Resourceful treatment and utilization method of ardealite leachate

A technology of leachate and phosphogypsum, applied in the field of environmental engineering, can solve problems such as a large amount of solid waste, corrosion of pipeline equipment, and degradation of phosphoric acid quality, and achieve the effects of practical and reliable treatment process, high removal rate, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

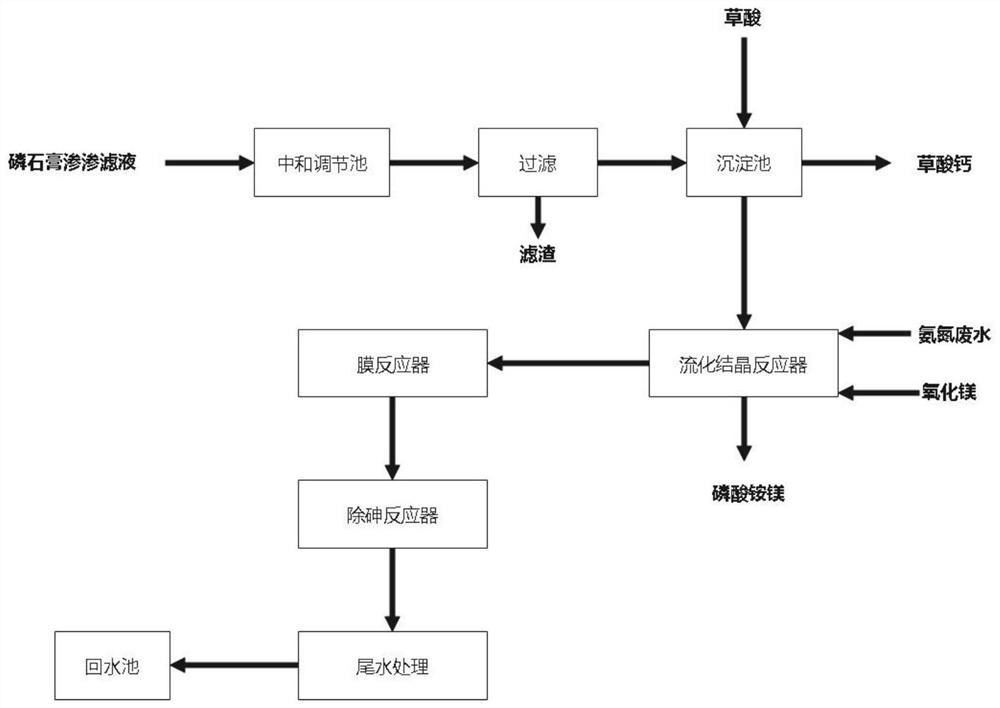

Method used

Image

Examples

Embodiment 1

[0032] 1) to 30% strength phosphogypsum leachate appropriate amount of sodium hydroxide solution to remove part of the impurities, adjusting the pH of the solution to between 4-5 and stirred for 10-20min the reaction time, the reaction temperature is room temperature, completion of the reaction after filtration, the filtrate was retained.

[0033] 2) To the filtrate obtained adding oxalic acid, the molar ratio of the dosage of calcium oxalate is 1.3: 1, the reaction mixture was stirred at room temperature while adjusting the pH of the solution to 5 to 6 with sodium hydroxide solution, the reaction was stirred time is 20-30min, after the reaction, was filtered, and the filtrate obtained with calcium oxalate.

[0034] 3) induce crystallization fluidized bed reactor ammonia nitrogen wastewater and adding magnesium oxide to the resulting filtrate, to control the dosage in N: Mg: P = 1.1: 1.2: 1, while a 30% sodium hydroxide solution PH value is adjusted to 8 to 10, the reaction was st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com