Nanogold enrichment tube and preparation method thereof, and device and method for sampling mercury in flue gas

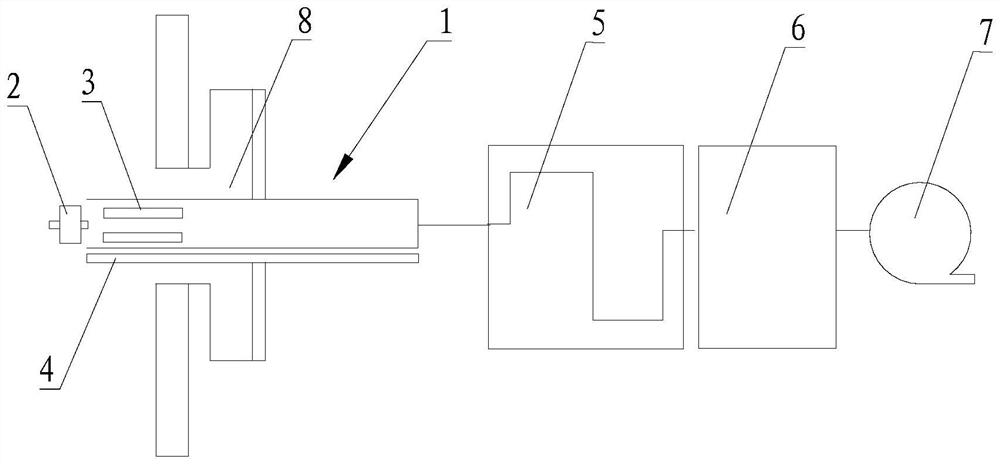

A sampling device and nano-gold technology, applied in sampling devices, chemical instruments and methods, separation methods, etc., can solve problems such as inapplicability to mercury, penetration, poor repeatability, and inability to collect particulate mercury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

