Degradable polyurethane biological material as well as preparation method and application thereof

A biomaterial and polyurethane technology, applied in the field of degradable polyurethane biomaterials and its preparation, can solve the problems of secondary cracking of wounds, affecting patient recovery, and reduced mechanical strength, and achieve simple process, excellent mechanical properties and degradation performance, and good Effect of mechanical properties and degradation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

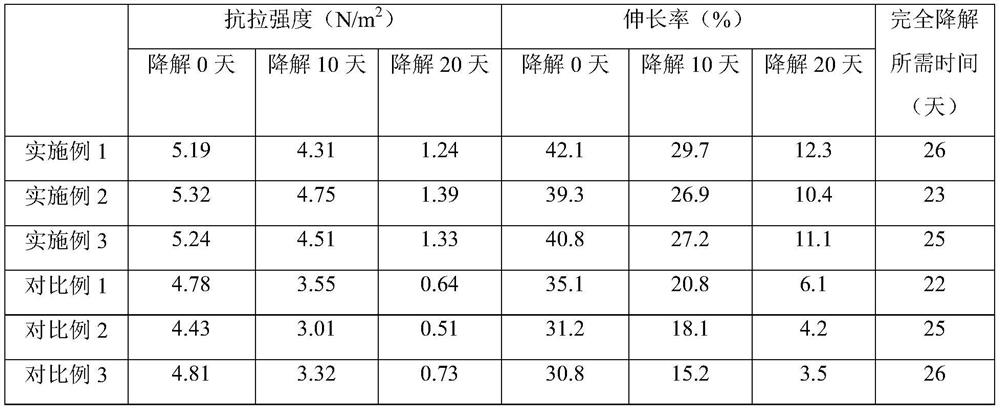

Examples

Embodiment 1

[0033] A method for preparing a degradable polyurethane biomaterial, comprising coaxial electrospinning the first solution and the second solution to obtain the polyurethane biomaterial; wherein, the preparation method of the first solution is as follows:

[0034] (A) First add lysine monomer and p-nitrophenyl adipate monomer into N,N-dimethylacetamide, stir and mix well, stir and react at 65°C for 40 minutes, then add nano calamine powder , continue to insulate and stir the reaction, and post-process to obtain nanoparticles;

[0035] (B) then add casein and acrylic acid to water, stir and mix well, under the condition of nitrogen protection, add potassium persulfate, stir and react, add the nanoparticles obtained in step (A), electron beam irradiation, post-treatment, and make the modified Nanoparticles;

[0036] (C) Finally, adding polyether glycol, modified nanoparticles, and dibutyltin dilauric acid into N,N-dimethylacetamide, and ultrasonically oscillating evenly to obta...

Embodiment 2

[0051] A method for preparing a degradable polyurethane biomaterial, comprising coaxial electrospinning the first solution and the second solution to obtain the polyurethane biomaterial; wherein, the preparation method of the first solution is as follows:

[0052] (A) First add lysine monomer and p-nitrophenyl adipate monomer into N,N-dimethylacetamide, stir and mix well, stir and react at 75°C for 30 minutes, then add nano calamine powder , continue to insulate and stir the reaction, and post-process to obtain nanoparticles;

[0053] (B) then add casein and acrylic acid to water, stir and mix well, under the condition of nitrogen protection, add potassium persulfate, stir and react, add the nanoparticles obtained in step (A), electron beam irradiation, post-treatment, and make the modified Nanoparticles;

[0054] (C) Finally, adding polyether glycol, modified nanoparticles, and dibutyltin dilauric acid into N,N-dimethylacetamide, and ultrasonically oscillating evenly to obta...

Embodiment 3

[0069] A method for preparing a degradable polyurethane biomaterial, comprising coaxial electrospinning the first solution and the second solution to obtain the polyurethane biomaterial; wherein, the preparation method of the first solution is as follows:

[0070] (A) First add lysine monomer and p-nitrophenyl adipate monomer into N,N-dimethylacetamide, stir and mix well, stir and react at 70°C for 35 minutes, then add nano calamine powder , continue to insulate and stir the reaction, and post-process to obtain nanoparticles;

[0071] (B) then add casein and acrylic acid to water, stir and mix well, under the condition of nitrogen protection, add potassium persulfate, stir and react, add the nanoparticles obtained in step (A), electron beam irradiation, post-treatment, and make the modified Nanoparticles;

[0072] (C) Finally, adding polyether glycol, modified nanoparticles, and dibutyltin dilauric acid into N,N-dimethylacetamide, and ultrasonically oscillating evenly to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com