Super-hydrophobic coating for alkali efflorescence resistance of cement mortar and preparation method of super-hydrophobic coating

A super-hydrophobic coating and cement mortar technology, applied in cement coatings, coatings, etc., can solve the problems of easy wear, wide spacing, mechanical wear of micro-column structures, etc., to achieve mechanical wear resistance, simple preparation process, and reduce water absorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 50g of 52.5-stage white silicate cement, 100g over 100 mesh sieve net sand, 3g iron oxide red brown powder, dry material slowly mixed 30s; add 25 g of water and stir 30S; stand 60s The mixed cement mortar was coated on a cement mortar substrate, and the prepared cement coating was about 1.2 mm.

[0028] (2) After drying, the cement coating is dried, and the prepared hydrophobic emulsion is applied to the surface of the cement mortar, and the excess emulsion is removed by plastic silica gel squeezed knife, at 50 ° C drying 1-2d, it can obtain supergraphic cement mortar, The water contact angle is 153 ± 0.5 °. The formulation of the hydrophobic emulsion is shown in Table 1 below.

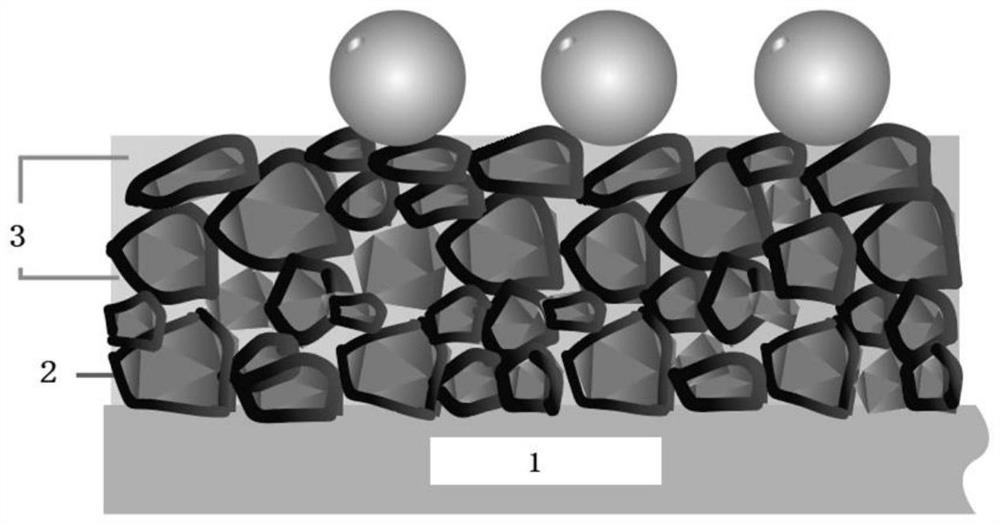

[0029] like figure 1 As shown, a schematic diagram of the preparation principle of a cement mortar superhydrophobic coating. The surface of the cement substrate is covered by microscopic sand and micro-nanoscale cement particles and hydrated products to construct the rough structure of superhym...

Embodiment 2

[0031] (1) 50g of 52.5-stage white silicate cement, 137.5 g of the 3-mesh screen sand, 3g iron oxide red brown powder, dry material, dry material, add 25 g of water and stir-stirred 30s; 60S, the mixed cement mortar was coated on the cement mortar substrate, and the prepared cement coating was about 1.5 mm.

[0032] (2) The above cement coating is dried, and the prepared hydrophobic emulsion is applied to the surface of the cement mortar, and the excess emulsion is removed by plastic silica gel shank, and the superhydrophilic cement mortar can be obtained from 50 ° C. The contact angle is 150 ± 0.4 °. The formulation of the hydrophobic emulsion is shown in Table 1 below.

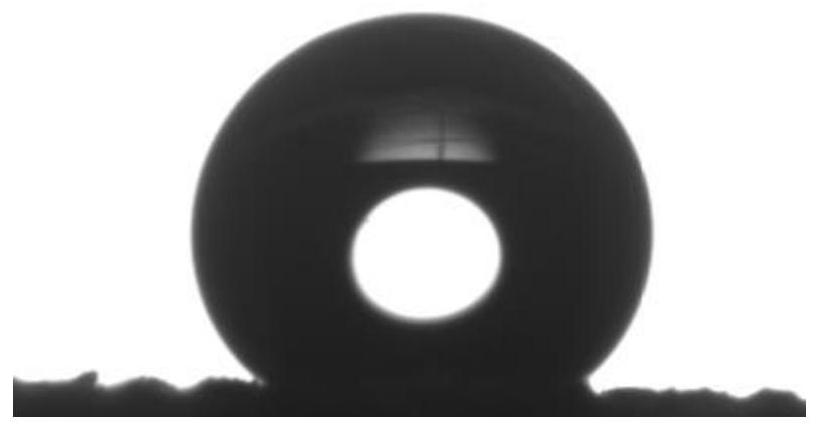

[0033] figure 2 A surface static water contact angle measurement of the superhydrophilic emulsion coating prepared in Example 2, and its water contact angle is 150 ± 0.4 °.