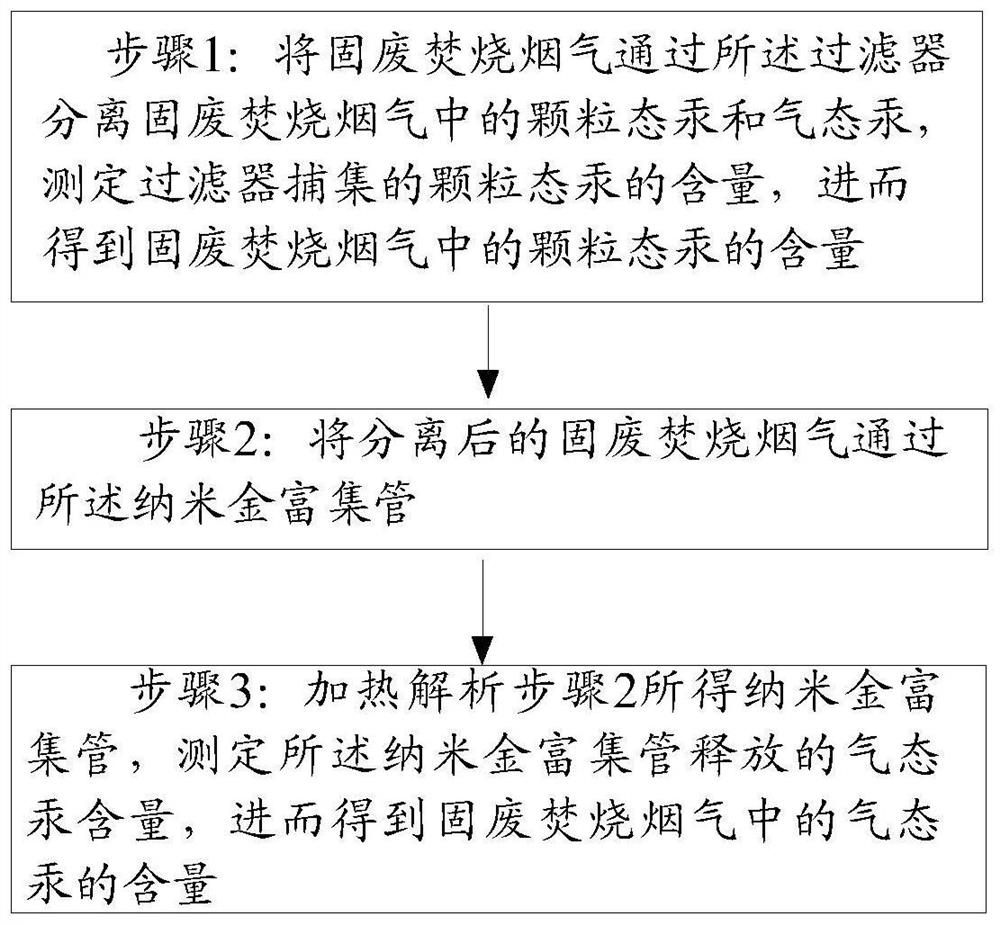

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides a kind of preparation method of nano-gold enrichment tube, comprising the following steps:

[0025] Step 1: put the carrier into 10% dilute nitric acid solution, heat and boil for 1 hour, wash it with distilled water several times, dry it at a constant temperature of 110°C for 1 hour, and cool it for later use;

[0026] Step 2: Add 0.1-0.2M sodium borohydride solution 3-5mL and 0.9-1.0wt% tetrakis hydroxymethyl phosphorus chloride solution 1-2mL in 100mL of 0.01-0.03% tetrachloroauric acid solution, at 1000r / min heated and stirred at a temperature of 70° C. to obtain a brown gold sol;

[0027] Step 3: Continue heating and stirring the gold sol, and at the same time add 1.0-4.0 mL of a 1% trisodium citrate solution to prepare gold nanoparticles with a particle size of 10-30 nm;

[0028] Step 4: Immerse the carrier obtained in step 1 in the mixed solution obtained in step 3 with uniform stirring, and then put it into a microwave oven to hea...

Embodiment 1

[0057] A preparation method of nano-gold enrichment tube, comprising the following steps:

[0058] Step 1: put the carrier into 10% dilute nitric acid solution, heat and boil for 1 hour, wash it with distilled water several times, dry it at a constant temperature of 110°C for 1 hour, and cool it for later use;

[0059] Step 2: Add 0.15M sodium borohydride solution 4mL and 0.95wt% tetrakishydroxymethyl phosphorus chloride solution 1.5mL in the 0.02% tetrachloroauric acid solution of 100mL, with the rotating speed of 1000r / min, the temperature condition of 70 ℃ Heat and stir to obtain brown gold sol;

[0060] Step 3: continuously heating and stirring the gold sol, and adding 2.5 mL of a 1% trisodium citrate solution at the same time to obtain gold nanoparticles with a particle size of 20 nm;

[0061] Step 4: Immerse the carrier obtained in step 1 in the mixed solution obtained in step 3 with uniform stirring, and then put it into a microwave oven for heating and drying with a m...

Embodiment 2

[0065] A preparation method of nano-gold enrichment tube, comprising the following steps:

[0066] Step 1: put the carrier into 10% dilute nitric acid solution, heat and boil for 1 hour, wash it with distilled water several times, dry it at a constant temperature of 110°C for 1 hour, and cool it for later use;

[0067] Step 2: Add 0.1M sodium borohydride solution 3mL and 0.9wt% tetrakishydroxymethyl phosphorus chloride solution 1mL in 100mL of 0.01% tetrachloroauric acid solution, carry out with the rotating speed of 1000r / min, the temperature condition of 70 ℃ Heat and stir to obtain brown gold sol;

[0068] Step 3: continuously heating and stirring the gold sol, and adding 1 mL of a 1% trisodium citrate solution at the same time to obtain gold nanoparticles with a particle size of 10 nm;

[0069] Step 4: Immerse the carrier obtained in step 1 in the mixed solution obtained in step 3 with uniform stirring, and then put it into a microwave oven for heating and drying with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com