Biomass-based environment-friendly washable flame retardant PD flame-retardant finished fabric and preparation method thereof

A technology of flame retardant finishing and flame retardant, applied in the preparation of organic compounds, flame retardant fibers, chemical instruments and methods, etc., can solve the problems of non-washable flame retardant effect, release harmful gas, etc., and achieve fabric whiteness And the effect of small breaking strength, mild conditions and good char formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

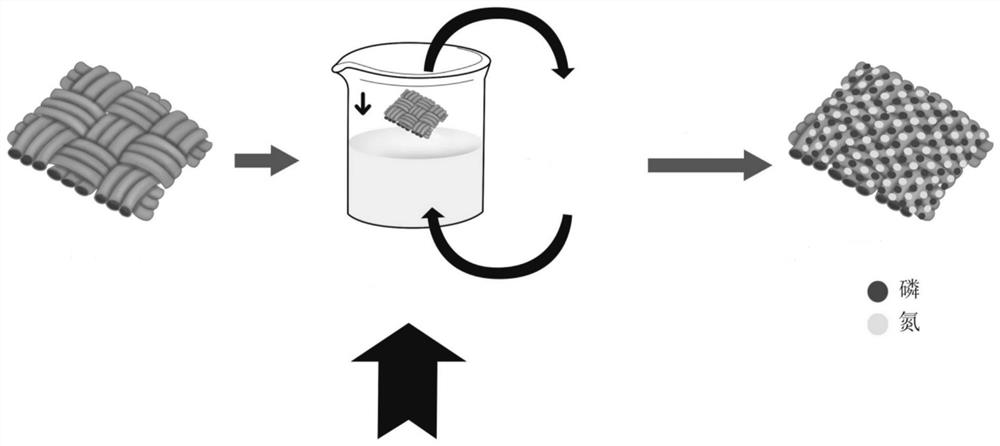

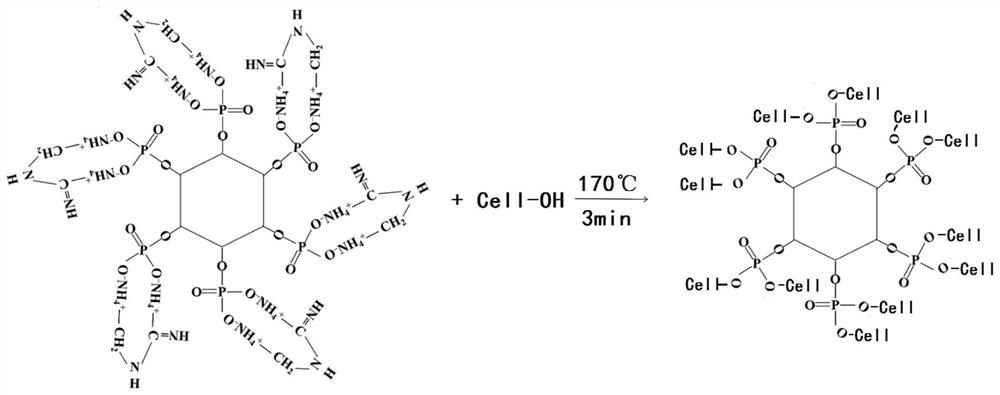

[0037] see Figure 1-10 , the present invention provides a technical solution:

[0038] A preparation method of a biomass-based environmentally friendly flame retardant PD agent flame-retardant finishing fabric, the specific steps of the preparation method of the biomass-based environmentally friendly flame retardant PD are as follows:

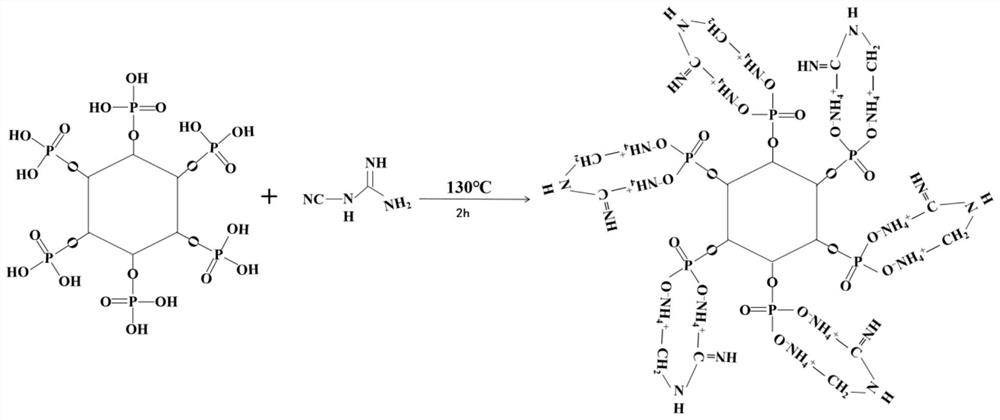

[0039] S1: Add 0.1 mol of phytic acid aqueous solution and 0.6 mol of dicyandiamide to a 250 ml three-necked flask in sequence to obtain a mixed reaction solution;

[0040] S2: heating the mixed reaction liquid obtained in step S1 to 130° C. under magnetic stirring, condensing and refluxing for 2 hours to obtain a light yellow transparent viscous crude product liquid;

[0041] S3: Precipitate the crude product liquid in step S2 with absolute ethanol and acetone, suction filter, wash, remove unreacted reactants, and dry with a freeze dryer at -50°C and 8pa to obtain a white solid flame retardant PD .

[0042] A biomass-based environmentally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com