Self-intercalation vanadium-based two-dimensional nanosheet, preparation method and application thereof

A two-dimensional nanometer and nanosheet technology, applied in nanotechnology, chemical instruments and methods, vanadium compounds, etc., can solve the problems of high equipment requirements and increased cost, and achieve the effects of stable chemical properties, low cost and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a V 8 (S 1-x Se x ) 15 Nano sheet, its preparation method specifically comprises the following steps:

[0039] 1) Put 0.1g V 2 o 5 The powder is placed in the quartz boat, and the clean sapphire substrate is buckled on the V 2 o 5 Put the powdered quartz boat on the downstream of the quartz tube of the dual-temperature zone tube furnace; mix 0.9g of S powder and 0.3g of Se powder evenly, place it in the quartz boat, and place it upstream of the quartz tube of the dual-temperature zone tube furnace;

[0040] 2) After cleaning the quartz tube repeatedly with argon, within 30 minutes, raise the temperature of the downstream furnace to 670°C and the temperature of the upstream furnace to 240°C, and keep the carrier gas Ar flow rate at 100 sccm, H 2 The flow rate is 10 sccm, and after 30 minutes of growth, it is naturally cooled to room temperature, and the V grown on the sapphire substrate is obtained. 8 (S 1-x Se x ) 15 Nanosheets.

Embodiment 2

[0042] This embodiment provides a V 8 (S 1-x Se x ) 15 Nano sheet, its preparation method specifically comprises the following steps:

[0043] 1) Put 0.1g V 2 o 5 The powder is placed in the quartz boat, and the clean sapphire substrate is buckled on the V 2 o 5 Put the powdered quartz boat on the downstream of the quartz tube of the dual-temperature zone tube furnace; mix 0.9g of S powder and 0.45g of Se powder evenly, place it in the quartz boat, and place it upstream of the quartz tube of the dual-temperature zone tube furnace;

[0044] 2) After cleaning the quartz tube repeatedly with argon, within 30 minutes, raise the temperature of the downstream furnace to 640°C and the temperature of the upstream furnace to 250°C. 2 The flow rate is 10 sccm, and after 30 minutes of growth, it is naturally cooled to room temperature, and the V 8 (S 1-x Se x ) 15 Nanosheets.

Embodiment 3

[0046] This embodiment provides a V 8 (S 1-x Se x ) 15 Nano sheet, its preparation method specifically comprises the following steps:

[0047] 1) Put 0.1g V 2 o 5 The powder is placed in the quartz boat, and the clean sapphire substrate is buckled on the V 2 o 5 Put the powdered quartz boat on the downstream of the quartz tube of the dual-temperature zone tube furnace; mix 0.9g of S powder and 0.9g of Se powder evenly, place it in the quartz boat, and place it upstream of the quartz tube of the dual-temperature zone tube furnace;

[0048] 2) After repeatedly cleaning the quartz tube with argon, within 30 minutes, raise the temperature of the downstream furnace to 650°C, and the temperature of the upstream furnace to 260°C, and keep the carrier gas Ar flow rate at 100 sccm, H 2 The flow rate is 10 sccm, and after 30 minutes of growth, it is naturally cooled to room temperature, and the V 8 (S 1-x Se x ) 15 Nanosheets.

PUM

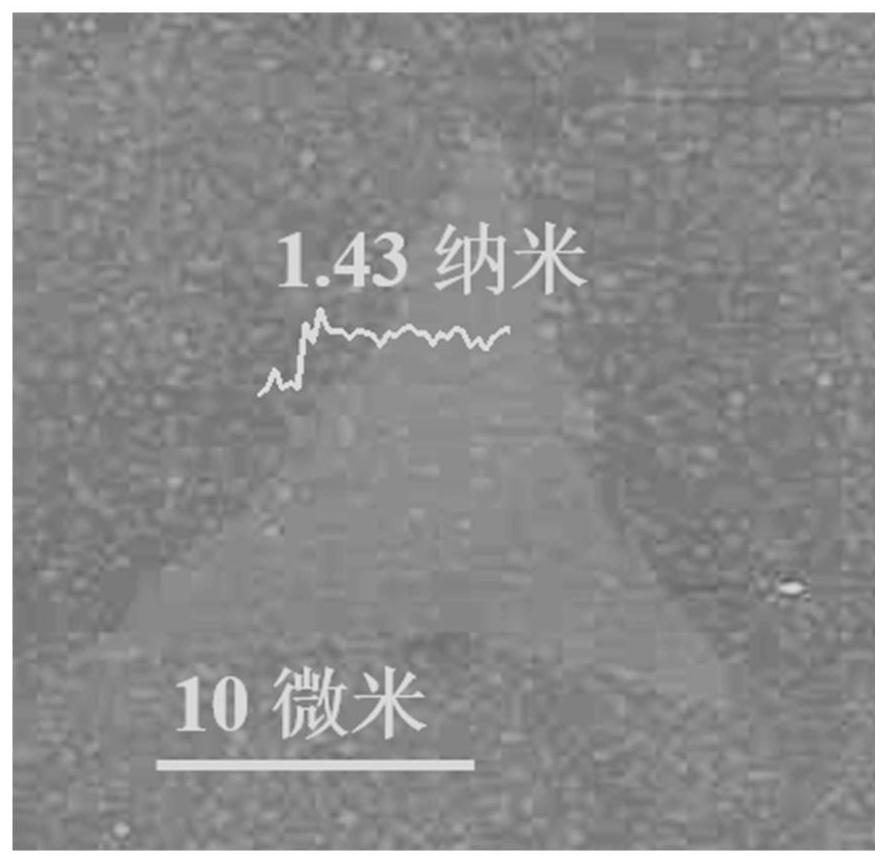

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com