Li-M-X-based solid-state lithium battery positive electrode and preparation method thereof

A technology of solid lithium and solid electrolyte, which is applied in the positive electrode of Li-M-X based solid lithium battery and its preparation field, can solve the problems of large charge transfer resistance, inability to disperse evenly with each other, unfavorable large-scale production of lithium battery, etc., and achieve reduction Charge transfer resistance, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

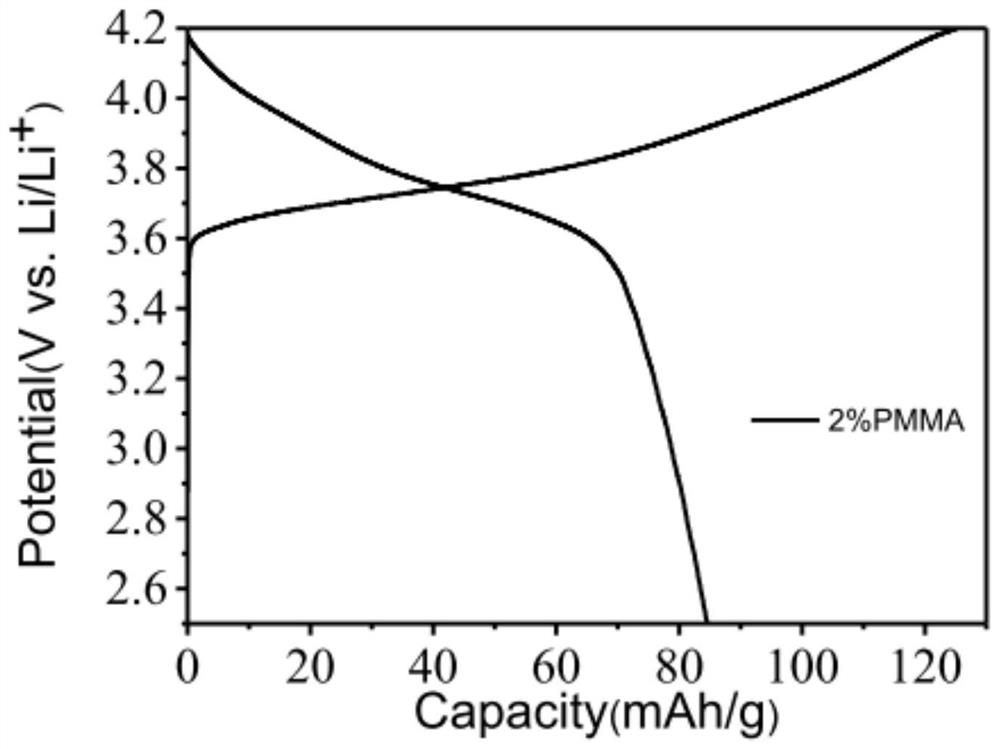

[0030] (1) Dissolve 2% polymethyl methacrylate in an appropriate amount of toluene solution.

[0031] (2) 75% nickel-cobalt-manganese ternary material, 15% Li 3 InCl 6 A solid electrolyte and 8% Ketjen Black were added to the solution obtained in step (1) to prepare a slurry.

[0032] (3) Coat the slurry obtained in (2) evenly on the carbon-coated aluminum foil, and then dry it at 60° C. for 24 hours.

[0033] (4) The dried positive electrode sheet is sintered and then compacted.

[0034] The positive electrode of the obtained Li3InCl6-based solid-state lithium battery is discharged between 2.5 and 4.2V, and the first cycle capacity is 84mA h g -1 , The capacity retention rate after 100 cycles of charge and discharge is 75%.

