Tuff-based green ecological concrete and preparation method thereof

A technology of ecological concrete and tuff, applied in ceramic products, other household utensils, applications, etc., can solve the problems of soil nutrient loss, poor durability, soil moisture and fertility decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

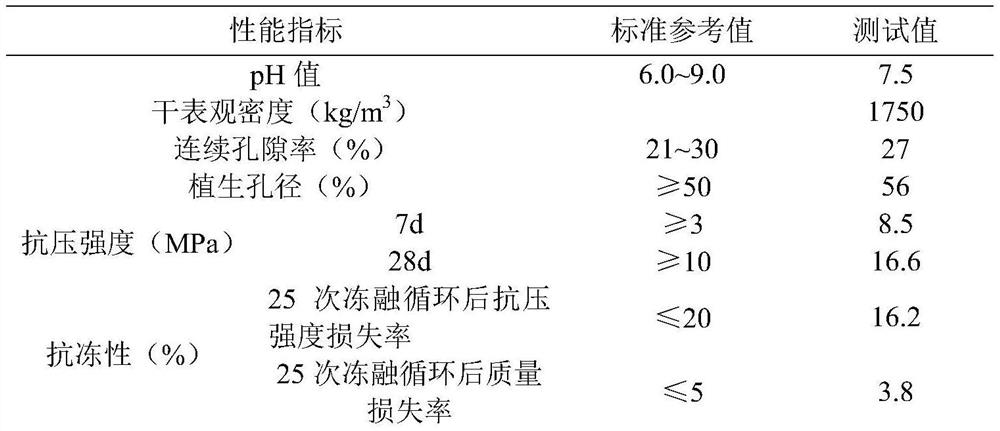

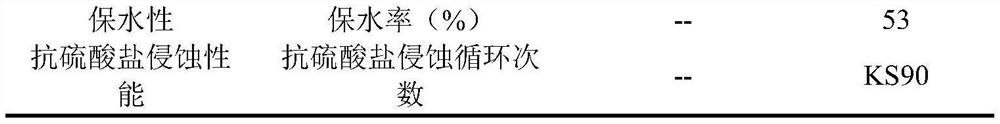

Embodiment 1

[0032] A kind of tuff base green ecological concrete, its preparation method comprises the steps:

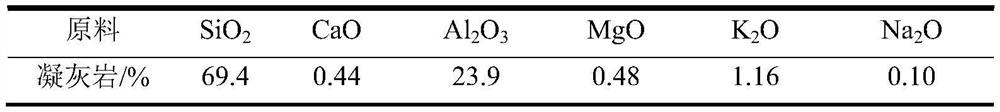

[0033] 1) Use a jaw crusher to crush the tuff for 1 minute until the particle size is 5-10 mm to obtain tuff particles; then take part of the tuff particles and continue ball milling for 1 hour, and the bulk density of the tuff after ball milling is 2.49 g / cm 3 , with a specific surface area of 450m 2 / kg, get tuff powder;

[0034] 2) Weigh 100 g of graphene oxide dispersion (aqueous solution) with a concentration of 3 wt%, add 0.8 g of potassium dihydrogen phosphate, 1.0 g of sodium dihydrogen phosphate, 2.6 g of carbonamide, and 15 g of water into it, and carry out fermentation compounding for 48 hours at the same time , the fermentation temperature was controlled at 60°C, after fermentation, 2.8g of polycarboxylate superplasticizer was added and mixed evenly to obtain a composite admixture;

[0035] 3) Weigh 120 parts of tuff powder, 30 parts of tuff particles, 80 parts o...

Embodiment 2

[0043] A kind of tuff base green ecological concrete, its preparation method comprises the steps:

[0044] 1) Use a jaw crusher to crush the tuff to a particle size of 5-10mm to obtain tuff particles; take part of the tuff particles and continue ball milling for 1 hour, and the bulk density of the tuff after ball milling is 2.54g / cm 3 , the specific surface area is 500m 2 / kg, get tuff powder;

[0045] 2) Weigh 80g of 5wt% graphene oxide dispersion, add 1.0g potassium dihydrogen phosphate, 1.2g sodium dihydrogen phosphate, 3.0g carbonamide, 15g water to it, and ferment for 48 hours at the same time, and the fermentation temperature is controlled at 60°C. After fermentation, add 3.4g of polycarboxylate superplasticizer, mix evenly, and obtain a composite admixture;

[0046] 3) Weigh 140 parts of tuff powder, 50 parts of tuff particles, 100 parts of fly ash, 70 parts of kaolin, 50 parts of composite admixture, 300 parts of desert sand, 100 parts of high-performance hollow glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com