Preparation of composite photocatalyst and application of composite photocatalyst in purification of VOCs

A photocatalyst and catalyst technology, applied in the field of environmental pollution control, can solve the problems of affecting the catalytic efficiency, reducing the diffusion rate of substances, increasing the mass transfer resistance, etc., to achieve the effects of accelerating the diffusion rate, enhancing the adsorption performance, and promoting the transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

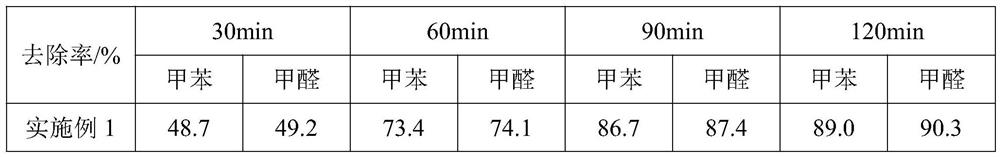

Embodiment 1

[0037] A kind of composite photocatalyst, its preparation method comprises the following steps:

[0038] S1. Weigh 2.0g of polyvinylpyrrolidone, 0.6g of azodicyanovaleric acid and 3.0g of styrene respectively, add 25ml of ethanol aqueous solution with a volume ratio of 2:1 after mixing, stir well and heat, and heat up to within 30min Boiling, reflux reaction under stirring conditions for 24h, after cooling, centrifuge to separate the precipitate, wash the precipitate with methanol and / or deionized water and then disperse in methanol to obtain suspension A, and the dispersion ratio of the precipitate is 3mg / ml;

