Construction method of high-yield strain for transforming abinogen by using glucose

A technology for glucose conversion and high-yielding strains, which is applied in the field of Bacillus subtilis genetic engineering, and can solve problems such as the inability to synthesize the target product Fenggenin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

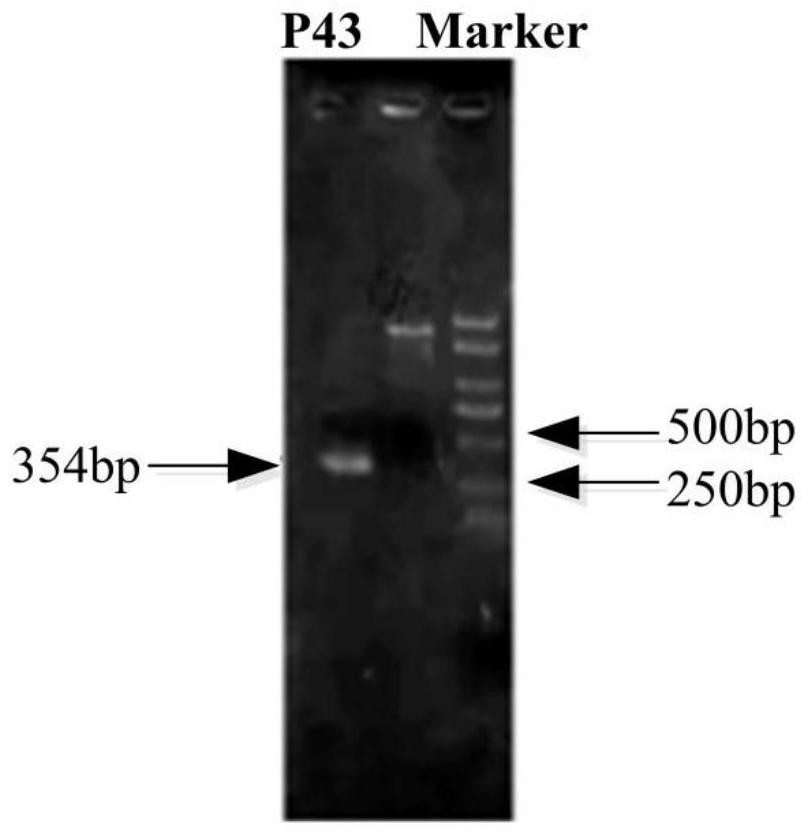

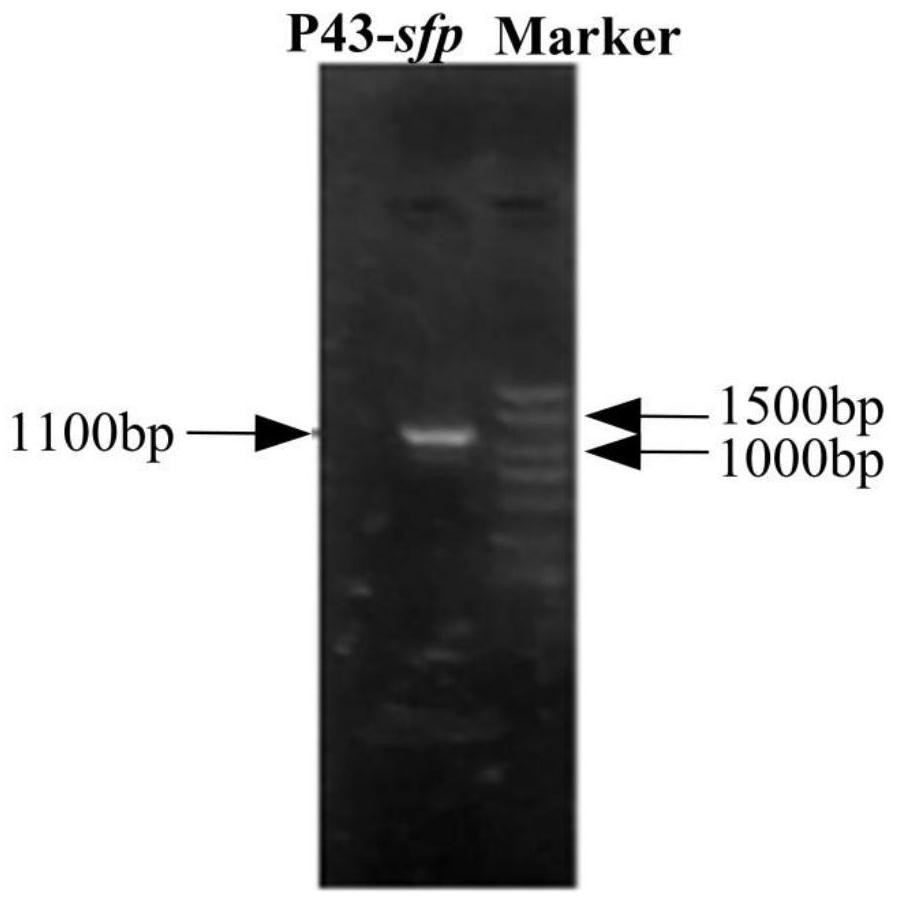

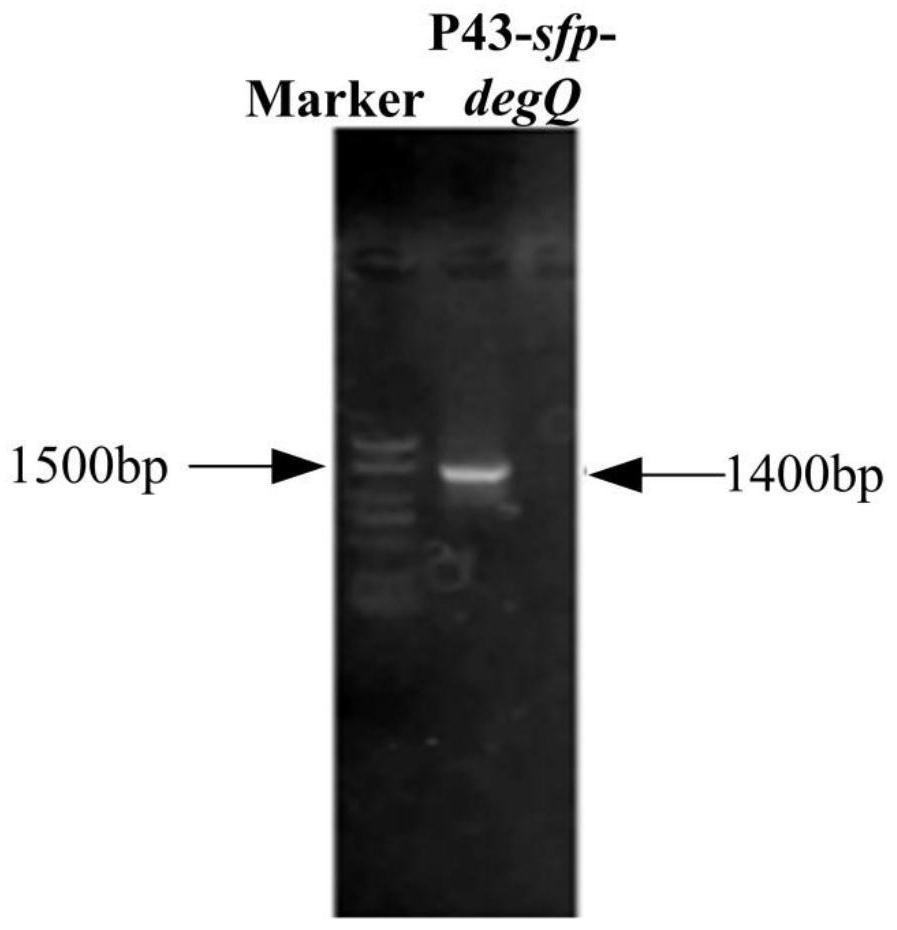

[0042] Example 1: Construction of Fengyuansu Synthetic Strain BSP000

[0043] (1) Design and synthesis of P43 promoter amplification primers. According to the nucleotide sequence of the P43 promoter, its nucleotide sequence is shown in SEQ ID NO: 1, and the amplification primers were designed as follows (the underlined line indicates the restriction site), and the primers were synthesized by Qingke Biotechnology Co., Ltd.

[0044] P43-F1:CCC AAGCTT GCGGCTTCCTTGTAGAGCTCAGC(HindⅢ)

[0045] P43-R1:

[0046] CGC GGATCC CTCGAGACGCGTGCATGCTCTAGAAGATCTCTGCAGGTCGACCATGTGTACATTCCTCTC(BamHI)

[0047] (2) Extraction of Bacillus subtilis 168 genome. Collect 3-5mL of overnight cultured Bacillus subtilis bacteria solution in a centrifuge tube, centrifuge at 12000rpm for 1min, discard the supernatant, and collect the bacterial precipitate. Add 1 mL of sterile water to the centrifuge tube to suspend the precipitate, centrifuge at 12,000 rpm for 1 min, discard the supernatant, and repe...

Embodiment 2

[0060] Example 2: Construction of Fengyuansu high-yielding strain BSP003

