Novel bone glue modified asphalt and preparation method thereof

A technology of modified asphalt and bone glue, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor fatigue performance of modified asphalt, heavy burden of road construction, complicated preparation process, etc., to reduce the phase angle, improve the Low temperature crack resistance, simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

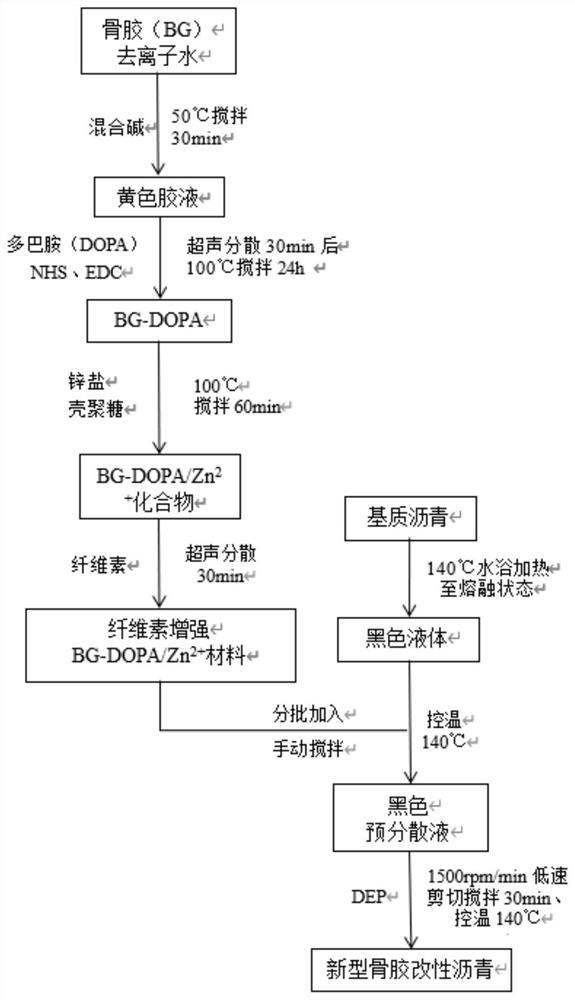

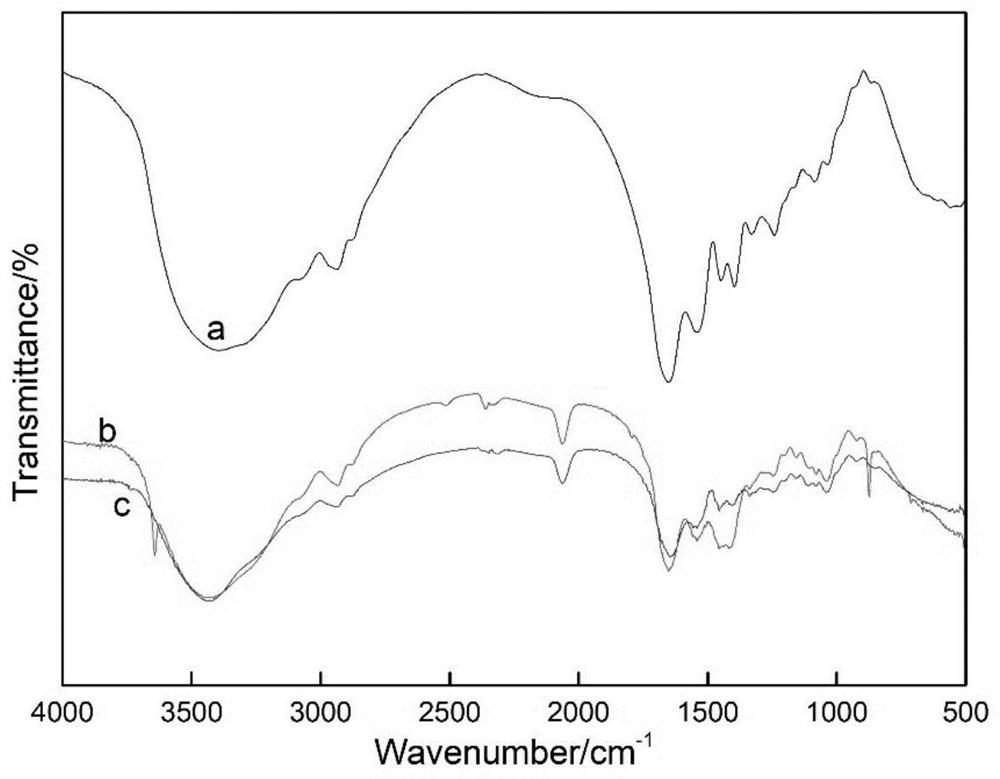

Method used

Image

Examples

Embodiment 1

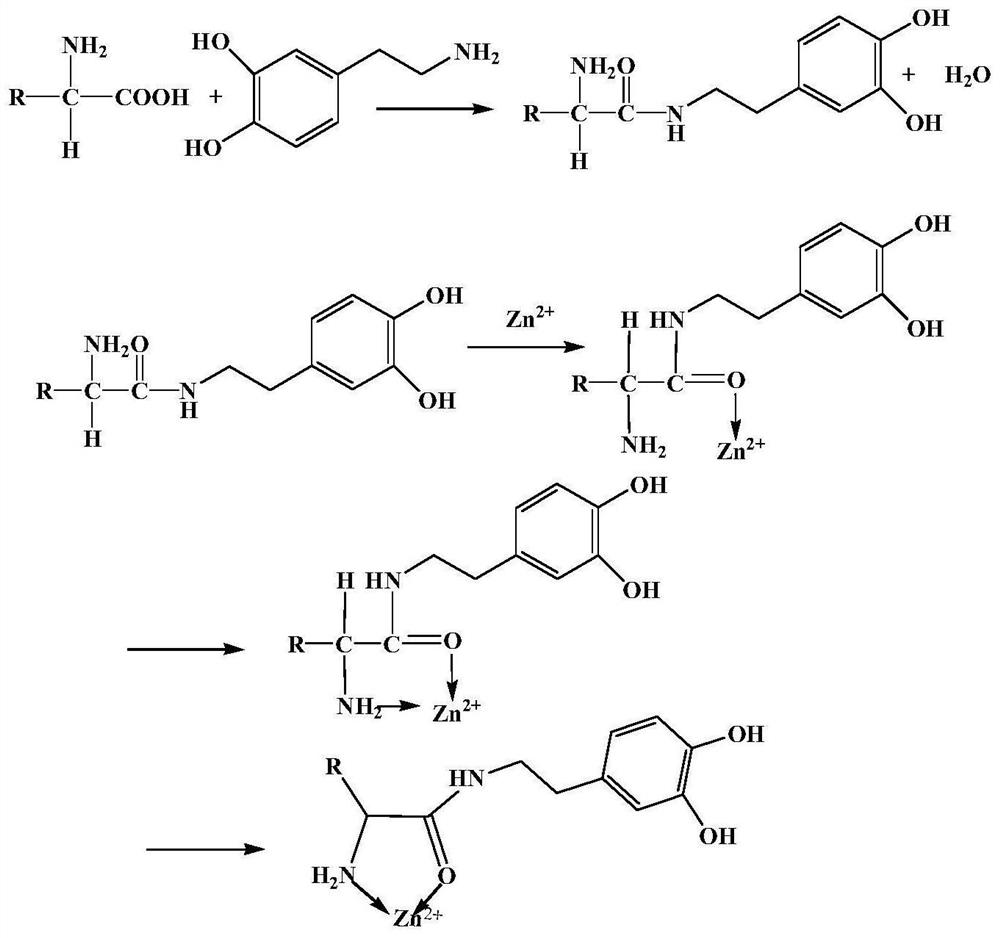

[0033] 1) Cellulose reinforced BG-DOPA / Zn 2+ Preparation of materials:

[0034] After fully mixing 80g of BG and 160g of deionized water, add 7g of mixed alkali (4gNaOH+3gNa 2 CO 3 ) and continue to stir for 30 minutes; then add 15gDOPA, 1.5gNHS, 2.0gEDC for ultrasonic dispersion for 30min, and put the mixture into a water bath at 100°C after uniform dispersion, and continue to stir for 24h; add 4.2g ZnCl to the mixture 2 and 6g chitosan, continue to stir in a water bath at 100°C for 60min to obtain BG-DOPA / Zn 2+ Compound; 10 g of cellulose was added to BG-DOPA / Zn 2+ Among the compounds, cellulose-enhanced BG-DOPA / Zn was prepared by ultrasonic dispersion 2+ Material.

[0035] 2) Preparation of Bone Glue Modified Asphalt