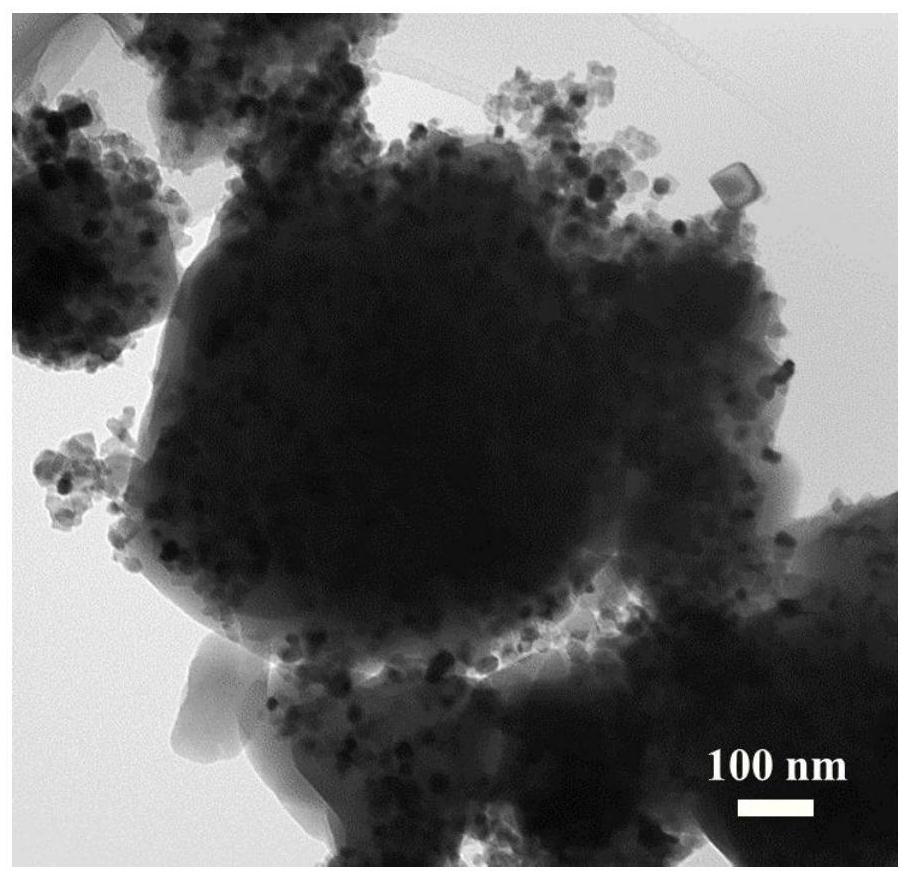

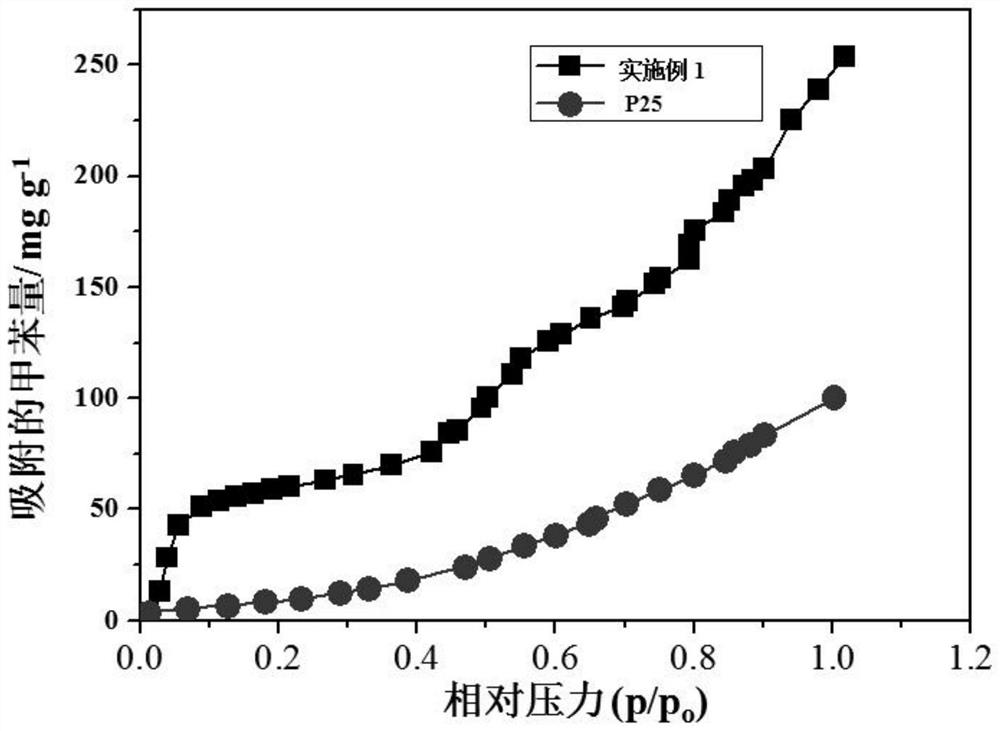

[0039] S2. Weigh 2.0 g of polyvinylpyrrolidone and completely dissolve it in 40 ml of methanol, add 0.5 g of nano-titanium dioxide (P25), stir for 20 minutes, centrifuge and separate the precipitate, wash the precipitate with methanol and / or deionized water, dry, and then disperse in In the suspension A, the suspension B was obtained, and the precipitation dispersion r...

Embodiment 2

[0044] A kind of composite photocatalyst, its preparation method comprises the following steps:

[0045] S1. Weigh 2.0g of polyvinylpyrrolidone, 0.6g of azodicyanovaleric acid and 3.0g of styrene respectively, add 25ml of ethanol aqueous solution with a volume ratio of 2:1 after mixing, stir well and heat, and heat up to within 30min Boiling, reflux reaction under stirring conditions for 24h, after cooling, centrifuge to separate the precipitate, wash the precipitate with methanol and / or deionized water and then disperse in methanol to obtain suspension A, and the dispersion ratio of the precipitate is 3mg / ml;

[0046] S2. Weigh 2.0 g of polyvinylpyrrolidone and completely dissolve it in 40 ml of methanol, add 0.5 g of reduced titanium dioxide, stir for 20 minutes, centrifuge to separate the precipitate, wash the precipitate with methanol and / or deionized water, dry it, and then disperse it in the In the above-mentioned suspension A, obtain suspension B, the precipitation disp...

Embodiment 3

[0051] A kind of composite photocatalyst, its preparation method comprises the following steps:

[0052] S1. Weigh 2.0g of polyvinylpyrrolidone, 0.6g of azodicyanovaleric acid and 3.0g of styrene respectively, add 25ml of ethanol aqueous solution with a volume ratio of 2:1 after mixing, stir well and heat, and heat up to within 30min Boiling, reflux reaction under stirring conditions for 24h, after cooling, centrifuge to separate the precipitate, wash the precipitate with methanol and / or deionized water and then disperse in methanol to obtain suspension A, and the dispersion ratio of the precipitate is 3mg / ml;

[0053] S2. Weigh 2.0g of polyvinylpyrrolidone and completely dissolve it in 40ml of methanol, add 0.5g of reduced titanium dioxide and 0.14g of cadmium-cobalt bimetallic sulfide solid solution, stir for 20min, centrifuge and precipitate, and the precipitate is washed with methanol and / or After washing with deionized water, drying, and then dispersing in the suspension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com