Preparation method of black titanium dioxide B nanosheet with high oxygen vacancy content defects

A black titanium dioxide, nanosheet technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of wide band gap, low light utilization rate, etc., achieve uniform particle size, increase specific surface area, enhance The effect of photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

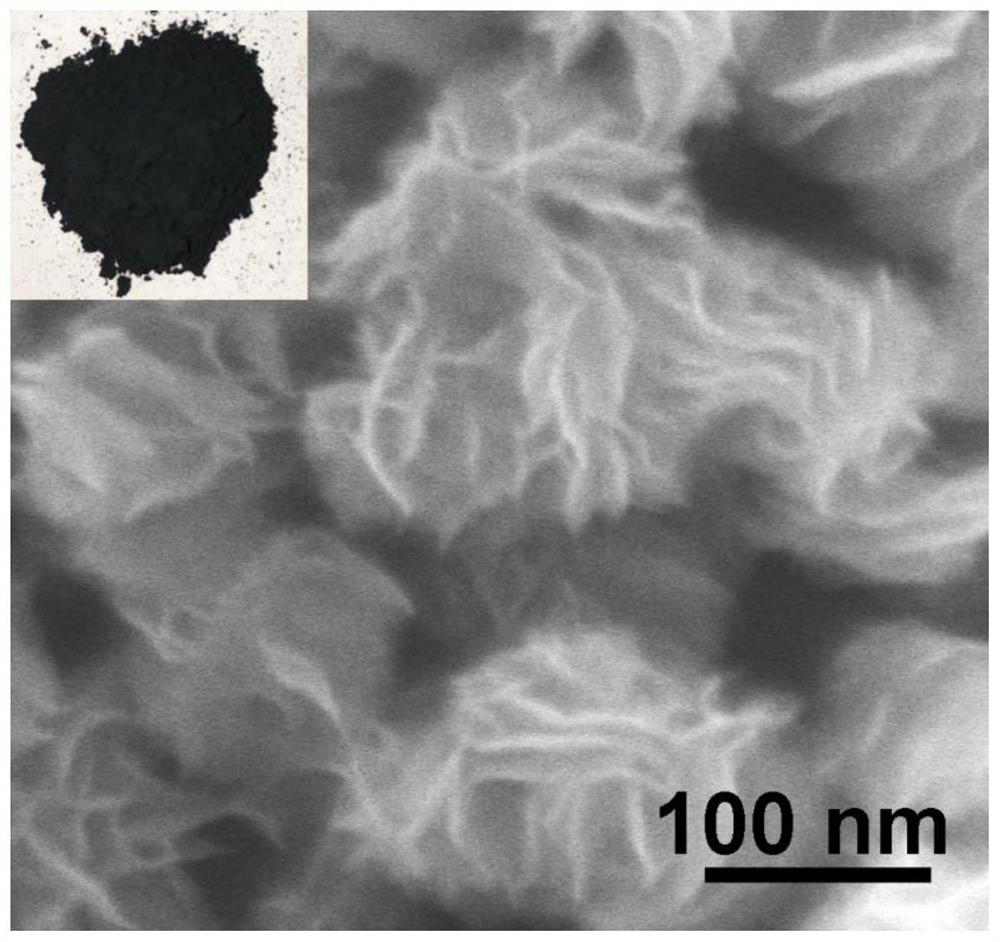

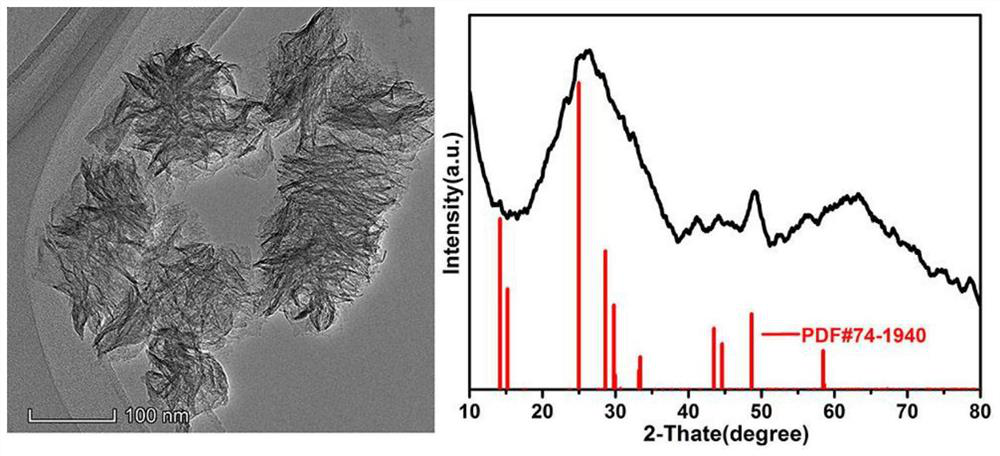

[0029] Add 2ml of titanium tetrachloride hydrochloric acid solution into 20ml of ethylene glycol, and stir evenly until the color of the solution is light brown. The obtained light brown solution was transferred to a 50ml reaction kettle, placed in a 150°C incubator, kept for 4 hours, and a white precipitate was obtained after cooling. Centrifuged, washed with ethanol, dried at 30°C for 10 hours, ground and placed in a porcelain ark, moved to a tube furnace, and annealed at 250°C for 2 hours under the protection of nitrogen to obtain a brown titanium dioxide B nanosheet sample.

