Preparation method of polybenzimidazole polymer with high molecular weight and high solubility

A technology of polybenzimidazoles and polymers, which is applied in the field of preparation of polybenzimidazoles polymers, can solve the troublesome processing technology, the solubility problem of polybenzimidazoles polymers is not well solved, and affects the material Performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

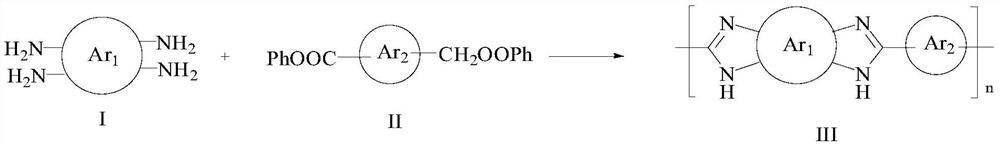

[0056] The present invention provides a kind of preparation method of polybenzimidazole polymer of high molecular weight and high solubility, specifically, the method of the present invention comprises: use tetramine compound A and dicarboxylate phenyl ester compound B, in catalyst C and In the presence of arylphenol D, polybenzimidazole polymers are prepared by two-step high-temperature condensation under the protection of nitrogen flow.

[0057] Wherein, the molar ratio of tetramine compound A to phenyl dicarboxylate compound B is 1:0.6-1.5 (preferably 1:1); the amount of catalyst C is the total mass of tetramine compound A and phenyl dicarboxylate compound B 0.01%-5%; the amount of arylphenol D is 1%-500% of the total mass of tetraamine compound A and dicarboxylate phenyl compound B.

[0058] In the stepwise polymerization, the reaction temperature of the first step is 180°C-300°C, and the reaction temperature of the second step is 240°C-450°C.

[0059] In a preferred embo...

Embodiment 1

[0085] Preparation of m-PBI:

[0086]

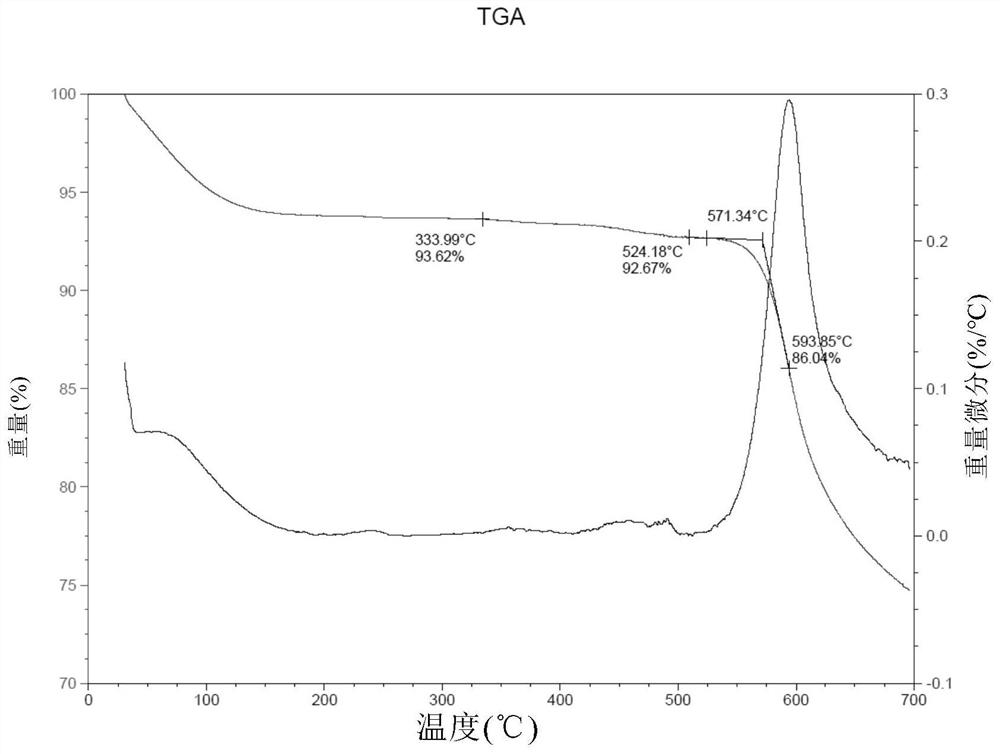

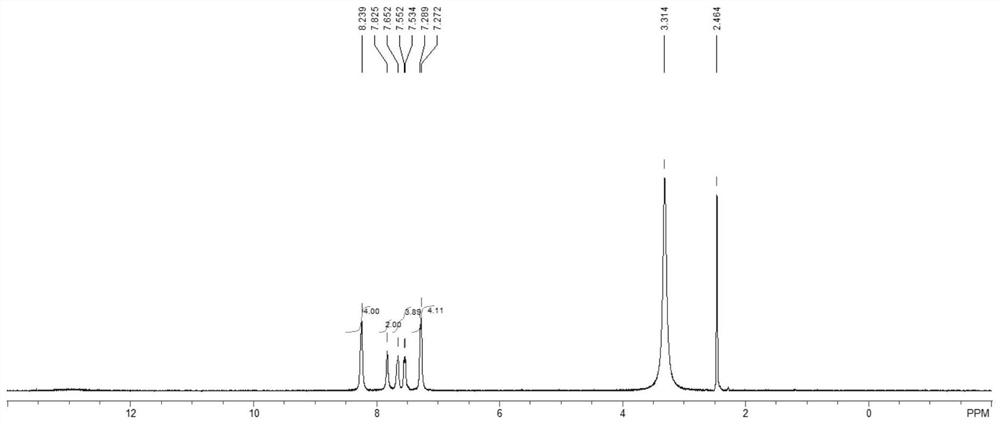

[0087] Add biphenyltetramine (21.43g, 100mmol), diphenyl isophthalate (31.83g, 100mmol), triphenyl phosphite (53.3mg), phenol (26.63g) then vacuumize, change nitrogen, repeat operation three times. Start heating, and start stirring when the solid turns into a solution state. At the same time, turn on the nitrogen flow (flow rate is 500mL / min), heat to 270°C for reaction, and when the viscosity of the system is very high (stirring is difficult), stop stirring and continue the reaction for 2 hours. , stop responding. After cooling to room temperature, the obtained solid prepolymer was pulverized into a fine powder. Add the pulverized prepolymer fine powder into the reaction kettle again, then evacuate, change nitrogen, and repeat the operation three times. Under the protection of nitrogen flow (flow rate of 500 mL / min), heating was started, heated to 380° C. for 2 hours to obtain m-PBI. The polymer’s Mw=243265, molecular weight dist...

Embodiment 2

[0089] Preparation of m-PBI:

[0090]

[0091] Add biphenyltetramine (21.43g, 100mmol), diphenyl isophthalate (31.83g, 100mmol), diphenyl phosphite (266.3mg), o- Cresol (53.26g) is then vacuumized, and nitrogen is changed, and the operation is repeated three times. Start heating, and start stirring when the solid turns into a solution state. At the same time, turn on the nitrogen flow (flow rate is 250mL / min), and heat to 260°C for reaction. When the viscosity of the system is very high (stirring is difficult), stop stirring and continue the reaction for 1.5 hours. , stop responding. After cooling to room temperature, the obtained solid prepolymer was pulverized into a fine powder. Add the pulverized prepolymer fine powder into the reaction kettle again, then evacuate, change nitrogen, and repeat the operation three times. Under the protection of nitrogen flow (flow rate of 250 mL / min), heating was started, heated to 360° C. and reacted for 2 hours to obtain m-PBI. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com