[0036] Weigh 150g International 70 # Put road petroleum asphalt in a water bath at 140°C, and add 10g of cellulose-reinforced BG-DOPA / Zn in batches when it is heated to a molten state 2+ The materials were manually stirred until no obvious air bubbles...

Embodiment 2

[0038] 1) Cellulose reinforced BG-DOPA / Zn 2+ Preparation of materials:

[0039]After fully mixing 100g BG and 220g deionized water, add 9g mixed alkali (4gKOH+5g K 2 CO 3 ) and continue to stir for 30 minutes; then add 18gDOPA, 1.5gNHS, 2.0gEDC for ultrasonic dispersion for 30min, put the mixture into a water bath at 100°C after uniform dispersion, and continue to stir for 24h; add 5.5gZnSO to the mixture 4 and 7.5g chitosan, continue to stir in a water bath at 100°C for 60min to obtain BG-DOPA / Zn 2+ Compound; 18 g of cellulose was added to BG-DOPA / Zn 2+ Among the compounds, cellulose-enhanced BG-DOPA / Zn was prepared by ultrasonic dispersion 2+ Material.

[0040] 2) Preparation of Bone Glue Modified Asphalt

[0041] Weigh 150g International 70 # Put road petroleum asphalt in a 140°C water bath, and add 8.5g of cellulose-reinforced BG-DOPA / Zn in batches when it is heated to a molten state 2+ The materials were manually stirred until no obvious air bubbles were generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com