Embodiment 2

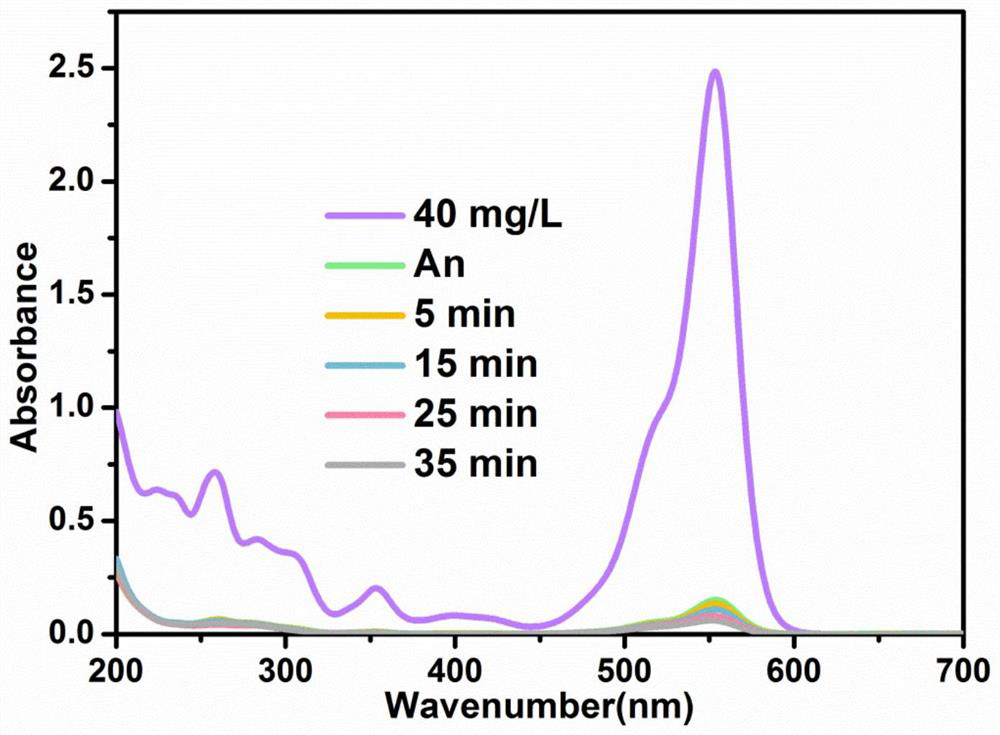

[0031] Add 2ml of titanium tetrachloride hydrochloric acid solution into 20ml of ethylene glycol, and stir evenly until the color of the solution is light brown. The obtained light brown solution was transferred to a 50ml reaction kettle, placed in a 150°C incubator, kept for 4 hours, and a white precipitate was obtained after cooling. After centrifugation, washing with ethanol, drying at 30°C for 10 hours, grinding, putting into a porcelain ark, moving to a tube furnace, and annealing at 350°C for 2 hours under the protection of nitrogen to obtain black titanium dioxide B nanosheet samples. Take 20mg of black sample and place it in 20ml of 40mg / L RhB solution. After dark reaction for 30min, keep the supernatant for testing, then irradiate under simulated sunlight for 5min, 15min, 25min, 35min and keep the supernatant for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com