Hollow metal nitride/carbon microsphere composite material and preparation method and application thereof

A composite material and nitride technology, which is applied in the field of hollow metal nitride/carbon microsphere composite materials and its preparation, can solve the problems of large pore size of polyolefin diaphragm, sulfur volume expansion of lithium dendrites, and inability to suppress the shuttle effect. Achieve the effects of fast response, easy industrialization, and inhibition of shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a hollow metal nitride / carbon microsphere composite material, comprising the following steps:

[0040] S1: Precursor preparation:

[0041] S11: mixing organic molecules containing amino groups, metal carbonyl compounds and organic solvents;

[0042] S12: Under the protection of inert gas, ultrasonic reaction;

[0043] S13: washing and drying to obtain the precursor;

[0044] S2: spray drying:

[0045] S21: Stir and melt the obtained precursor and phenol, then add water and formaldehyde solution;

[0046] S22: continue to stir and add NaOH to adjust the pH;

[0047] S23: adding ethanol and silicon dioxide nano-dispersion liquid, stirring evenly, spray drying, and collecting the obtained powder material;

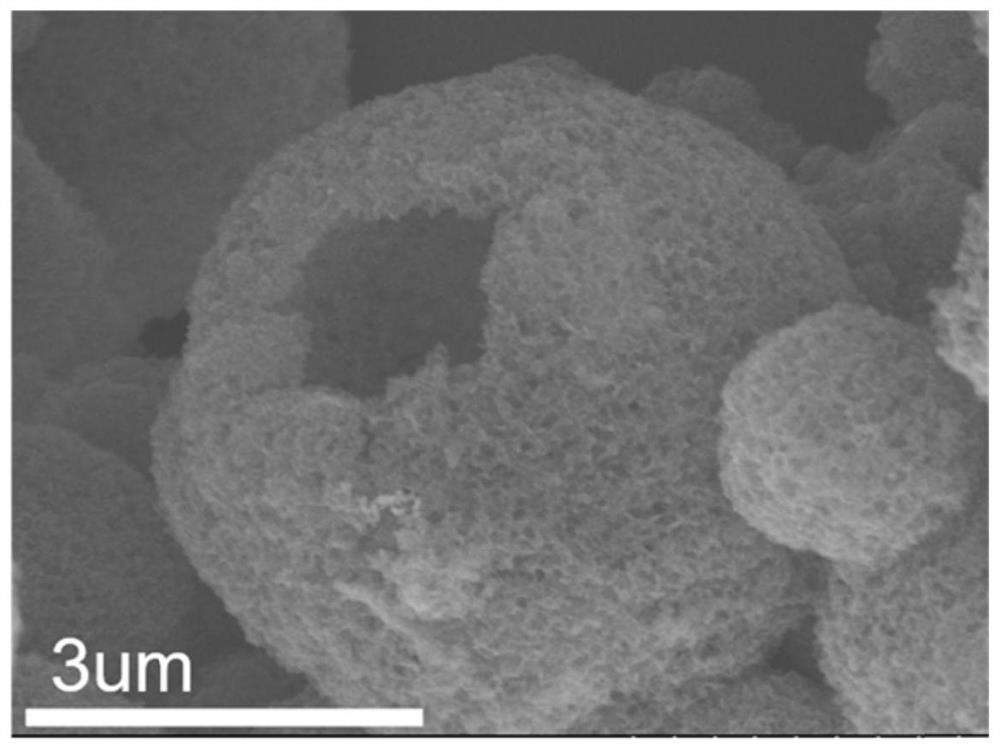

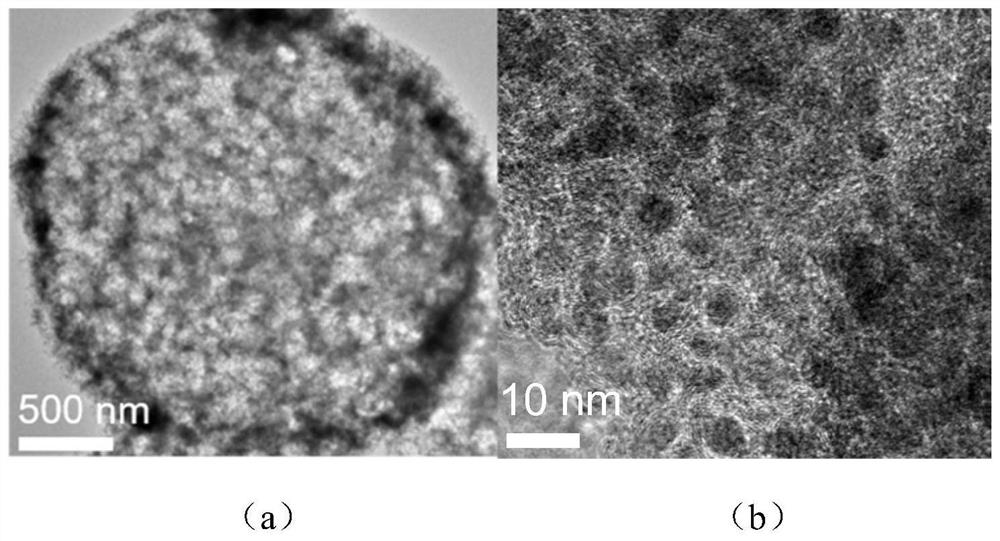

[0048] S3: Calcining the obtained powder material under an inert gas atmosphere, collecting the material after natural cooling, etching the material with an aqueous sodium hydroxide solution, washing and drying to obtain the hollow metal nitr...

