High-gloss wear-resistant environment-friendly low-odor water-based gloss oil and preparation method thereof

A water-based varnish and low-odor technology, applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., to reduce surface tension, reduce environmental pollution, and enhance mutual repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

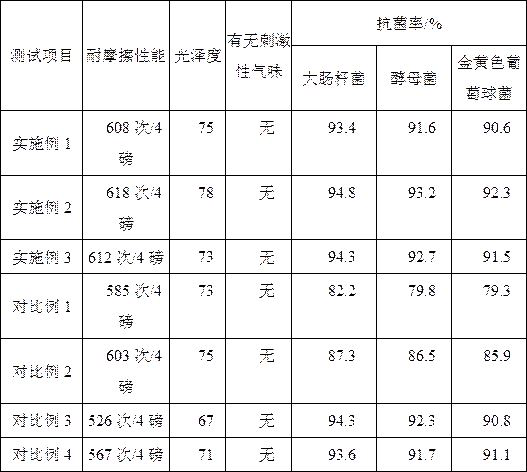

Examples

Embodiment 1

[0031] A high-gloss, wear-resistant, environmentally friendly, low-odor water-based varnish, the water-based varnish is composed of the following components in parts by weight: 60 parts of water-based acrylate emulsion, 12 parts of styrene-acrylate resin emulsion, 5 parts of carnauba wax emulsion, 3 parts of ten Sodium dialkylbenzenesulfonate, 1.2 parts of polyvinyl alcohol, 2.0 parts of propylene glycol methyl ether, 2 parts of polydimethylsiloxane, 0.3 parts of antifoaming agent, 1.2 parts of wetting agent, 0.8 parts of plant antibacterial agent and 10 parts Mixture.

[0032] The water-based acrylate emulsion is composed of the following raw materials in weight percentage: 50% acrylic resin, 25% absolute ethanol, 10% ammonia solution with a concentration of 20% and 15% demineralized water.

[0033] The defoamer is polyoxyethylene polyoxypropylene pentaerythritol ether.

[0034] The preparation method of the wetting agent is as follows: put 25 parts by weight of lauric acid ...

Embodiment 2

[0046] The water-based varnish provided by the present embodiment and the preparation method are roughly the same as in Example 1, and its main difference is:

[0047] A high-gloss, wear-resistant, environmentally friendly, low-odor water-based varnish, the water-based varnish is composed of the following components in parts by weight: 70 parts of water-based acrylate emulsion, 15 parts of styrene-acrylate resin emulsion, 7 parts of carnauba wax emulsion, 5 parts of ten Sodium dialkylbenzene sulfonate, 1.5 parts of polyvinyl alcohol, 3.0 parts of propylene glycol methyl ether, 3 parts of polydimethylsiloxane, 0.5 parts of antifoaming agent, 1.5 parts of wetting agent, 1.0 part of plant antibacterial agent and 15 parts Mixture.

[0048] The water-based acrylate emulsion is composed of the following raw materials in weight percentage: 50% acrylic resin, 25% absolute ethanol, 10% ammonia solution with a concentration of 20% and 15% demineralized water.

[0049] The defoamer is p...

Embodiment 3

[0057] The water-based varnish provided by the present embodiment and the preparation method are roughly the same as in Example 1, and its main difference is:

[0058] A high-gloss, wear-resistant, environmentally friendly, low-odor water-based varnish, the water-based varnish is composed of the following components in parts by weight: 75 parts of water-based acrylate emulsion, 18 parts of styrene-acrylate resin emulsion, 9 parts of carnauba wax emulsion, 6 parts of ten Sodium dialkylbenzene sulfonate, 1.8 parts of polyvinyl alcohol, 3.8 parts of propylene glycol methyl ether, 4 parts of polydimethylsiloxane, 0.8 parts of antifoaming agent, 1.8 parts of wetting agent, 1.3 parts of plant antibacterial agent and 20 parts Mixture.

[0059] The water-based acrylate emulsion is composed of the following raw materials in weight percentage: 50% acrylic resin, 25% absolute ethanol, 10% ammonia solution with a concentration of 20% and 15% demineralized water.

[0060] The defoamer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com