MnO2 nanobelt/nitrogen-doped graphene aerogel composite material for supercapacitor as well as preparation method and application of MnO2 nanobelt/nitrogen-doped graphene aerogel composite material

A nitrogen-doped graphene, supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of damage to the conductivity and structural stability of composite materials, poor conductivity and structural stability of composite materials , graphene-carbon skeleton structural integrity damage and other problems, to achieve the effect of being conducive to rapid transmission, improving electrochemical performance, and excellent supercapacitor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of MnO for supercapacitor 2 The preparation method of nanobelt / nitrogen-doped graphene airgel composite material comprises steps as follows:

[0046] (1) To 7.5mL concentration is 5.3mg mL -1 Add 12.5mL of Tris-HCl buffer solution (concentration is 0.1mol L -1 , pH is 8.5), fully stirred and mixed evenly, then added 20mg of dopamine, ultrasonicated for 40min, oscillated for 10min, after mixing evenly, the resulting mixture was transferred to a 50mL autoclave, and reacted at 180°C for 12h; after the reaction was completed, poly Dopamine-reduced graphene oxide hydrogel, the obtained polydopamine-reduced graphene oxide hydrogel was washed 5 times with pure water, freeze-dried at -65°C for 72h, and then heat-treated at 800°C for 3h under Ar atmosphere, The obtained nitrogen-doped graphene airgel is denoted as NGA.

[0047] (2) Add 30.0mg of the nitrogen-doped graphene airgel obtained in step (1) into 50mL with a concentration of 2.6mg mL -1 KMnO 4 In the solutio...

Embodiment 2

[0064] A kind of MnO for supercapacitor 2 The preparation method of the nanobelt / nitrogen-doped graphene airgel composite is as described in Example 1, except that the reaction time in step (3) is 21 min.

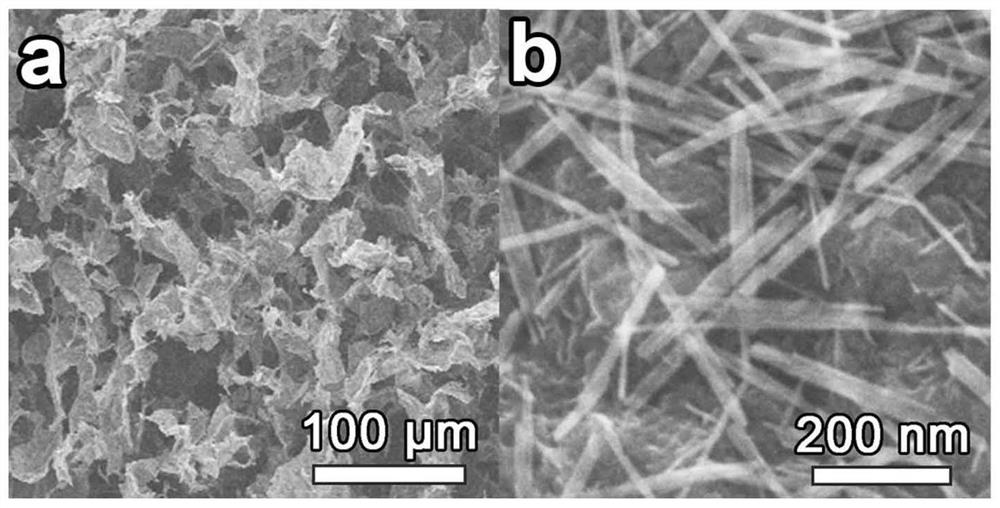

[0065] The MnO prepared in this example 2 SEM images of nanobelt / nitrogen-doped graphene airgel composites Figure 9 As shown in a, from Figure 9 a It can be seen that MnO 2 Nanoribbons grow uniformly on nitrogen-doped graphene aerogels.

[0066] The MnO prepared in this example 2 The nanoribbon / nitrogen-doped graphene airgel composite was tested for electrochemical performance, and it was assembled into a solid-state ASC for performance testing. The method is as described in Example 1.

[0067] In a three-electrode system, at 0.5A g -1 Current density, MnO 2 The specific capacitance of the nanoribbon / nitrogen-doped graphene airgel composite is 647.5 F g -1 . MNRs / NGA / / AC ASC at 0.5A g -1 The specific capacitance corresponding to the current density is 158.2Fg -...

Embodiment 3

[0069] A kind of MnO for supercapacitor 2 The preparation method of the nanobelt / nitrogen-doped graphene airgel composite is as described in Example 1, except that the reaction time in step (3) is 14 minutes.

[0070] The MnO prepared in this example 2 SEM images of nanobelt / nitrogen-doped graphene airgel composites Figure 9 As shown in b, from Figure 9 b It can be seen that the MnO 2 Nanoribbons grow uniformly on nitrogen-doped graphene aerogels.

[0071] The MnO prepared in this example 2 The nanoribbon / nitrogen-doped graphene airgel composite was tested for electrochemical performance, and it was assembled into a solid-state ASC for performance testing. The method is as described in Example 1.

[0072] In a three-electrode system, at 0.5A g -1 Current density, MnO 2 The specific capacitance of the nanoribbon / nitrogen-doped graphene airgel composite is 643.1 F g -1 . MNRs / NGA / / AC ASC at 0.5A g -1 The specific capacitance corresponding to the current density is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com