Embodiment 1

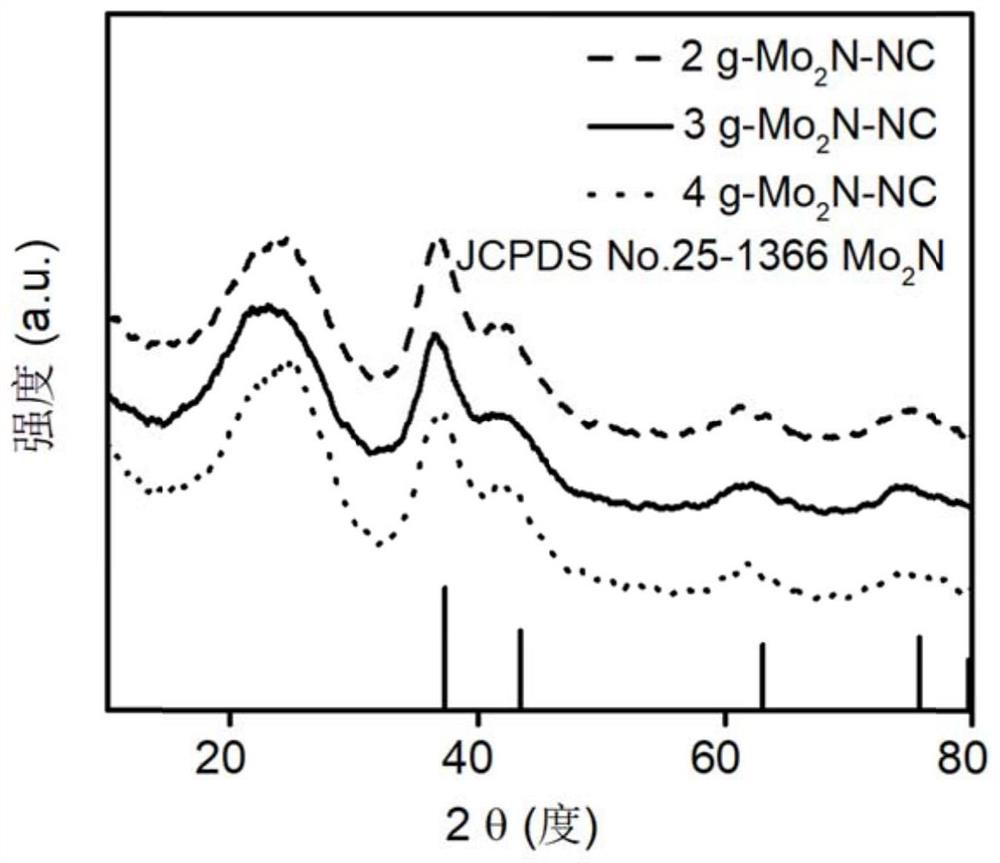

[0069] Add 5g of melamine, 2g of molybdenum carbonyl and 40mL of n-hexadecane into the flask and stir; then ultrasonically react at 80°C for 4h under argon; wash with n-pentane for 4 to 5 times, and bake at 105°C for 12h to obtain the precursor; Precursor The precursor and 2.5g of phenol were stirred and melted at 40°C. Add 20mL water and 20mL formaldehyde solution, then add 1M sodium hydroxide solution to adjust the pH=9, continue stirring for 1h, then add 35mL ethanol and 15g 20wt% SiO 2 / EtOH silica dispersion liquid with a size of 10nm, stirred for 15min, and spray-dried at 200°C to obtain the material; the obtained material was calcined at high temperature under an argon atmosphere with a heating rate of 10°Cmin -1 , roasted at 500°C for 5 hours, roasted at 900°C for 2 hours, and the material obtained after natural cooling was etched with 5M sodium hydroxide solution for 3 to 4 times, then washed with deionized water for 3 to 4 times, and finally air-dried at 80°C for 12 ...

Embodiment 2

[0071] Add 5g of melamine, 3g of molybdenum carbonyl and 40mL of n-hexadecane into the flask and stir; then ultrasonically react at 80°C for 4h under argon; wash with n-pentane for 4 to 5 times, and dry at 105°C for 12h to obtain the precursor; Precursor The precursor and 2.5g of phenol were stirred and melted at 40°C. Add 20mL water and 20mL formaldehyde solution, then add 1M sodium hydroxide solution to adjust the pH=9, continue stirring for 1h, then add 35mL ethanol and 15g 20wt% SiO 2 / EtOH silica dispersion liquid with a size of 10nm, stirred for 15min, and spray-dried at 200°C to obtain the material; the obtained material was calcined at high temperature under an argon atmosphere with a heating rate of 10°Cmin -1 , roasted at 500°C for 5 hours, roasted at 900°C for 2 hours, and the material obtained after natural cooling was etched with 5M sodium hydroxide solution for 3 to 4 times, then washed with deionized water for 3 to 4 times, and finally air-dried at 80°C for 12 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com