Bio-organic fertilizer and preparation method thereof

A bio-organic fertilizer and microbial technology, applied in organic fertilizers, fertilizers made from biological waste, inorganic fertilizers, etc., can solve the problems of soil pollutant remediation, insufficient soil improvement, and weaker crop yield improvement than chemical fertilizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

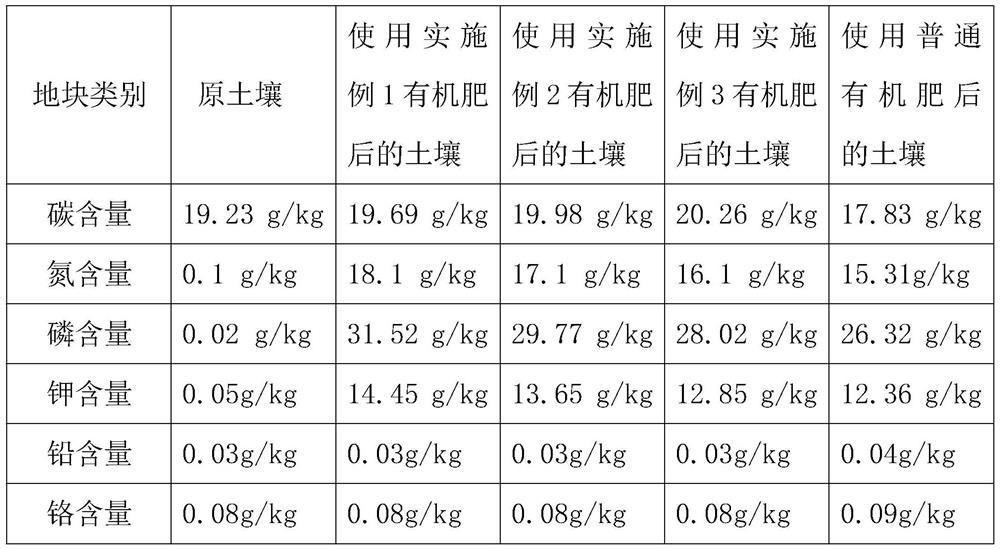

Examples

Embodiment 1

[0022] S1. Preparation of straw charcoal: using rice straw as raw material, first crush the rice straw, put it into the pyrolysis furnace after the crushing is completed, the temperature of the pyrolysis furnace is controlled at 300°C, and the straw is processed slowly under the condition of anoxic Decompose for 4 hours to obtain straw charcoal;

[0023] S2. Preparation of fermented poultry manure: 75% chicken manure, 8% trace element auxiliary materials, 6% soybean bran and 11% fermented auxiliary materials are all added to the mixing container by weight percentage, and they are evenly mixed to obtain fermented poultry manure. Elemental auxiliary materials are mixed with nitrogen, phosphorus pentoxide and potassium oxide in a weight ratio of 3:3:1;

[0024] S3, preparation of base fertilizer: 2.5% molasses, 2.5% microbial beneficial bacteria and 95% fermented poultry manure are all added in the mixing container by weight percentage, mixed evenly, and finally base fertilizer i...

Embodiment 2

[0027] S1. Preparation of straw charcoal: using rice straw as raw material, first crush the rice straw, put it into the pyrolysis furnace after the crushing is completed, the temperature of the pyrolysis furnace is controlled at 500°C, and the straw is processed slowly under the condition of anoxic Decompose for 5 hours to obtain straw charcoal;

[0028] S2. Preparation of fermented poultry manure: 83% chicken manure, 5% trace element auxiliary materials, 4% soybean bran and 8% fermented auxiliary materials are all added to the mixing container by weight percentage, and they are uniformly mixed to obtain fermented poultry manure. Elemental auxiliary materials are mixed with nitrogen, phosphorus pentoxide and potassium oxide in a weight ratio of 3:4:2;

[0029] S3, preparation of base fertilizer: 3.75% molasses, 3.75% microbial beneficial bacteria and 92.5% fermented poultry manure are all added in the mixing container by weight percentage, mixed evenly, and finally base fertil...

Embodiment 3

[0032] S1. Preparation of straw charcoal: using rice straw as raw material, first crush the rice straw, put it into the pyrolysis furnace after the crushing is completed, the temperature of the pyrolysis furnace is controlled at 700°C, and the straw is processed slowly under the condition of anoxic Decompose for 6 hours to obtain straw charcoal;

[0033] S2. Preparation of fermented poultry manure: 90% chicken manure, 3% trace element auxiliary materials, 2% soybean bran and 5% fermented auxiliary materials are all added to the mixing container by weight percentage, and they are evenly mixed to obtain fermented poultry manure. Elemental auxiliary materials are mixed with nitrogen, phosphorus pentoxide and potassium oxide in a weight ratio of 4:5:4;

[0034] S3, preparation of base fertilizer: 5% molasses, 5% microbial beneficial bacteria and 90% fermented poultry manure are all added in the mixing container by weight percentage, mixed evenly, and finally base fertilizer is obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com