Functionalized MOFs material for improving stability of AlH3 as well as preparation method and application of functionalized MOFs material

A functional and stable technology, applied in the field of functionalized MOFs materials and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029]The present invention also provides a preparation method of the functionalized MOFs material, comprising the following steps:

[0030] Step1: Dissolve zirconium tetrachloride, 2-aminoterephthalic acid, and benzoic acid in the DMF solution at a molar ratio of 1:1:20, then put them into a stainless steel hydrothermal reaction kettle and mix evenly. React for 24 hours, cool slowly until the temperature drops to room temperature, and obtain a yellow powder. Centrifuge the powder with DMF solution for 3 to 4 times to remove unreacted ligands and metal ions; use ethanol as the extraction agent, and extract with Soxhlet for three days , remove the residual DMF solution to obtain a solid powder; dry and activate the obtained solid powder at 60°C for 8 hours to obtain a nanoscale metal-organic framework material matrix UiO-66-NH 2 ;

[0031] Step2: The prepared nanoscale metal organic framework material matrix UiO-66-NH 2 Stir and react with isocyanate at a specific temperature...

Embodiment 1

[0036] The synthesis of the TEMPO functionalized MOFs material of the present embodiment is as follows:

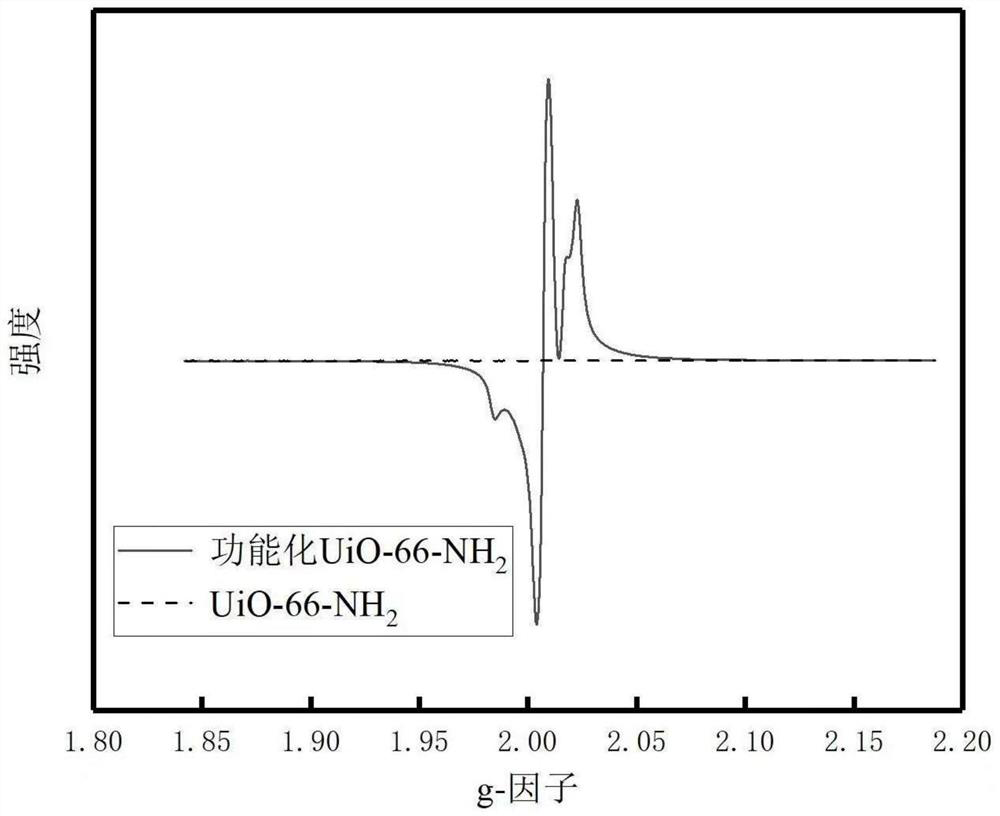

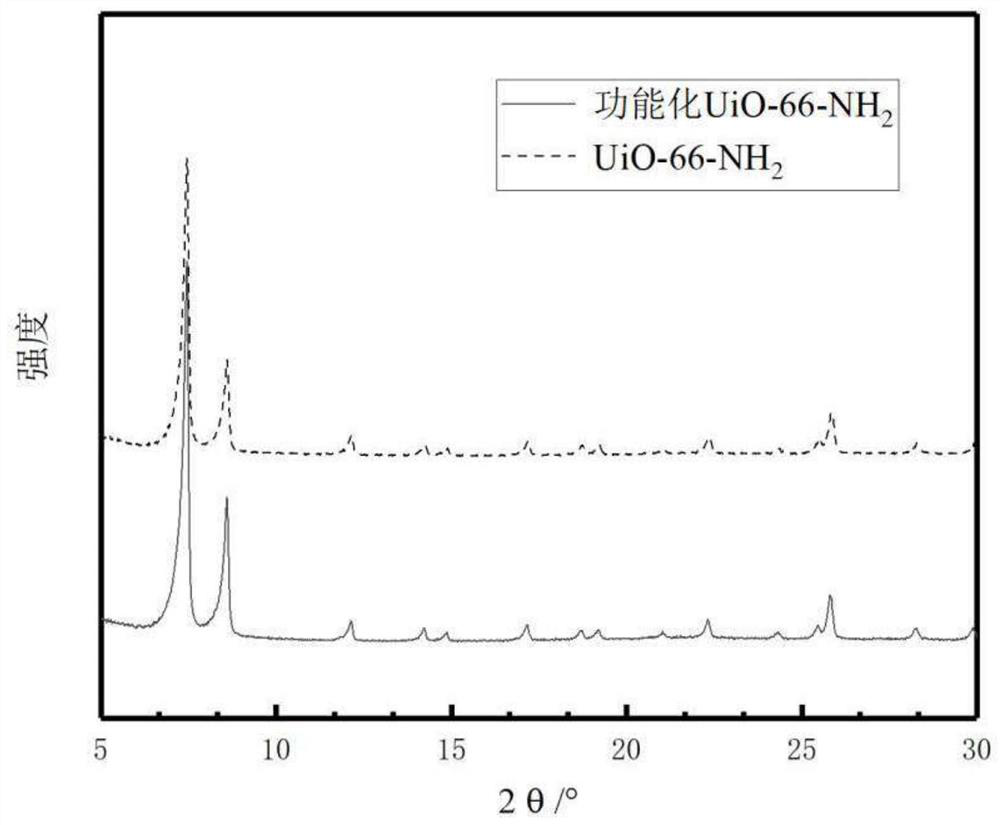