[0061] (1) For the BSP000 strain, collect all the gene-protein-reaction information of the strain from the database, and after optimization such as filling in missing reactions and removing redundant reactions, construct a genome-scale network metabolic model of the BSP000 strain, and then use the flux balance Three overexpression targets of accA, cypC and gapA were simulated by analysis (FBA) and minimal metabolic modulation (MOMA) algorithms.

[0062] (2) Design and synthesis of P43 promoter, accA, cypC and gapA gene amplification primers. Respectively according to accA gene (its nucleotide sequence is shown in SEQ ID NO:5), cypC gene (its nucleotide sequence is shown in SEQ ID NO:6) and gapA gene (its nucleotide sequence is shown in SEQ ID NO : 7) nucleic acid sequence, the amplification primers are designed as follows (the underlined line indicates the restriction site), and the primers are synthes...

Embodiment 3

[0074] Embodiment three: the cultivation and fermentation of BSP000 and BSP003 bacterial strains

[0075] (1) Culture medium composition:

[0076] Seed medium: tryptone 10g / L, yeast extract powder 5g / L, NaCl 10g / L, pH 7.0;

[0077] Fermentation medium: glucose 20g / L, peptone 20g / L, MgSO 4 ·7H 2 O 0.5g / L, Na 2 HPO 4 2H 2 O0.4g / L, NaH 2 PO 4 0.154g / L, pH 7.2-7.4.

[0078] (2) Cultivation and fermentation of BSP000 and BSP003 strains. The fengyuansu synthetic strain BSP000 and the fengyuansu high-yielding strain BSP003 of the present invention were respectively connected to LB liquid medium at 37°C for activation and culture for 12-14 hours, and the bacterial liquid was taken to continue to be cultured on a solid plate, and cultured upside down at 37°C for 16 hours , take the colony with larger diameter, carry out seed culture in 50mL seed culture medium with liquid filling capacity, cultivate at 37°C and 220rpm / min for 12h, obtain seed liquid, and inoculate it into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com