Early-strength functional monomer and preparation method thereof, and early-strength polycarboxylate superplasticizer and preparation method thereof

A technology of functional monomers and polycarboxylic acids, applied in the field of concrete admixtures, can solve problems such as limited early strength effect, increased heat release of cement, increased concrete viscosity, etc., and is conducive to promotion and popularization, and improved hydration rate , Improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

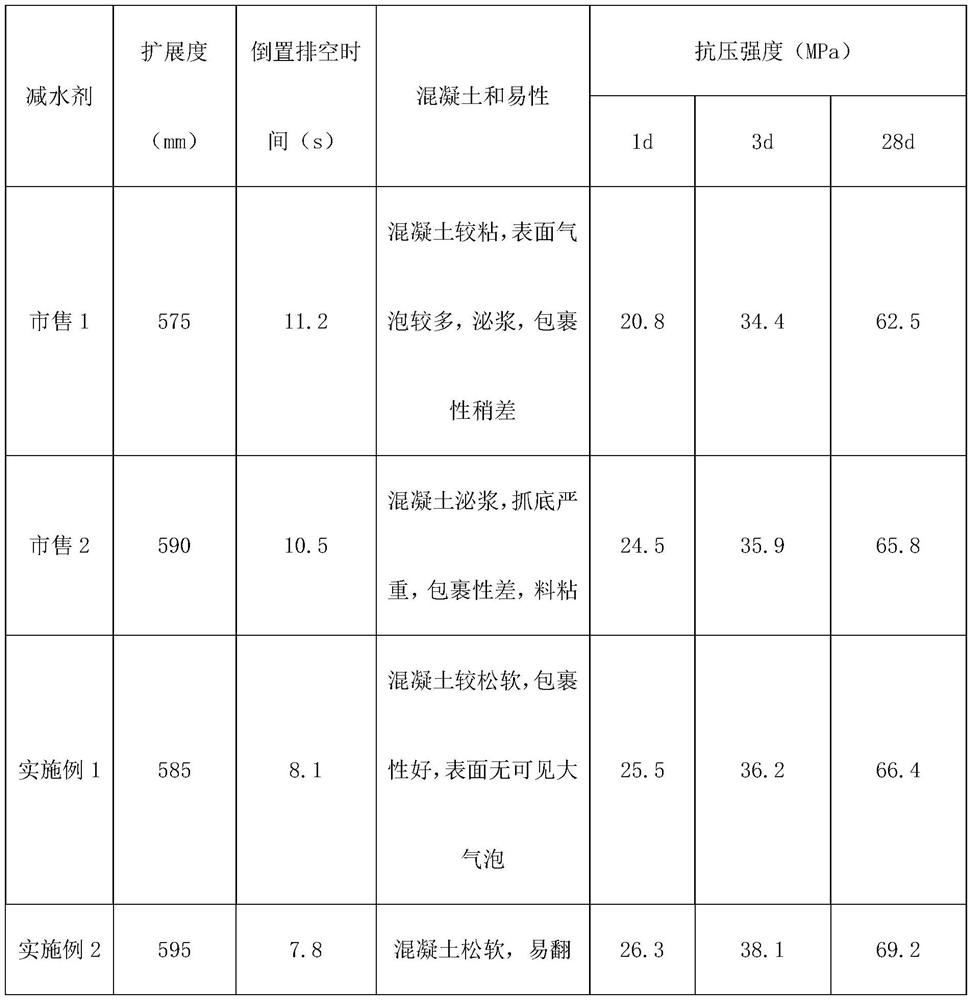

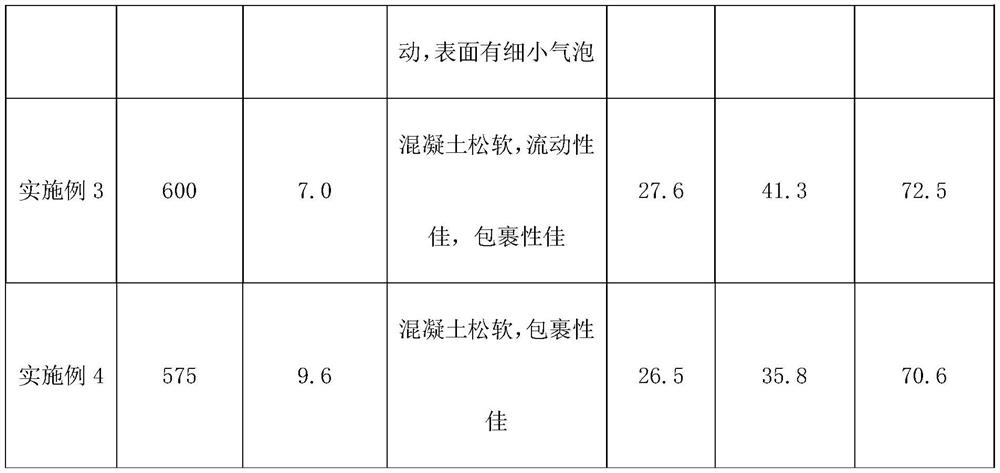

Examples

Embodiment 1

[0037] The preparation method of the early-strength polycarboxylate water reducer of the present invention, the preparation method comprises the following steps:

[0038] (1) Synthesis of early-strength functional monomers:

[0039] In a four-necked flask with a stirrer, a thermometer, and a reflux condenser, add 129 g of prenyl alcohol, then add 277 g of 4-aminophenylazobenzene-3-sulfonic acid, and stir evenly to make the two raw materials Fully blend, then add 12.18g of p-toluenesulfonic acid and 3.25g of hydroquinone into the reaction vessel, slowly raise the temperature to 100°C while stirring, carry out reflux reaction for 7.5h, and cool down to 40°C after the reaction. Neutralize with sodium bicarbonate solution until the liquid is neutral, extract with water for 3 times, recover the organic phase, dry with anhydrous sodium sulfate for 12 hours, filter off the solvent, then distill until there is no liquid and continue to drop at the condenser. The ester early-strength ...

Embodiment 2

[0044] The preparation method of the early-strength polycarboxylate water reducer of the present invention, the preparation method comprises the following steps:

[0045] (1) Synthesis of early-strength functional monomers:

