Rose sauce refining method

A technology of rose sauce and refining method, which is applied in the field of food engineering, which can solve the problems of increasing the amount of alcohol, low content, and poor taste of rose sauce, and achieve the effect of smooth taste, high content, and no rough feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

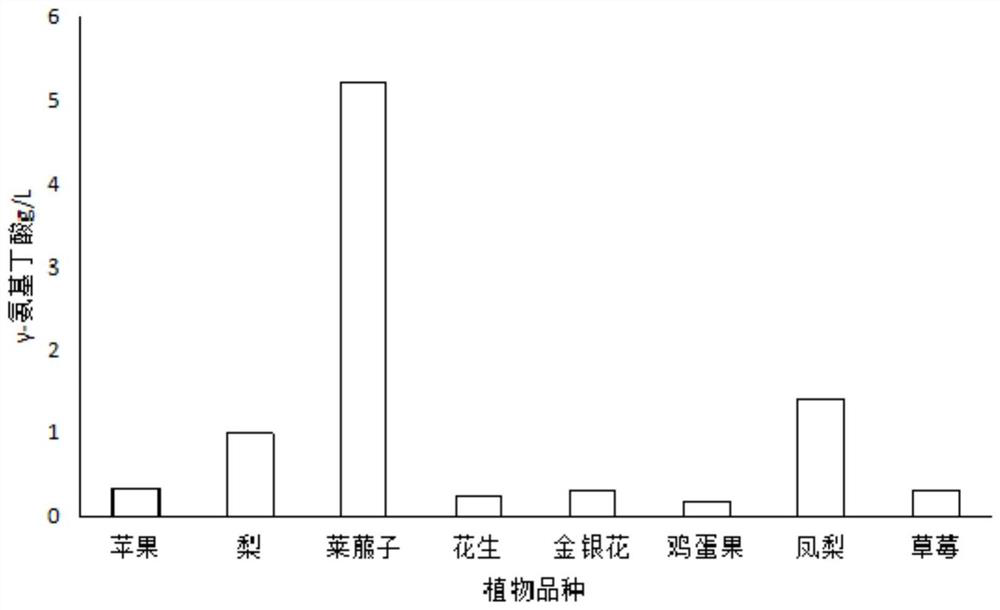

[0019] The content of γ-aminobutyric acid in different plant materials of embodiment 1

[0020] During the process of preparing rose jam, plant materials that do not affect the taste of roses are selected, and the content of gamma-aminobutyric acid in the materials is determined. The plant materials are apples, pears, radish seeds, peanuts, honeysuckle, egg fruit, pineapples and strawberries.

[0021] Referring to "Study on Fermentation of Pueraria Enzyme Rich in γ-aminobutyric Acid and Its Anti-alcohol Function", liquid chromatography was used to measure the content of GABA in each plant. The method is as follows:

[0022] (1) Weigh 0.1g of OPA, 130μL of β-mercaptoethanol and dissolve in 1mL of acetonitrile and 0.5mL of methanol, then add 0.5M boric acid solution to dilute to 20mL;

[0023] (2) Preparation of boric acid buffer solution: 0.62 g of boric acid and 0.52 g of KOH were dissolved in 20 mL of distilled water;

[0024] (3) Preparation of mobile phase A (sodium aceta...

Embodiment 2

[0031] The content of gamma-aminobutyric acid in the radish seeds produced by embodiment 2 salt stress

[0032] Grouting after the radish blooms, water once with 0.2% salt water irrigation in the grouting stage, harvest the radish seeds after the seeds are ripe, measure the content of γ-aminobutyric acid in the radish seeds according to the method of Example 1, and the measurement result is 8.29g / L, the content of γ-aminobutyric acid in radish seeds produced under salt stress increased significantly.

Embodiment 3

[0034] A method for refining rose jam, carried out according to the following steps:

[0035] (1) crushing rose petals and radish seeds to obtain a mixed powder; the mass ratio of the rose petals and radish seeds is 1:1;

[0036] (2) Mix the mixed powder prepared in step (1) with sugar and water, adjust the pH to 3.2 with citric acid, and marinate for 50 days to obtain the pickled material; add cellulase, and carry out enzymatic hydrolysis at 50°C for 14 Hour, make enzymolysis solution; The addition of described sugar is 25% of the mixed powder quality of step (1); The addition of described water is 0.6 times of step (1) mixed powder quality; The addition of described cellulase The addition amount is 200U / g pickled material;

[0037] (3) Add edible gum and honey to the enzymolysis solution prepared in step (2), boil and keep for 8 minutes to obtain rose flower sauce; the addition of the edible gum is 25% of the quality of the enzymolysis solution in step (2); The amount of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com