Polymer hybrid microporous separation membrane as well as preparation method and application thereof

A polymer and separation membrane technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane, etc., can solve the problems of complex synthesis steps, high cost, incomplete stripping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of ethylene-vinyl alcohol random copolymer:

[0043] Take a 100ml three-neck round flask, dissolve 10g of 27 mole% ethylene-vinyl acetate copolymer in 30ml of toluene at 60°C, then add 20ml of methanol-NaOH solution with a concentration of 3mol / L, heat to 80°C, and stir the reaction 8 h. After the reaction is over, pour the reaction solution into 200ml of cold HCl aqueous solution with a concentration of 1mol / L for neutralization, filter to obtain a precipitate, and repeatedly wash the precipitate with distilled water and methanol in a Buchner funnel to remove water-soluble Inorganic salts were obtained to obtain ethylene-vinyl alcohol random copolymers with 27 mole% ethylene, and dried in a vacuum oven at 40°C overnight.

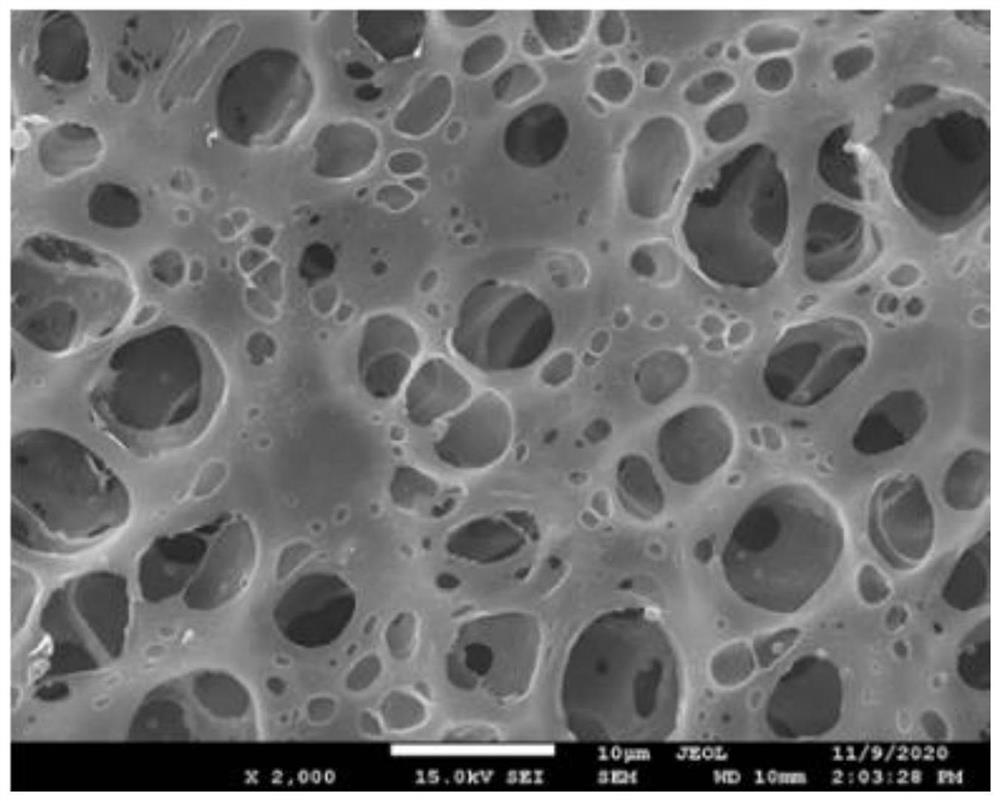

[0044] (2) Preparation of casting solution:

[0045] Dissolve 0.65g of PVDF and 0.10g of ethylene-vinyl alcohol random copolymer in 10mL of N, N'-dimethylacetamide, and stir for 24 hours in a water bath at 70°C. After all dissolve, ...

