Photocatalytic composite material and preparation method thereof

A composite material and photocatalysis technology, which is applied in the field of photocatalytic composite materials and preparation, can solve the problems of low catalytic efficiency of photocatalytic materials, achieve the effects of large specific surface area, simple preparation, and enhanced absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

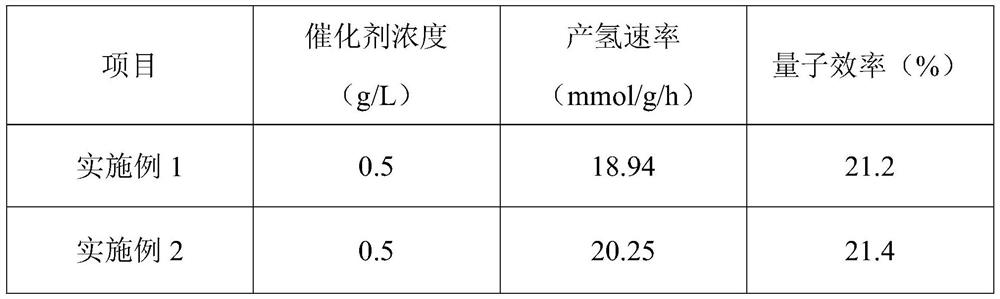

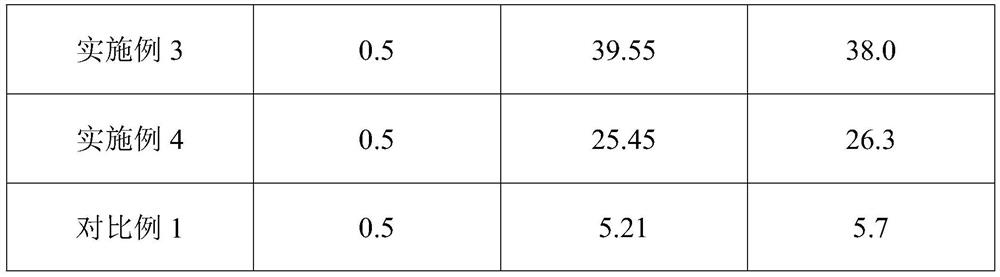

Embodiment 1

[0024] A method of preparing a photocatalytic composite, comprising the steps of:

[0025] S1: 0.233 g of zirconium chloride and 0.181 g 2-amino group terephthalic acid were added to 50 ml of DMF solution, and mixed mixed with mixed liquid, then transferred to the polytetrafluoroethylene reaction kettle, performed at 120 ° C After 48 h, after the reaction is completed, the reaction product is centrifted, washed, dried to give a three-dimensional MOF material UIO-66-NH. 2 ;

[0026] S2: 0.133 g of cadmium acetate and 0.439 g of zinc acetate, stirred evenly, and then 0.03 g of UIO-66-NH prepared by step S12 To the solution was added the above-described ultrasound for half an hour, stir, and then added dropwise 10mL0.3mol / L sodium sulfide solution, stirred and mixed uniformly to obtain a mixture, and then transferred the mixture to a Teflon autoclave, at 160 ℃ hydrothermal reaction 4h, after the completion of the reaction, the reaction product was centrifuged, washed, and dried, to...

Embodiment 2

[0029] A method of preparing a photocatalytic composite, comprising the steps of:

[0030] S1: zirconium chloride was added 0.233g and 0.181g 2- 50mL DMF solution to the amino terephthalic acid, uniformly stirred and mixed to obtain a mixture, and then transferred the mixture to a Teflon autoclave, subjected to hydrothermal 120 ℃ thermal reaction 48h, after the completion of the reaction, the reaction product was centrifuged, washed, and dried, to obtain a three-dimensional MOF material UiO-66-NH 2 ;

[0031] S2: 30mL of ethylene glycol was added to the solution 0.133g 0.439g zinc acetate and cadmium acetate, stirred uniformly, and then the step S1 is prepared 0.06g UiO-66-NH 2 To the solution was added the above-described ultrasound for half an hour, stir, and then added dropwise 10mL0.3mol / L sodium sulfide solution, stirred and mixed evenly to give mixture was then transferred to a teflon reaction vessel mixture was carried out at 160 ℃ hydrothermal reaction 4h, after the comp...

Embodiment 3

[0034] A method of preparing a photocatalytic composite, comprising the steps of:

[0035] S1: zirconium chloride was added 0.233g and 0.181g 2- 50mL DMF solution to the amino terephthalic acid, uniformly stirred and mixed to obtain a mixture, and then transferred the mixture to a Teflon autoclave, subjected to hydrothermal 120 ℃ thermal reaction 48h, after the completion of the reaction by centrifugation, washed, and dried, to obtain a three-dimensional MOF material UiO-66-NH 2 ;

[0036] S2: 30mL of ethylene glycol was added to the solution 0.133g 0.439g zinc acetate and cadmium acetate, stirred uniformly, and then the step S1 is prepared 0.09g UiO-66-NH 2 To the solution was added the above-described ultrasound for half an hour, stir, and then added dropwise 10mL0.3mol / L sodium sulfide solution, stirred and mixed evenly to give mixture was then transferred to a teflon reaction vessel mixture was carried out at 160 ℃ hydrothermal reaction 4h, after the completion of the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com