[0046] In a four-necked flask with stirrer, thermometer, and reflux condenser, add 115g of isobutenol, then add 257g of 5-[(4-aminophenyl) azo]-2-hydroxybenzoic acid, stir well, make The two raw materials are fully fused, and then 10.42g of phosphoric acid and 2.23g of phenothiazine are added to the reaction vessel, and the temperature is slowly raised to 100°C while stirring, and the reflux reaction is carried out for 6 hours. The sodium solution is neutralized until the liquid is neutral, extracted with water for 3 times, the organic phase is recovered, dried with anhydrous sodium sulfate for 12 hours, and the solvent is filtered off, and then distilled until there is no liquid, continue to drop at the condenser tube, and the distilling bottle The este...

Embodiment 3

[0051] The preparation method of the early-strength polycarboxylate water reducer of the present invention, the preparation method comprises the following steps:

[0052] (1) Synthesis of early-strength functional monomers:

[0053] In a four-necked flask with stirrer, thermometer, and reflux condenser, add 170g of 4-methyl-4-pentenol, then add 307g of 3-[(4-amino-3-methoxyphenyl) Azo]-benzenesulfonic acid, stir evenly, make two kinds of raw materials fully blend, then add the toluenesulfonic acid of 13.34g and the tert-butylcatechol of 3.82g in the reaction container, slowly heat up to 100 while stirring ℃, carry out reflux reaction for 7.5h, after the reaction is completed, cool down to 40°C, neutralize with sodium bicarbonate solution until the liquid is neutral, recover the organic phase, dry with anhydrous sodium sulfate for 12h, filter off the solvent, and then carry out distillation. Distill until there is no liquid and continue to drop at the condenser, and the ester ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com