Method for continuously preparing polyisobutene

A technology of polyisobutylene and isobutylene, which is applied in the field of continuous preparation of polyisobutene, can solve the problems of non-continuous preparation, material performance needs to be improved, and complex preparation methods of polyisobutylene, etc., and achieves the effects of continuous preparation, convenient operation and improved high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

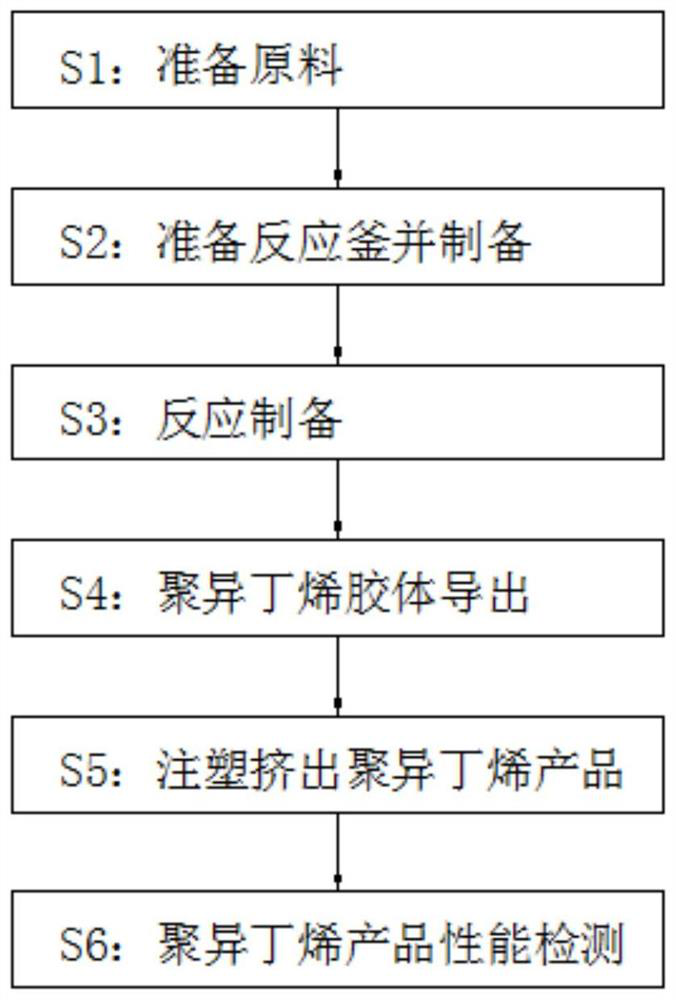

[0031] refer to figure 1 , a method for continuously preparing polyisobutylene, comprising the following preparation steps:

[0032] S1: Preparation of raw materials: organic liquid, isobutene, 1-butene, 2-butene, Lewis acid catalyst, antioxidant and anti-aging agent components, high-temperature resistant agent components, antioxidant and anti-aging agent components include sodium carbonate, benzoyl chloride ;High temperature resistant agent components include polyolefin, mica powder;

[0033] S2: Prepare the reactor and prepare: Prepare two connected reactors, the two reactors are A reactor and B reactor, first clean the two reactors, then add the organic liquid into the A reactor, and Control the temperature of the reactor, add isobutene, 1-butene, and 2-butene to the organic liquid in A reactor and fully mix, intermittently add a Lewis acid catalyst, and carry out polymerization reaction to obtain a semi-finished polyisobutene liquid;

[0034] S3: Reaction preparation: Se...

Embodiment 2

[0049] refer to figure 1 , a method for continuously preparing polyisobutylene, comprising the following preparation steps:

[0050] S1: Prepare raw materials: organic liquid, isobutylene, 1-butene, 2-butene, Lewis acid catalyst, antioxidant and anti-aging agent components, high-temperature resistant agent components, and antioxidant and anti-aging agent components include epoxy resin, methyl Hydroxypropyl acrylate; high temperature resistant agent components include aluminate coupling agent, polyisoprene raw materials;

[0051] S2: Prepare the reactor and prepare: Prepare two connected reactors, the two reactors are A reactor and B reactor, first clean the two reactors, then add the organic liquid into the A reactor, and Control the temperature of the reactor, add isobutene, 1-butene, and 2-butene to the organic liquid in A reactor and fully mix, intermittently add a Lewis acid catalyst, and carry out polymerization reaction to obtain a semi-finished polyisobutene liquid;

...

Embodiment 3

[0067] refer to figure 1 , a method for continuously preparing polyisobutylene, comprising the following preparation steps:

[0068] S1: Preparation of raw materials: organic liquid, isobutylene, 1-butene, 2-butene, Lewis acid catalyst, antioxidant and anti-aging agent components, high-temperature resistant agent components, and antioxidant and anti-aging agent components include tributoxyethyl phosphoric acid Esters and polyolefins; high temperature resistant agent components include polyimide and polyamide fibers;

[0069] S2: Prepare the reactor and prepare: Prepare two connected reactors, the two reactors are A reactor and B reactor, first clean the two reactors, then add the organic liquid into the A reactor, and Control the temperature of the reactor, add isobutene, 1-butene, and 2-butene to the organic liquid in A reactor and fully mix, intermittently add a Lewis acid catalyst, and carry out polymerization reaction to obtain a semi-finished polyisobutene liquid;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com