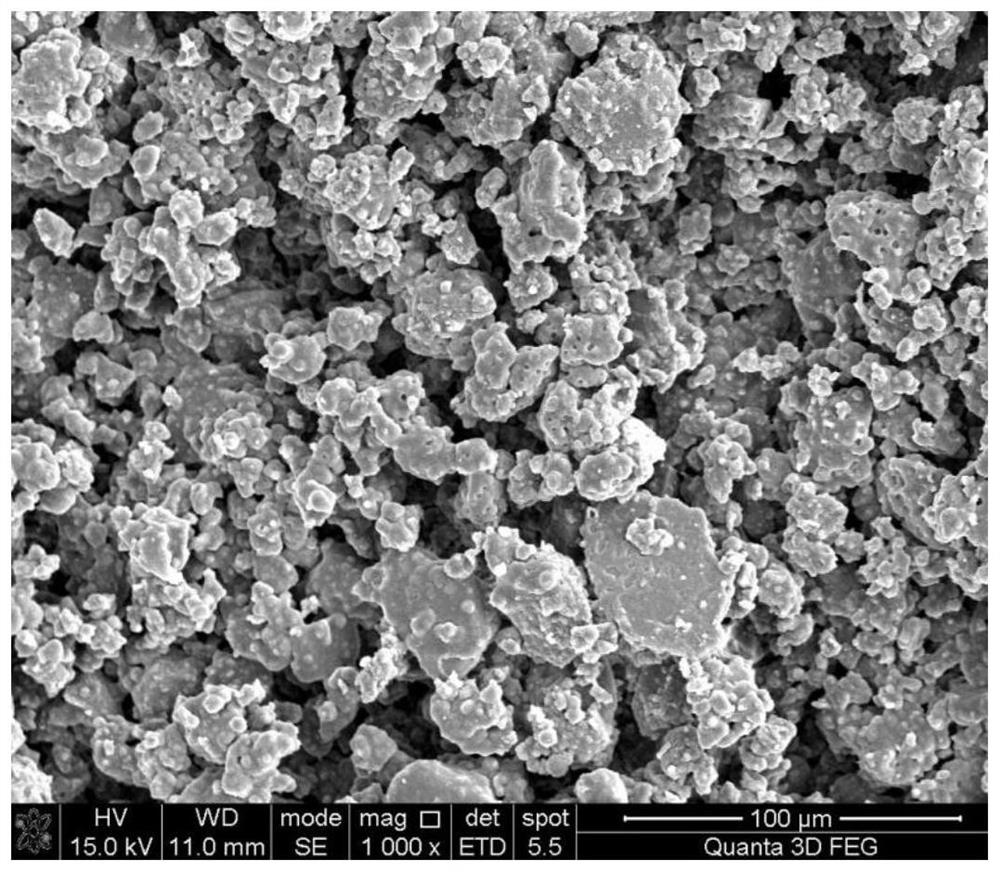

[0034] image 3 For Example 2, the surface of the superhydrophilic emulsion coating is 100 microns of SEM, which is an ultra-slim cement ...

Embodiment 3

[0036](1) 50g of 52.5-stage white silicate cement, 125g over 50 mesh sieve net sand, 3.6 g of iron oxide red brown powder, dry material slowly mixed 30S; add 30 g of water and stir 30S; 60S, the mixed cement mortar was coated on the cement mortar substrate, and the prepared cement coating was about 1.3 mm.

[0037] (2) The above cement coating is dried, and the prepared hydrophobic emulsion is applied to the surface of the cement mortar, and the excess emulsion is removed by plastic silica gel shank, and the superhydrophilic cement mortar can be obtained from 50 ° C. The contact angle is 155 ± 0.7 °. The formulation of the hydrophobic emulsion is shown in Table 1 below.

[0038] Figure 4 For example, the surface contact angle of cement mortar ultra-hydrophobic coating with the number of frictions. After 30 cycles of friction, the superhydrophilic cement mortar sample has a surface layered rough structure that is more stable, and the contact angle is maintained between 155 ± 0.7 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com