Moisture cured polyurethane modified cold-mixed asphalt and preparation method thereof

A technology of polyurethane modification and cold-mix asphalt, which is applied in building components, building insulation materials, buildings, etc. It can solve the problems of low stability of cold-mix asphalt, long curing time, complicated process, etc., and achieve convenient and easy construction Good, good curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

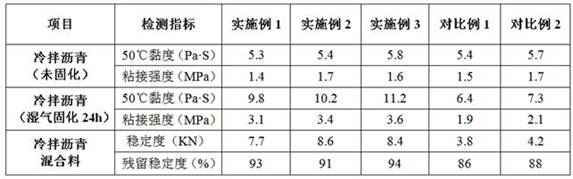

Examples

Embodiment 1

[0026] A kind of moist curing polyurethane modified cold mix asphalt and its preparation method, the steps are as follows:

[0027] (1) Add 1 part (parts by weight, the same below) of toluene diisocyanate (TDI) into the reactor and raise the temperature to 80°C, add 4 parts of polypropylene glycol with a molecular weight of 1500 into the reactor in two times, maintain the temperature at 80°C and stir the reaction 90min, obtained isocyanate-terminated linear polyurethane prepolymer;

[0028] (2) Add 70 parts of base asphalt into the shearing stirring tank and heat it to 100°C to make it completely melted, then add 15 parts of diesel oil, 3 parts of polyethylene wax, 5 parts of polyurethane prepolymer, and 1 part of calcium chloride desiccant in sequence. Shear mixing at 1500r / min for 90min to prepare polyurethane modified cold mix asphalt;

[0029] (3) Cool the polyurethane-modified cold-mix asphalt to 70°C, add 2 parts of sulfur powder stabilizer, 0.5 part of methyl isopropyl...

Embodiment 2

[0031] A kind of moist curing polyurethane modified cold mix asphalt and its preparation method, the steps are as follows:

[0032] (1) Add 2 parts of diphenylmethane diisocyanate (MDI) into the reactor and raise the temperature to 90°C, and add 8 parts of ethylene glycol-propylene glycol-ethylene glycol triblock copolymer with a molecular weight of 2000 into the reactor in two times , maintaining the temperature at 90°C and stirring for 60 minutes to prepare the isocyanate-terminated linear polyurethane prepolymer;

[0033] (2) Add 75 parts of base asphalt to the shearing stirring tank and heat it to 120°C to make it completely melted, then add 20 parts of 200# solvent oil, 2 parts of dioctyl phthalate, 10 parts of polyurethane prepolymer, 4 parts Magnesium sulfate desiccant, shear and mix for 60 minutes at a rate of 2000r / min, to obtain polyurethane modified cold mix asphalt;

[0034] (3) Cool the polyurethane-modified cold-mix asphalt to 80°C, add 3 parts of cellulose stab...

Embodiment 3

[0036] A kind of moist curing polyurethane modified cold mix asphalt and its preparation method, the steps are as follows:

[0037] (1) Add 3 parts of hexamethylene diisocyanate (HDI) into the reactor and raise the temperature to 70°C, add 12 parts of polytetrahydrofuran ether diol with a molecular weight of 1200 into the reactor in three times, maintain the temperature at 70°C and stir for 120 minutes. Prepared isocyanate-terminated linear polyurethane prepolymer;

[0038] (2) Add 60 parts of base asphalt into the shearing stirring tank and heat it to 90°C to make it completely melted, then add 10 parts of 180# solvent oil, 5 parts of sasobit resin, 15 parts of polyurethane prepolymer, and 3 parts of quicklime desiccant in sequence. Shear mixing at 1000r / min for 120min to prepare polyurethane modified cold mix asphalt;

[0039] (3) Cool the polyurethane modified cold mix asphalt to 60°C, add 1 part of rubber oil stabilizer, 1.5 parts of acetophenone-m-phenylenediamine type k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com