Embodiment 2

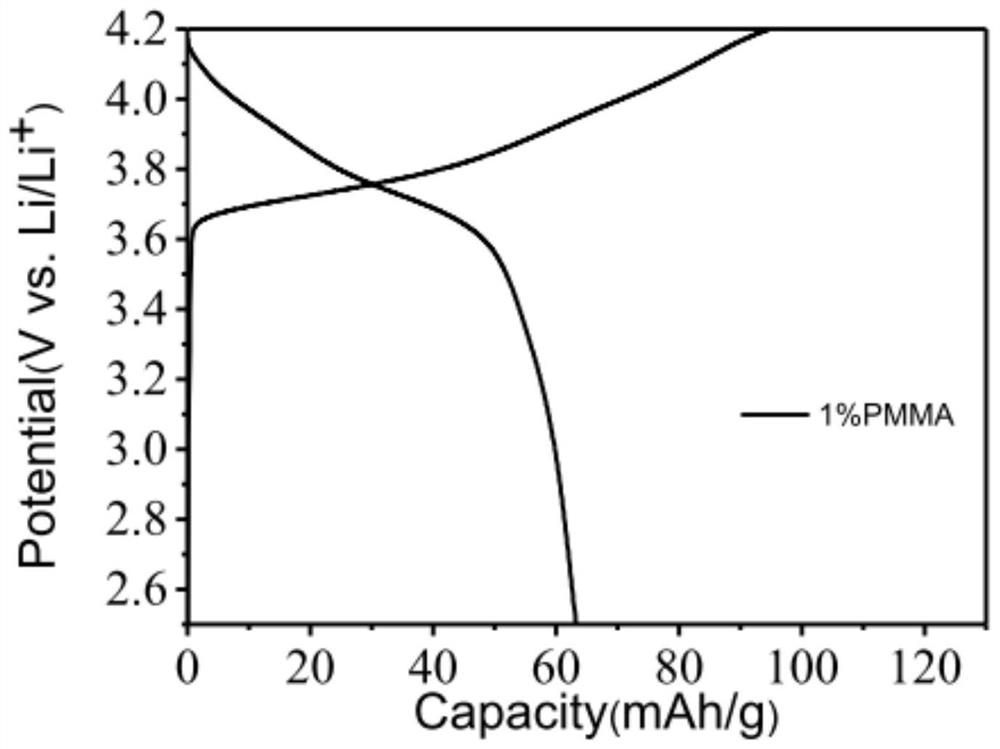

[0036] (1) Dissolve 1% polymethyl methacrylate in an appropriate amount of toluene solution.

[0037] (2) 75% nickel-cobalt-manganese ternary material, 15% Li 3 InCl 6 A solid electrolyte and 9% Ketjen Black were added to the solution obtained in step (1) to prepare a slurry.

[0038] (3) Apply the slurry obtained in (2) evenly on the charcoal-coated filter, and then dry it naturally.

[0039] (4) The dried positive electrode sheet is sintered and then compacted.

[0040] The obtained Li 3 InCl 6 The positive electrode of the solid-state lithium battery, the battery formed is discharged between 2.5 ~ 4.2V, and the capacity of the first cycle is 62mA h g -1 , The capacity retention rate after 100 cycles of charge and discharge is 57%.

Embodiment 3

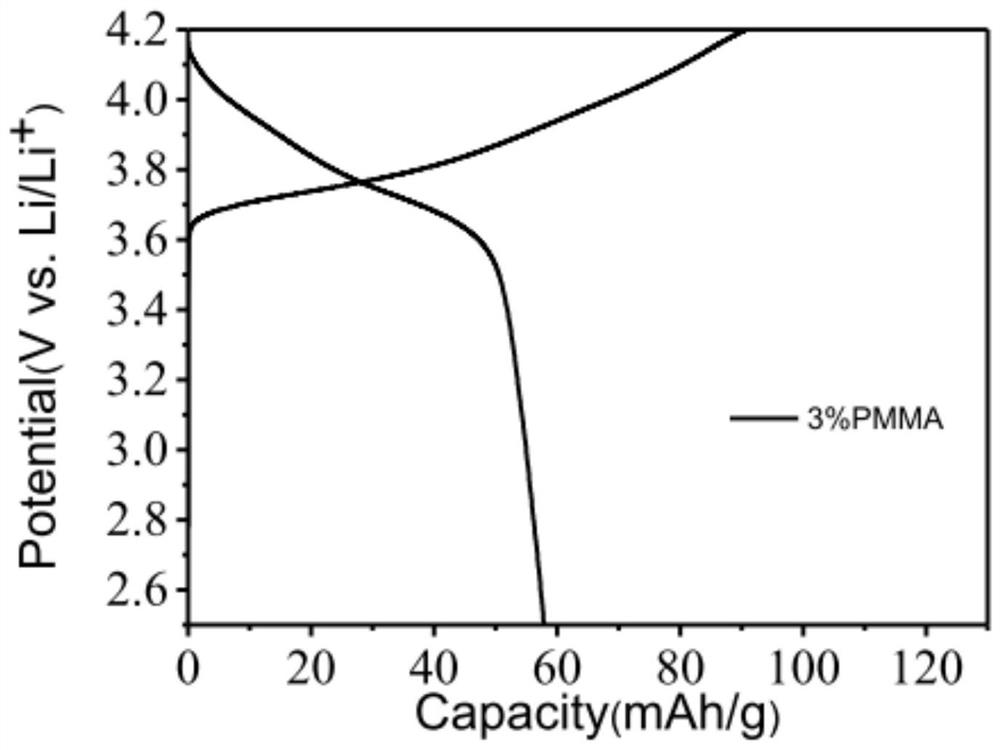

[0042] (1) Dissolve 3% polymethyl methacrylate in an appropriate amount of toluene solution.

[0043] (2) 75% nickel-cobalt-manganese ternary material, 15% Li 3 InCl 6 A solid electrolyte and 7% Ketjen Black were added to the solution obtained in step (1) to prepare a slurry.

[0044] (3) Coat the slurry obtained in (2) evenly on the charcoal-coated filter, and then dry it at 60° C. for 24 hours.

[0045] (4) The dried positive electrode sheet is sintered and then compacted.

[0046] The obtained Li 3InCl 6 The positive electrode of the base solid-state lithium battery, the battery formed is discharged between 2.5 ~ 4.2V, and the capacity of the first cycle is 57mA h g -1 , The capacity retention rate after 100 cycles of charge and discharge is 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com