Embodiment 2

[0051] In this example, when preparing a polymer hybrid microporous separation membrane, the molar ratio of ethylene in the ethylene-vinyl alcohol random copolymer and the mass fraction of PVDF, ethylene-vinyl alcohol random copolymer, and Cyanex272 were adjusted to explore different Changes in the hydrophilicity of the polymer hybrid microporous separation membrane prepared under different conditions. The preparation method and adsorption separation operation conditions of the polymer hybrid microporous membrane in this example are basically the same as those in Example 1, and the specific addition amounts of each raw material are shown in Table 1.

[0052] Table 1. The amount of raw materials used in polymer hybrid microporous membranes

[0053]

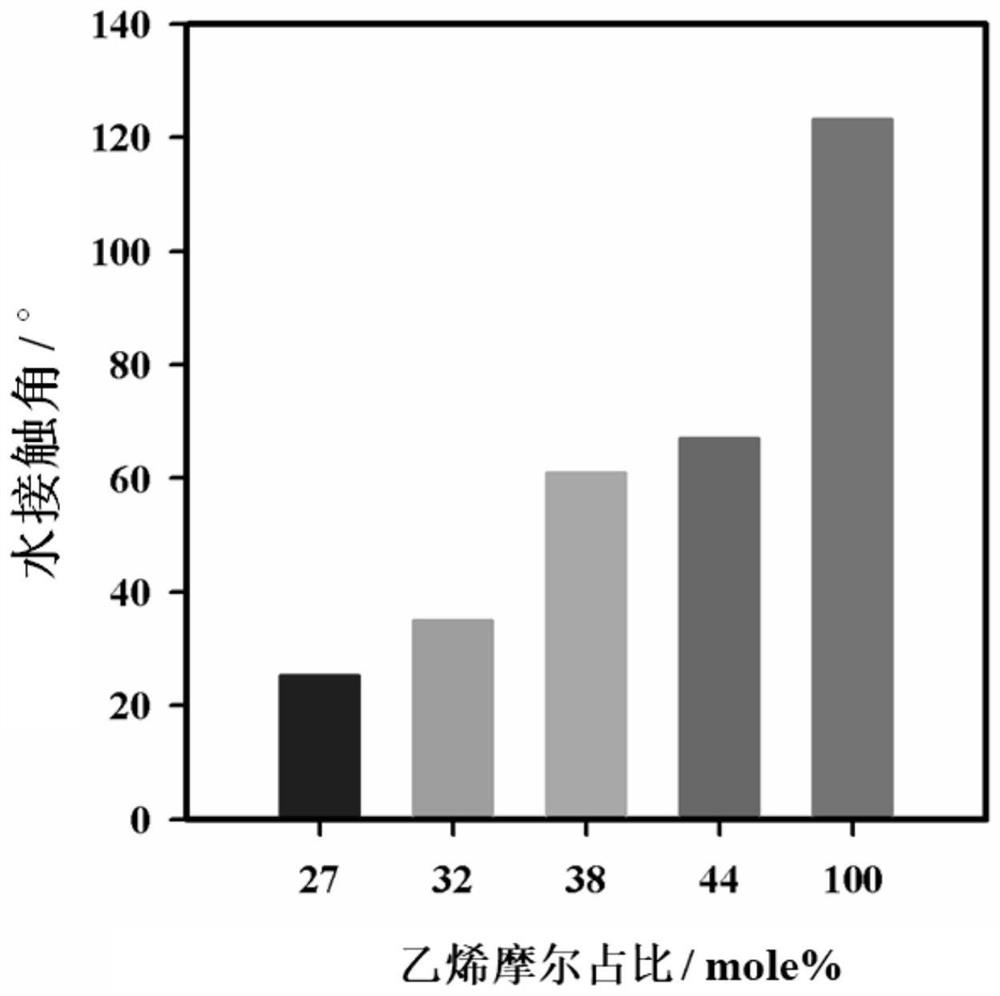

[0054] image 3 It is a comparison chart of water contact angle values of polymer hybrid microporous membranes with different ethylene molar contents, and the prepared polymer hybrid microporous membranes are the above-mentio...