[0037] 8g metal organic framework material matrix UiO-66-NH 2 Dissolve the powder in 30ml of anhydrous DMF, add 15ml of isocyanate, and stir for 6 hours at 30°C in a closed and anhydrous environment to prepare an active MOFs solution whose terminal group is isocyanate, and repeatedly centrifuge and wash it with anhydrous DMF solution 4 to 5 times to obtain solid active MOFs. see figure 1 , is the electron paramagnetic resonance (EPR) spectrum of the MOFs material before and after the TEMPO functionalization; the triple broad peak at g=2.006 place in the spectrum coincides with the spectrum peak of the TEMPO free radical, indicating that by the functionalization method of Example 1, the TEMPO free radical is successfully Grafted onto the surface of MOFs material. figure 2 It is the X-ray diffraction (XRD) pattern of MOFs material before and after TEMPO functionalization...

Embodiment 2

[0041] The preparation method of TEMPO functionalized MOFs material described in this embodiment is the same as embodiment 1, when grafting TEMPO on the surface of MOFs, H 2 The molar ratio of N-TEMPO and MOFs is also consistent with Example 1, but the reaction condition is 40°C.

[0042] Integrating TEMPO-functionalized MOFs with AlH 3 Grind and mix well according to the mass ratio of 1:100, then heat at 60°C for 48 hours in an air atmosphere, and measure the modified AlH by the drainage method 3 hydrogen release volume.

[0043] After heating for 72 hours at 60°C in an air atmosphere, AlH with functionalized modified MOFs materials was measured by the drainage method. 3 The hydrogen release volume is 91ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com