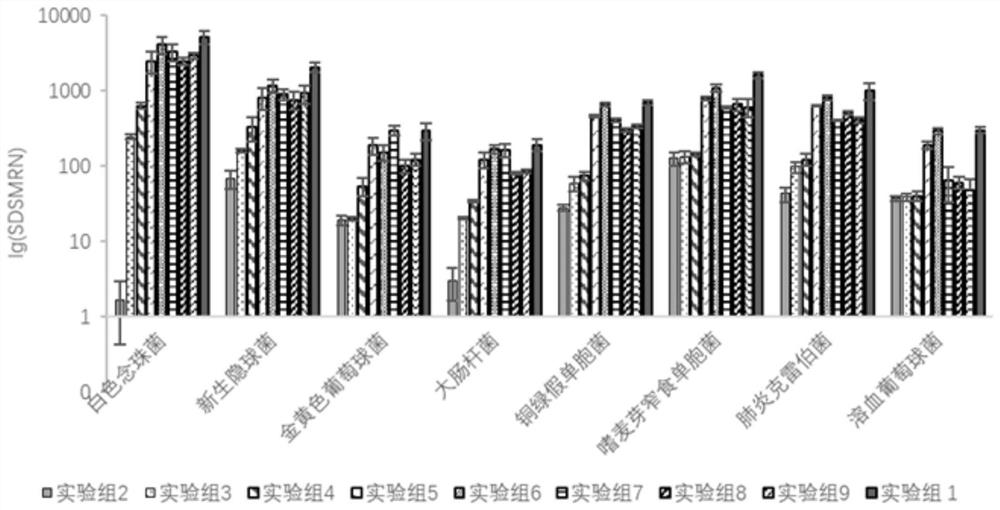

[0083] This embodiment uses the method of experimental group 1 and the method of not breaking the wall (experimental group 2), the separate enzymatic hydrolysis method (experimental group 3), the separate bead milling method (experimental group 4), the method of experimental group 5 (enzyme addition amount) respectively 4.5 μL), the method of experimental group 6 (enzyme addition amount is 12 μL), the method of experimental group 7 (glass bead diameter 1 mm), the method of experimental group 8 (glass bead volume 100 μL), the method of experimental group 9 (glass bead Volume 400μL) for parallel testing on the same sample. This embodiment uses simulated samples. In order to test the comprehensiveness of the detection process for microbial detection, when configuring the simulated samples, Staphylococcus aureus (G+), Staphylococcus hemolyticus (G+), Escherichia coli (G-), Pseudomonas aeruginosa sp. (G-), Klebsiella pneumoniae (G-), Stenotrophomonas maltophilia (G-), Candida albic...

Embodiment 2

[0100] The nucleic acid extraction reagent used in this example is the same as in Example 1.

[0101] In this example, Aspergillus fumigatus was cracked and tested. Aspergillus fumigatus (Latin name Aspergillus fumigatus) is an important pathogen, and pulmonary aspergillosis is mainly caused by Aspergillus fumigatus infection.

[0102]A case of alveolar lavage fluid sample (volume 450 μL) was taken for experiment, and the sample was obtained from human alveolar lavage with physiological saline (aqueous sodium chloride solution with a mass concentration of 0.9%). With reference to the method of Example 1, this embodiment uses the method of experimental group 1 and the non-broken treatment method (experimental group 2), the separate enzymatic hydrolysis method (experimental group 3), the separate bead milling method (experimental group 4), and the experimental group The method of 5 (enzyme addition amount is 4.5 μL), the method of experimental group 6 (enzyme addition amount is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com