Environment-friendly device for preparing heavy water and overweight water mixed liquid by evaporating light water and structure thereof

A technology of super-heavy water and mixed liquid, which is applied in the direction of heating water/sewage treatment, etc., can solve the problems of increasing super-heavy water, complicated process, high production cost, etc., and achieve the effect of mitigating global warming, simple equipment structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

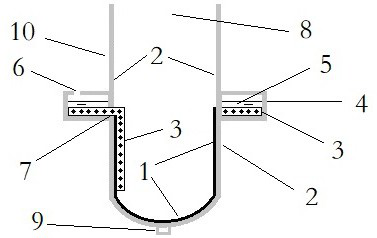

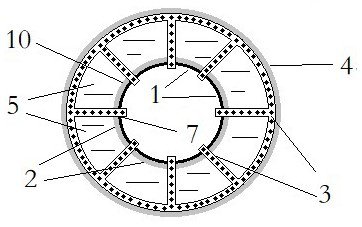

[0053] This embodiment provides an open type evaporative separator, such as Figure 1-3 As shown, it includes evaporation layer 1, waterproof layer 2, water guide strip 3, water storage 4, water 5, water injection port 6, water outlet 7, ventilation port 8, water outlet pipe 9, evaporator 10; the waterproof layer 2 It is a sheet-shaped waterproof material with a thickness of 0.1mm-100mm (such as plastic, metal, etc., as long as it can not be soaked by the water 5); the waterproof layer is made with a height of 200mm-10000mm and a cross-section with a diameter of 20mm- 1000mm, a cylindrical hollow container with a hemispherical structure at the bottom and an opening at the top (that is, the vent 8), that is, the evaporator 10; the evaporating layer 1 is natural fibers and / or chemical fibers with a thickness of 0.1mm-1mm and Its fabric (such as absorbent cotton yarn, absorbent paper towel, quick-drying imitation cotton cloth, etc., as long as it can be wetted by the water 5 and ...

no. 2 example

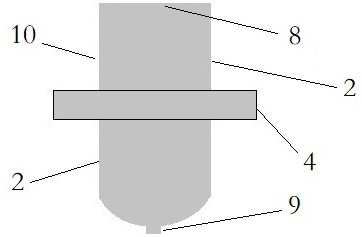

[0056] This embodiment provides a narrow mouth type evaporative separator, such as Figure 4-6As shown, it includes evaporation layer 1, waterproof layer 2, water reservoir 4, water 5, water injection port 6, water outlet 7, air vent 8, water outlet pipe 9, and evaporator 10; the specific composition, structure and work of this embodiment The principle is basically the same as that of the first embodiment, and the difference from the first embodiment is: first, the water guide bar 3 is not provided, and the evaporation layer 1 is used to replace the water guide bar 3 and the water storage 4 connections, that is, the upper end of the evaporation layer 1 is divided into multiple strips, passing through the waterproof layer 2, passing through the water outlet 7 one by one, and extending into the water storage 4, where The bottom of the water storage 4 is connected into an integrated structure through sewing and other techniques; the water 5 in the water storage 4 is realized to w...

no. 3 example

[0058] This embodiment provides combined evaporation separator, such as Figure 7-9 As shown, it includes evaporation layer 1, waterproof layer 2, water guide strip 3, water reservoir 4, water 5, water injection port 6, water outlet 7, air vent 8, water outlet pipe 9, evaporator 10, separation net 11, water pump 12, pumping pipeline 13, baffle plate 14, water storage tank 15; The specific composition, structure, working principle of this embodiment are basically the same as the first embodiment, and the differences with the first embodiment are: one is this embodiment It is a combination of two or more first embodiments, and at the same time, the device is only provided with one water storage 4, and through several water guide strips 3 respectively, each of the evaporators 10 in the The evaporation layer 1 transports the water 5, and at the same time, the water outlet pipe 9 at the bottom of each evaporator 10 is connected as a whole through a three-way joint; the second is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com