Embodiment 3

[0062] In this example, when preparing the polymer hybrid microporous separation membrane, the mass fractions of PVDF, ethylene-vinyl alcohol random copolymer, and Cyanex272 were adjusted to explore the pair of polymer hybrid microporous separation membranes prepared under different conditions. Changes in the equilibrium adsorption capacity of ytterbium and lutetium.

[0063] The preparation method and adsorption separation operation conditions of the polymer hybrid microporous membrane in this example are basically the same as those in Example 1, and the specific addition amounts of each raw material are shown in Table 1. The size of the equilibrium adsorption capacity investigated in this implementation, the specific operation steps are as follows:

[0064] Accurately pipette the rare earth standard solution and prepare a 20 mg / L rare earth chloride solution with deionized water. Add dilute hydrochloric acid (1 mol L -1 ) or dilute ammonia (1 mol L -1 ) to adjust the pH o...

PUM

| Property | Measurement | Unit |

|---|---|---|

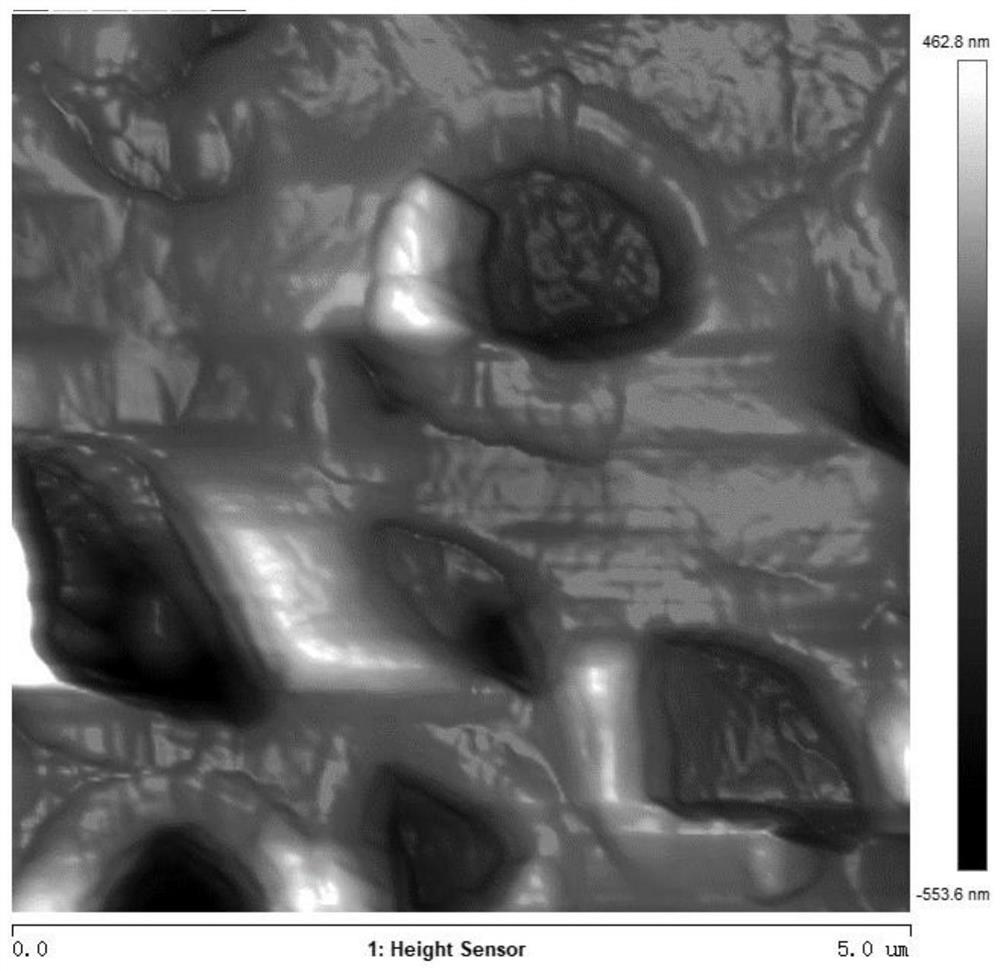

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com