Preparation method of sodium polyacrylate dispersed ferrous sulfide intercalation layered double hydroxide

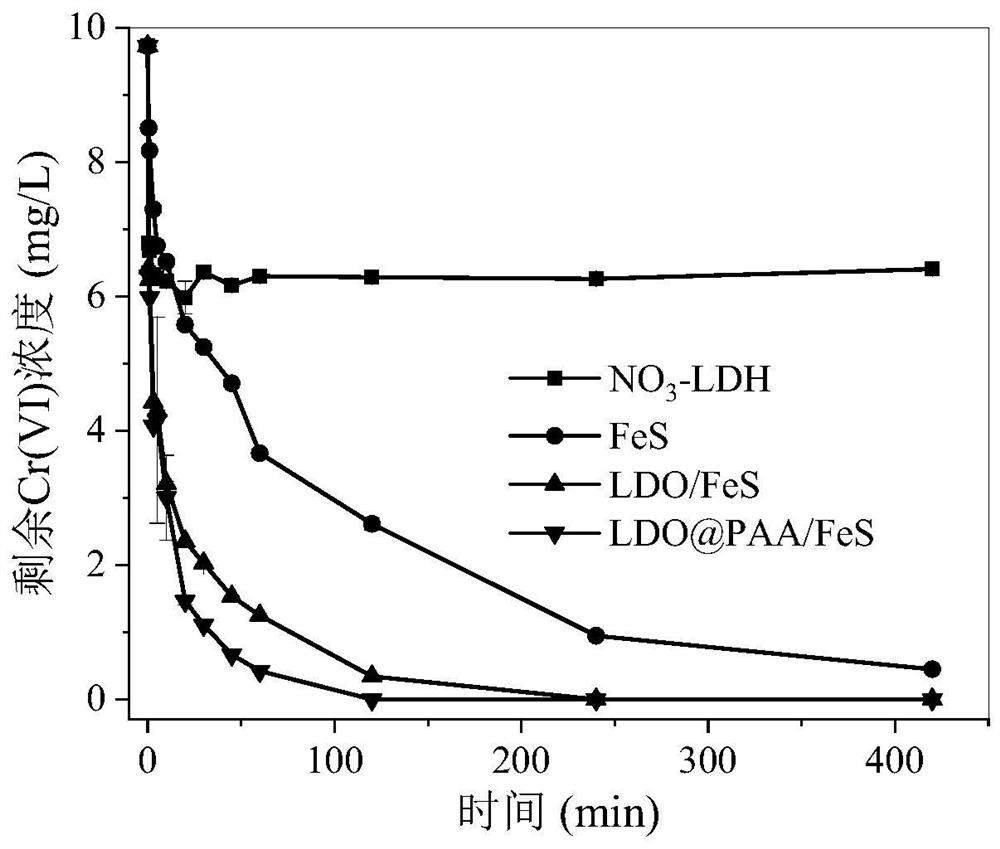

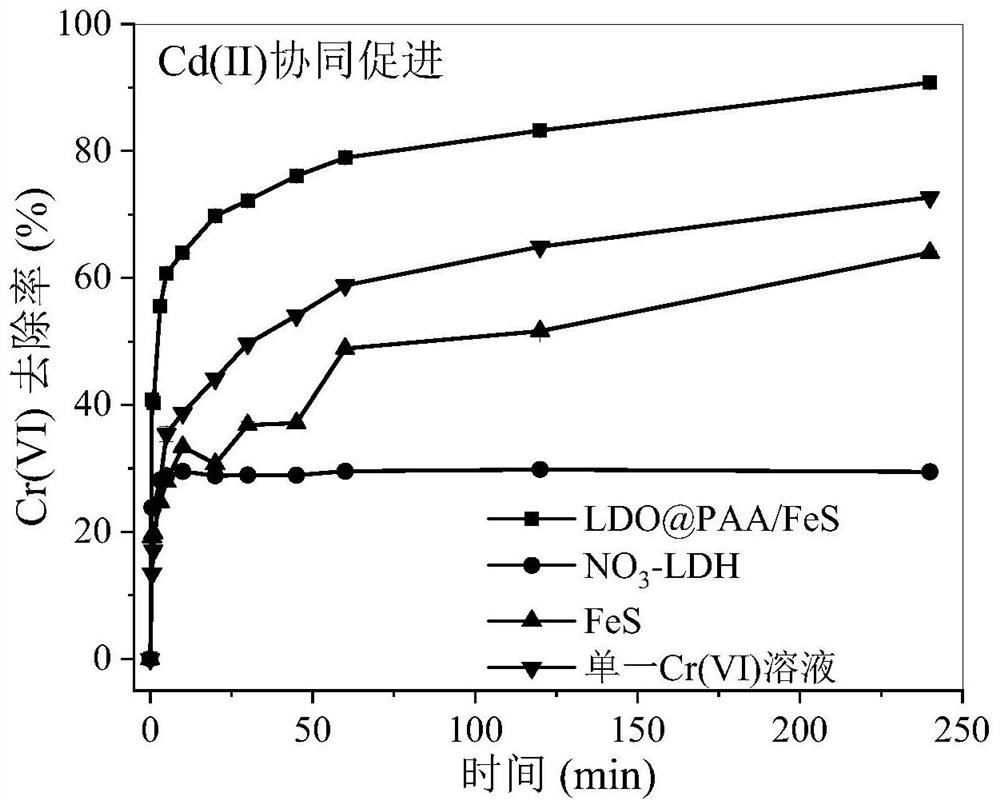

A sodium polyacrylate, double hydroxide technology, applied in the directions of alkali metal oxides/hydroxides, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of easy agglomeration and poor adsorption effect of nano-composite materials, etc. To achieve high-efficiency adsorption, reduce the toxicity of heavy metals, promote adsorption and reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

