A fluorescent blotting membrane for in situ visual detection of root exudates and its preparation and application

A technology of root exudates and imprinted membranes, which is applied in the field of fluorescent imprinted membranes, can solve problems such as root damage, inconvenient assembly, and cumbersome steps, and achieve the effects of wide application, simple operation, and high specific response value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

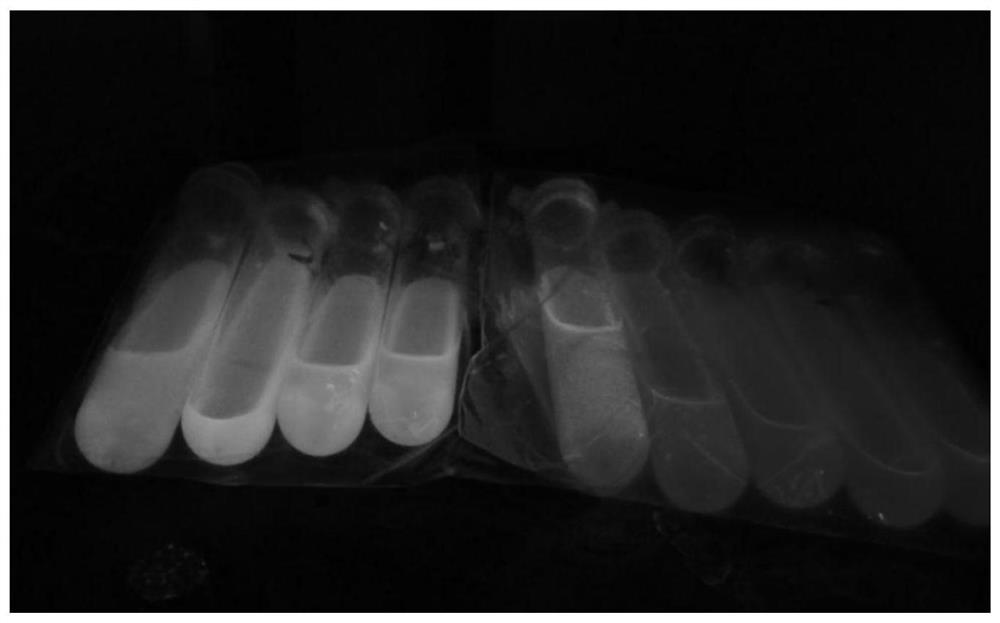

[0062] (1) Preparation of CdTe quantum dots

[0063] 1.6g of sodium borohydride and 1.6g of tellurium powder were mixed uniformly, then dispersed in 100mL of distilled water, and reacted in the dark for 6h at room temperature to obtain NaHTe solution, the precursor of Te in CdTe quantum dots. Dissolve 0.4 g of cadmium chloride and 0.5 mL of thioglycolic acid (TGA) in 50 mL of distilled water, add a 5% NaOH solution to adjust the pH to 10, and after 0.5 h of nitrogen deoxygenation, 25 mL of the precursor NaHTe solution is added to the solution. In the mixed solution, the mixed solution was heated to 90 °C in a water bath for reflux reaction for 3 h to obtain a CdTe QDs solution, washed three times with absolute ethanol, centrifuged and freeze-dried for 12 h to obtain CdTe QDs powder.

