Copper/porous carbon catalyst and preparation method and application thereof

A technology of porous carbon and catalyst, applied in the field of copper/porous carbon catalyst and its preparation, can solve the problems of low specific surface area, reduced catalyst stability, reduced active sites, etc., to achieve high specific surface area, reduce internal diffusion resistance, Increase the effect of active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of a copper / porous carbon catalyst, comprising the following steps:

[0027] (1) After mixing copper precursor, auxiliary agent, biomass-based porous carbon and water, aging and drying are performed in turn to obtain a precursor;

[0028] (2) calcining the precursor obtained in the step (1) to obtain a calcined body;

[0029] (3) reducing the calcined body obtained in the step (2) to obtain a copper / porous carbon catalyst.

[0030] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in the field.

[0031] In the present invention, unless otherwise specified, all operations performed are at room temperature.

[0032] In the present invention, after mixing copper precursor, auxiliary agent, biomass-based porous carbon and water, aging and drying are performed in turn to obtain the precursor.

[0033] In the present invention, the material ratio of the c...

Embodiment 1

[0067] 1. Preparation method of biomass-based porous carbon:

[0068] 1) washing 17.3565g of pine wood chips in turn, drying at 105° C. for 24h, and pulverizing to obtain 11.6357g of pretreated pine wood chips;