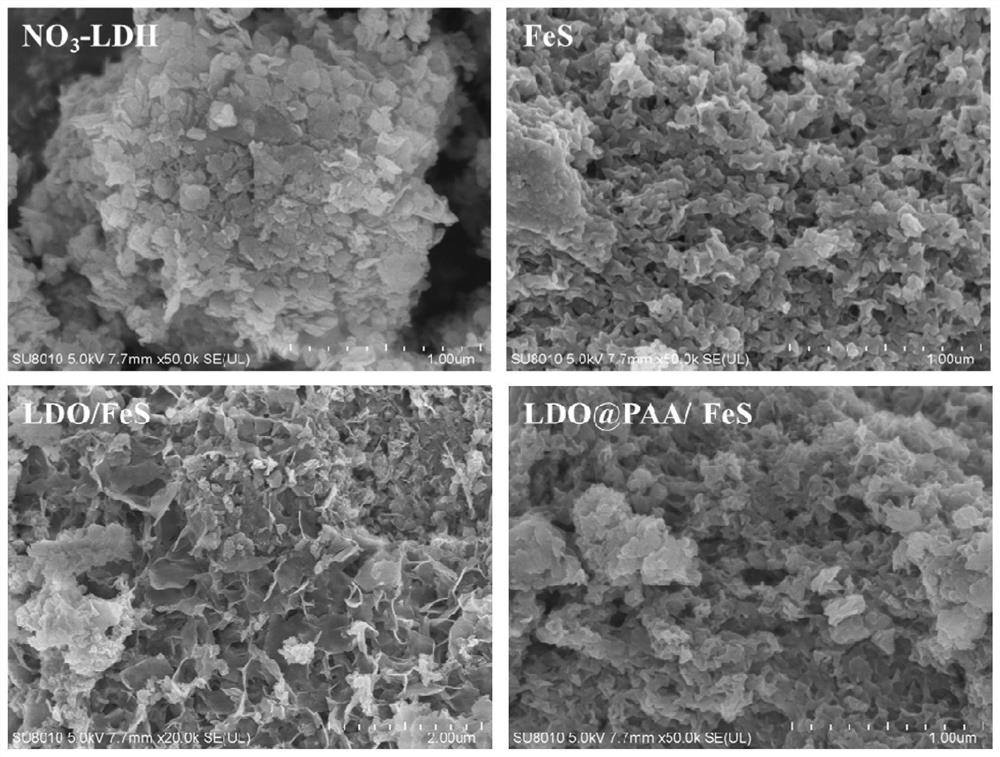

Embodiment 1

[0052] 0.75mol / LMg 2+ with 0.25mol / LAl 3+ Composition A mixed solution, 1.5mol / L NaOH and 1mol / L NaOH 2 CO 3 The mixed solution of B was added dropwise into distilled water with a pH value of about 10, and stirred thoroughly for 2 hours to obtain solution C (containing white precipitate). The obtained solution C was aged in an oven at 70° C. for 24 hours to obtain a carbonate-type layered double hydroxide. Rinse with ethanol and degassed water 1:1, centrifuge at 9000rpm for 3min, repeat several times, and the conductivity of the last washing solution is less than 1000us / cm, and dry in an oven at 70°C to constant weight. Transfer the carbonic acid layered double hydroxide with constant weight into a porcelain crucible and react in a muffle furnace at 600°C for 2 hours. When the temperature of the muffle furnace drops to 200°C, transfer the crucible into a vacuum drying oven in time until the cool down. The ball mill was milled at a speed of 220 rpm for 15 minutes, and the ...

Embodiment 2

[0055] 0.75mol / LMg 2+ with 0.25mol / LAl 3+ Composition A mixed solution, 1.5mol / L NaOH and 1mol / L NaOH 2 CO 3 The mixed solution of B was added dropwise into distilled water with a pH value of about 10, and stirred thoroughly for 2 hours to obtain solution C (containing white precipitate). The obtained solution C was aged in an oven at 70° C. for 24 hours to obtain a carbonate-type layered double hydroxide. Rinse with ethanol and degassed water 1:1, centrifuge at 9000rpm for 3min, repeat several times, and the conductivity of the last washing solution is less than 1000us / cm, and dry in an oven at 70°C to constant weight. Transfer the carbonic acid layered double hydroxide with constant weight into a porcelain crucible and react in a muffle furnace at 600°C for 2 hours. When the temperature of the muffle furnace drops to 200°C, transfer the crucible into a vacuum drying oven in time until the cool down. The ball mill was milled at a speed of 220 rpm for 15 minutes, and the ...

Embodiment 3

[0058] 0.75mol / LMg 2+ with 0.25mol / LAl 3+ Composition A mixed solution, 1.5mol / L NaOH and 1mol / L NaOH 2 CO 3 The mixed solution of B was added dropwise into distilled water with a pH value of about 10, and stirred thoroughly for 2 hours to obtain solution C (containing white precipitate). The obtained solution C was aged in an oven at 70° C. for 24 hours to obtain a carbonate-type layered double hydroxide. Rinse with ethanol and degassed water 1:1, centrifuge at 9000rpm for 3min, repeat several times, and the conductivity of the last washing solution is less than 1000us / cm, and dry in an oven at 70°C to constant weight. Transfer the carbonic acid layered double hydroxide with constant weight into a porcelain crucible and react in a muffle furnace at 600°C for 2 hours. When the temperature of the muffle furnace drops to 200°C, transfer the crucible into a vacuum drying oven in time until the cool down. The ball mill was milled at a speed of 220 rpm for 15 minutes, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com