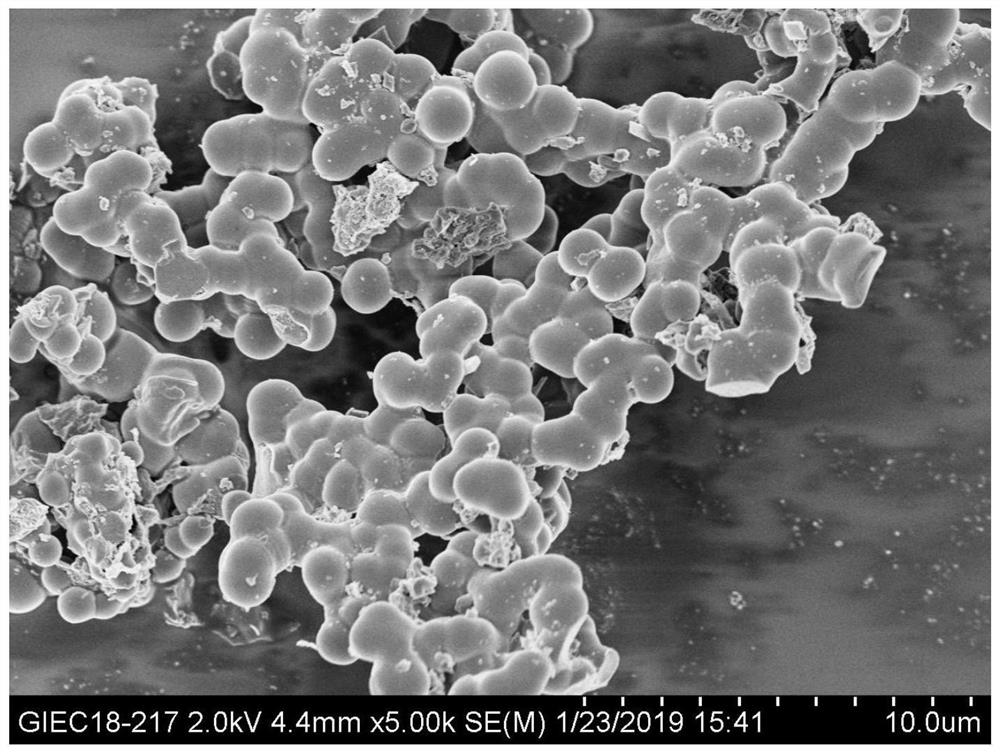

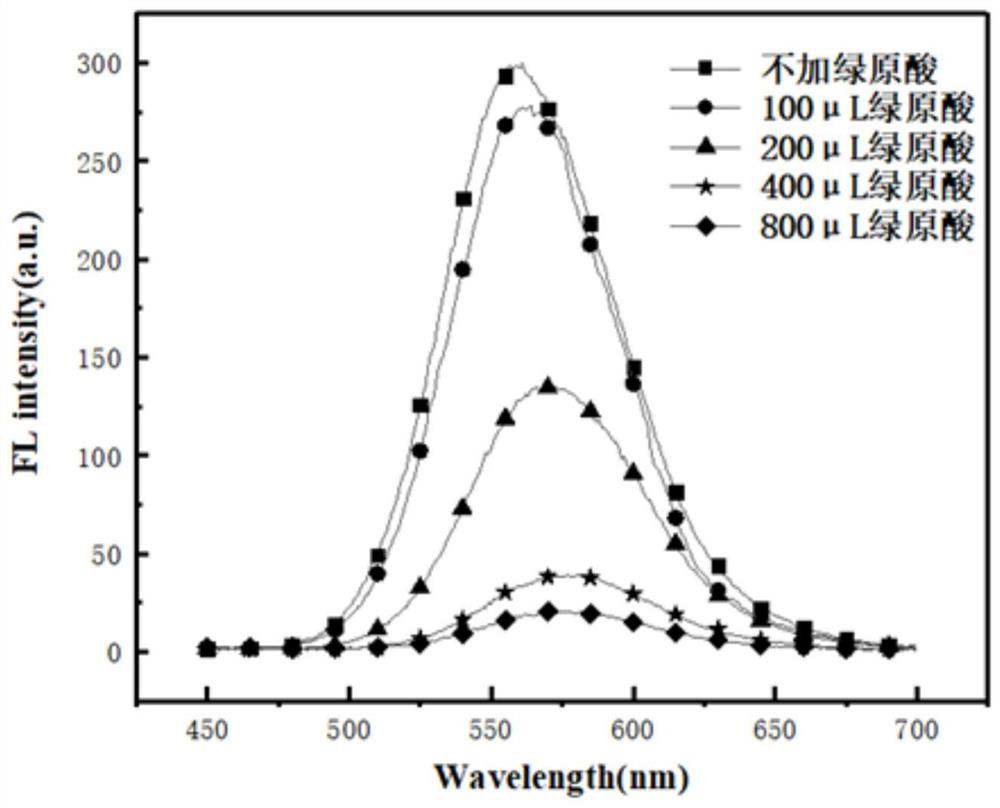

[0064] (2) CdTe@SiO 2 Preparation of @MIPs Molecularly Imprinted Polymers

[0065] Preparation of CdTe@SiO by Inverse Microemulsion Method 2 @MIPs: Add 100 mL of cyclohexane, 10 mL of NP-10, a...

Embodiment 2

[0069] (1) Preparation of CdTe quantum dots

[0070] 1.6 g of sodium borohydride (NaBH 4 ) and 3.2 g of tellurium powder were mixed evenly, then dispersed in 100 mL of distilled water, and reacted in the dark for 6 h at room temperature to obtain NaHTe solution, the precursor of Te in CdTe quantum dots. Dissolve 0.5 g of cadmium chloride and 0.5 mL of thioglycolic acid (TGA) in 50 mL of distilled water, add a 5% NaOH solution to adjust the pH to 10, and after 0.5 h of nitrogen deoxygenation, 17 mL of the precursor NaHTe solution was added to the solution. In the mixed solution, the mixed solution was heated to 120 °C in a water bath for reflux reaction for 3 h to obtain a CdTe QDs solution, washed three times with absolute ethanol, centrifuged and freeze-dried for 12 h to obtain CdTe QDs powder.

[0071] (2) CdTe@SiO 2 Preparation of @MIPs Molecularly Imprinted Polymers

[0072] Preparation of CdTe@SiO by Inverse Microemulsion Method 2 @MIPs: Add 100 mL of cyclohexane, 14 ...

Embodiment 3

[0076] (1) Preparation of CdTe quantum dots

[0077] 3 g of sodium borohydride (NaBH 4 ) and 3 g of tellurium powder were mixed evenly, then dispersed in 100 mL of distilled water, and reacted in the dark for 12 h at room temperature to obtain NaHTe solution, the precursor of Te in CdTe quantum dots. 0.5 g of cadmium chloride (CdCl 2) and 1.5 mL of thioglycolic acid (TGA) were dissolved in 50 mL of distilled water, and a 5% NaOH solution was added to adjust the pH to 10. After 0.5 h of nitrogen deaeration, 75 mL of the precursor NaHTe solution was added to the mixed solution, The mixed solution was heated to 90°C in a water bath for reflux reaction for 9h to obtain a CdTe QDs solution, washed with absolute ethanol for 3 times, centrifuged and freeze-dried for 12h to obtain CdTe quantum dot powder.

[0078] (2) CdTe@SiO 2 Preparation of @MIPs Molecularly Imprinted Polymers

[0079] Preparation of CdTe@SiO by Inverse Microemulsion Method 2 @MIPs: Add 100 mL of cyclohexane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com