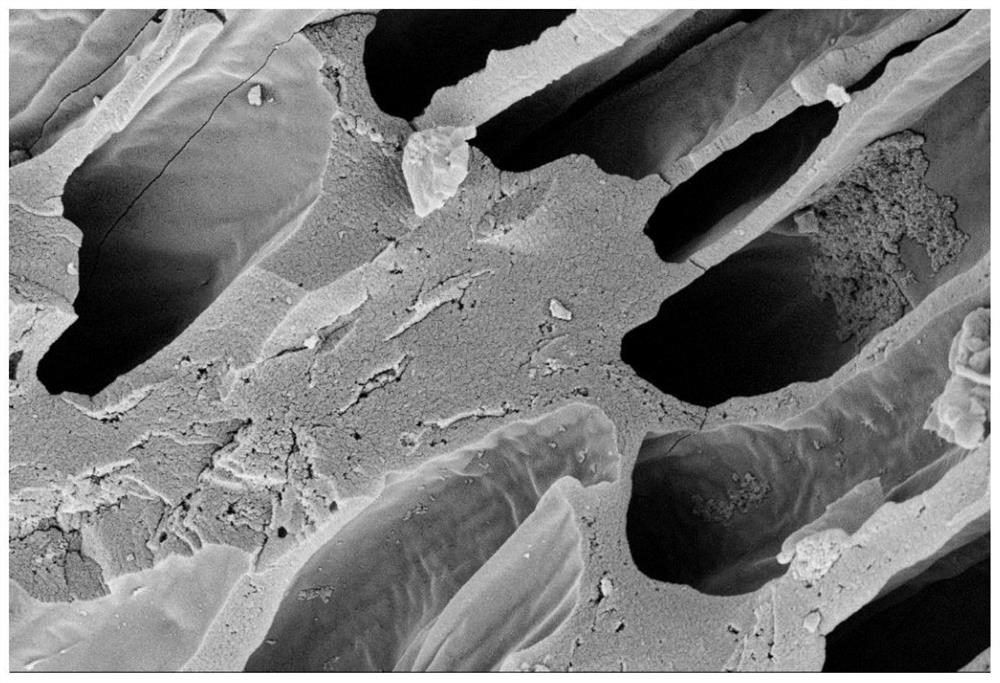

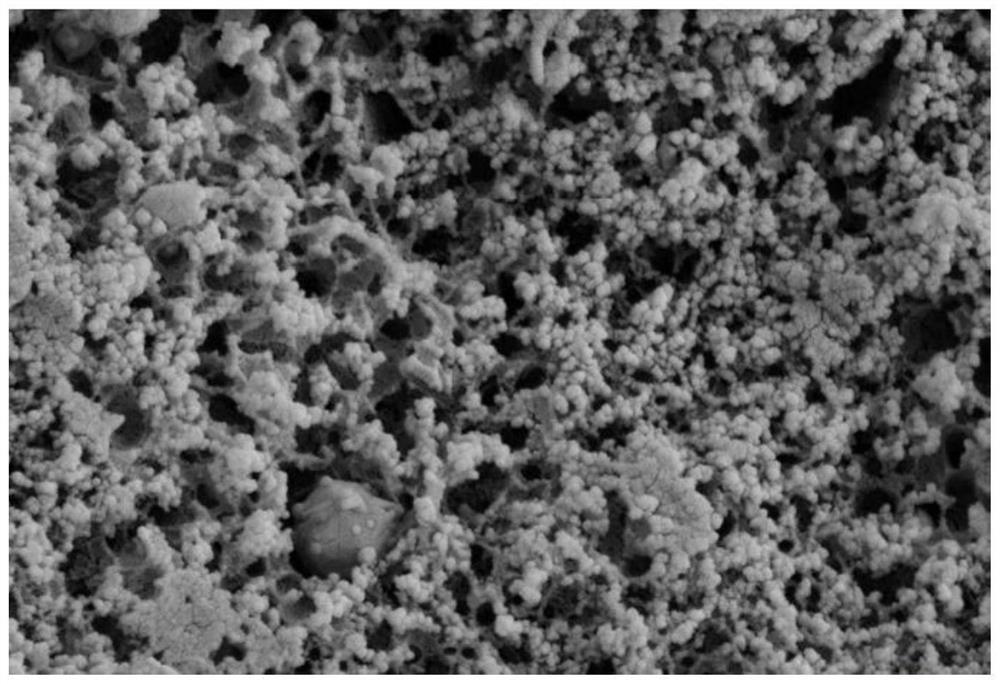

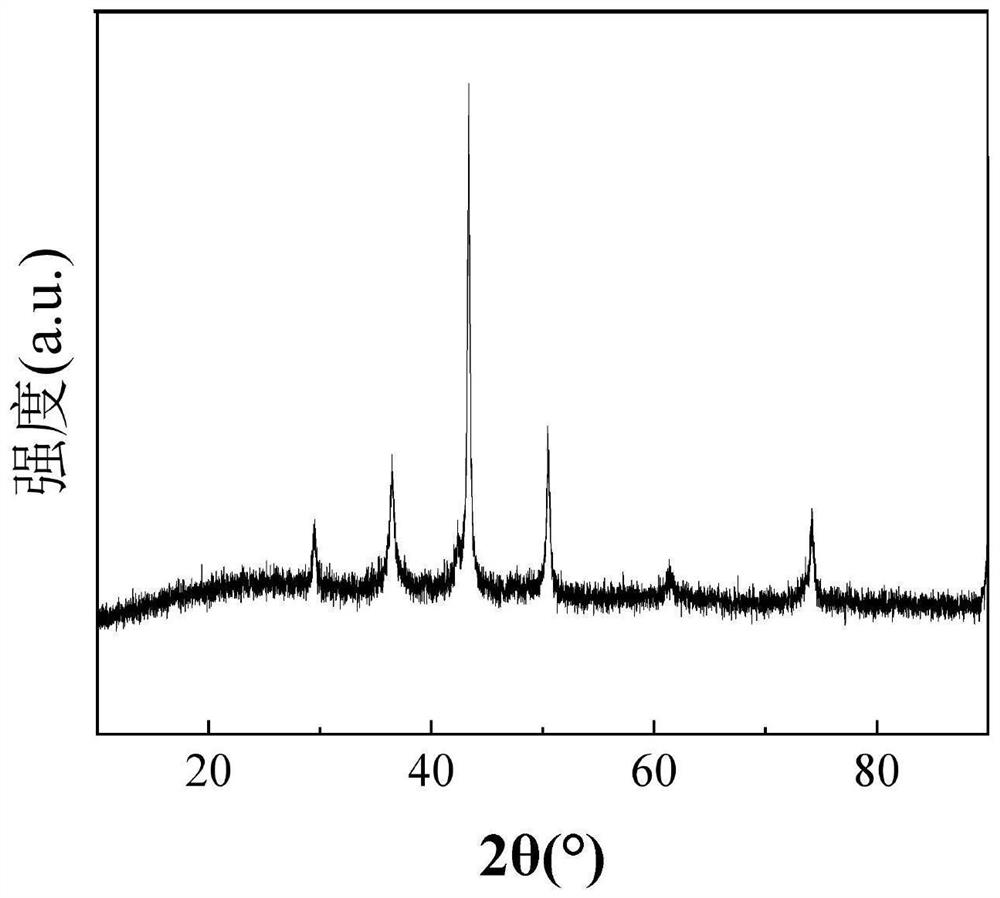

[0069] 2) 10.9656g of pretreated pine wood chips obtained in step 1) and 13.0486gH 3 PO 4 The mixture was mixed in a mass ratio of 1:1.2, immersed in a water bath at 80°C for 12 hours, then placed in an atmospheric muffle furnace in a nitrogen atmosphere for activation at 500°C for 90min, and then added 10wt% hydrochloric acid and placed in a water bath at 80°C for magnetic stirring. Washed for 30min, then washed with deionized water until neutral, and dried to obtain 9.8942g biomass-based porous carbon material. The specific surface area of the material was analyzed by the BET method, and the pore volume of the material was analyzed by the BJH method. Analysis was carried out, and the specific surface area of the prepared biomass-based porous carbon material wa...

Embodiment 2

[0080] According to the method of Example 1, biomass-based porous carbon materials and copper / porous carbon catalysts were prepared, and the prepared copper / porous carbon catalysts were applied to methanol hydrogen production by the same method.

[0081] Among them, in the process of preparing biomass-based porous carbon materials, 20.6895g sycamore wood chips were used as biomass materials, and 20.6895g pine wood chips and 24.6582g activator H were pretreated. 3 PO 4 The mass ratio of 1:1.2; the impregnation temperature is 60°C, and the impregnation time is 12h; the activation temperature is 400°C, and the activation time is 1.2h; the acid used for the pickling is 15wt% hydrochloric acid; The specific surface area of the prepared biomass-based porous carbon material measured by the same method in Example 1 is 687m 2 ·g -1 , the hole volume is 0.826cm 3 ·g -1 , with an average pore size of 4.811 nm;

[0082] In the process of preparing copper / porous carbon catalyst, 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com