Production method and system of naphthol AS series products

A technology for a series of products and production methods, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid amides, etc., can solve the problems of energy consumption, high labor costs, production of AS series products, and large losses, etc. Achieve the effect of low production cost, reduced recycling difficulty, and improved market risk capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

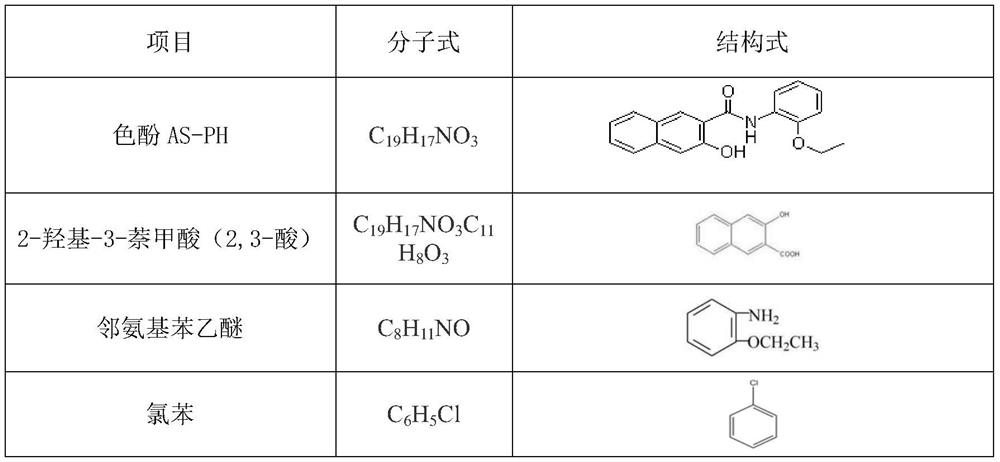

[0022] A process introduction of the process of producing phenol As-pH, by-product phosphate. Molecular formulas and structural formulas involving organic matter in production of chlorol AS-pH are shown in Table 1 below. Its raw material is 2-hydroxy-3-naphthoic acid, phosphoric acid, phosphorus, wherein trichloride is a condenser. Solvent uses chlorobenzene.

[0023] Table 1

[0024]

[0025] The chemical reaction involved is as follows:

[0026] 3C 11 Hide 8 O 3 + 3C 8 Hide 11 NO + 1PCL 3 → 3C 19 Hide 17 NO 3 + 1h 3 PO 3 + 3HCL ↑

[0027] 2h 3 PO 3 + 1NA 2 CO 3 → 2nah 2 PO 3 + 1h 2 O + 1CO 2 ↑

[0028] Nah 2 PO 3 + CAO → CAHPO 3 ↓ + naoh

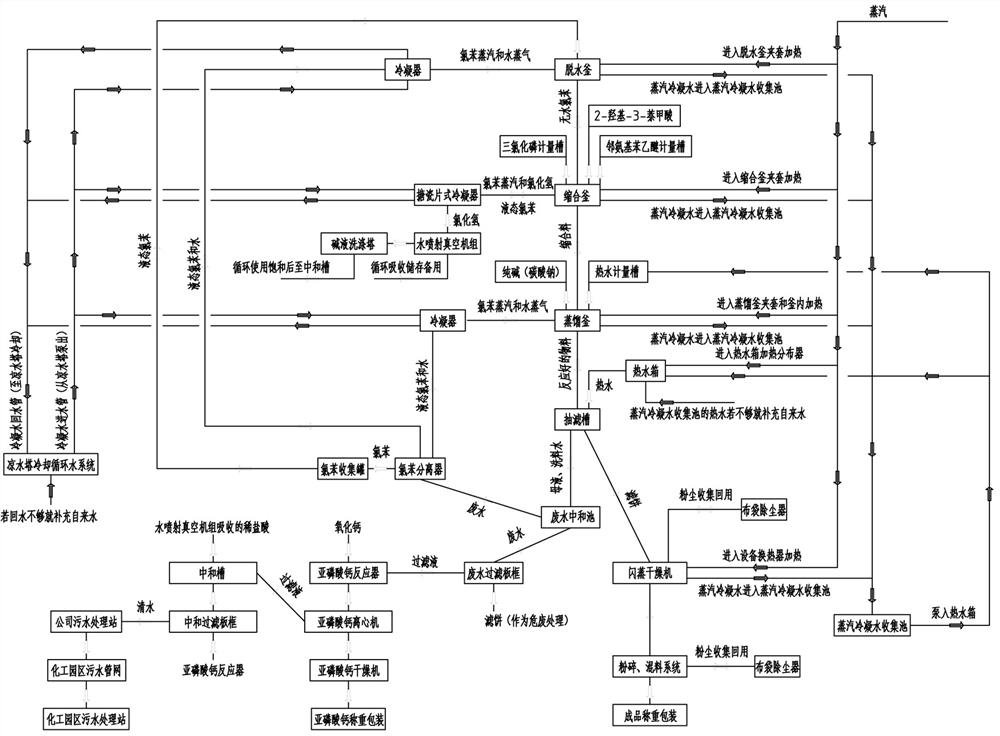

[0029] Specific production method is like figure 1 Down:

[0030] S1, solvent chlorobenzene, and phosphorus phosphorus, respectively, the corresponding tank is pumped into the corresponding metering tank, and the quantitative chlorobenzene is added to the dehydrate, and the stirring is opened, the jacket is passed through the steam, and the ...

Embodiment 2

[0038] Production method of tallol AS series, specifically producing phenol As-LC, including the following steps:

[0039] S1, the condensation reaction is solvent 5000 kg of chlorobenzene, adding a dehydrated extract, dehydrated temperature at 115-130 ° C, and the chlorobenzene steam condensation generated in dehydration, part of the chlorobenzene liquid and water into the chlorobenzene separator; then Raw material reactant 2-hydroxy-3-naphthoate 700 kg, 2,5-dimethoxy-4-chloroaniline 695 kg, heating to 60-70 ° C, heating heating to 60-70 ° C, add trichloride The condensation reaction, the phosphorus trichloride dripping 170 kg, the reaction temperature is 120-130 ° C, the reaction time is 3 hours; the resulting chlorobenzene steam during the condensation reaction is refluxed after condensation, and hydrogen chloride gas is absorbed by water injection vacuum unit. After the liquid reaches 30% by weight, the dilute hydrochloric acid is transferred;

[0040] S2, 1000 kg of sodium car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com