Hierarchical pore SiO2 microsphere material as well as preparation method and application thereof

A technology of hierarchical pores and microspheres, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problem of increasing the production cost of hierarchical porous SiO2 and restricting the development of hierarchical porous SiO2 materials. , the problem of high raw material prices, to achieve the effect of facilitating industrial expansion of production, slowing down the rate of hydrolysis, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

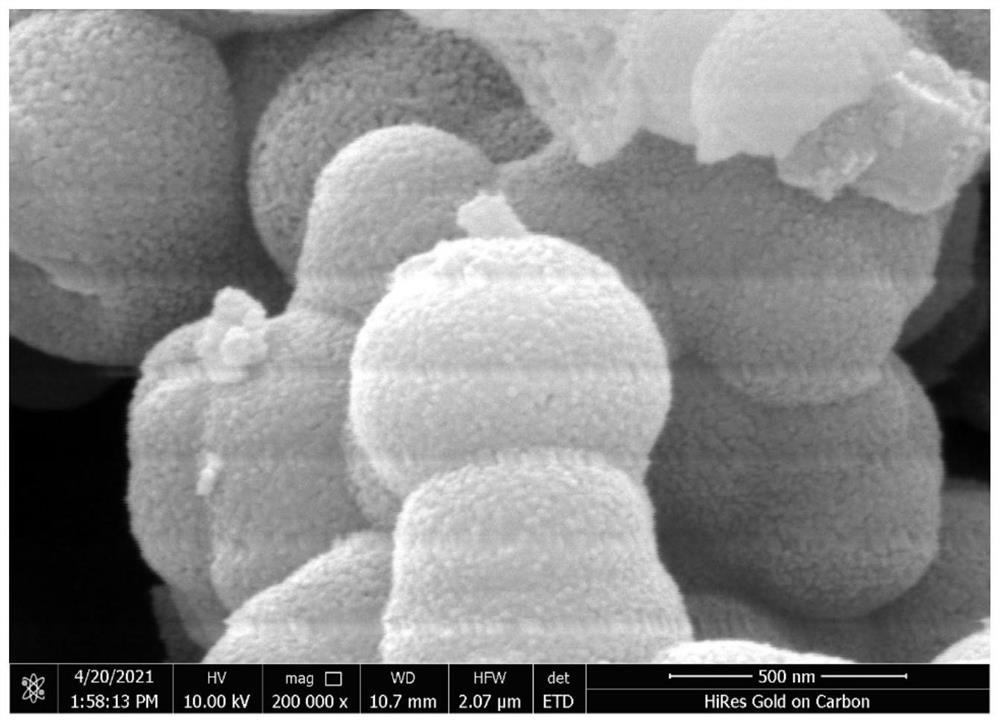

Image

Examples

preparation example Construction

[0044] Preferably, the hierarchical porous SiO of the present invention 2 The preparation method of microsphere material comprises the following steps:

[0045] S1, the collagen and the surfactant extracted from the tanning solid waste (extracted according to the mature existing extraction method technology) are respectively dissolved in distilled water to obtain the solution A containing collagen and the surfactant containing solution B, and fully stir solution A and solution B at room temperature to obtain mixed solution A;

[0046] S2, add catalyst, alcohol solvent and distilled water into solution C into the mixed solution obtained in step S1, stir to make the catalyst fully hydrolyzed, and obtain mixed solution B; when preparing solution C, the consumption ratio of catalyst, alcohol solvent and distilled water is 1 ~3mL:5mL:10mL.

[0047] S3, the solution D prepared by the silicon source precursor, the pore expander and the alcohol solvent is added dropwise to the mixed...

Embodiment 1

[0055] A Hierarchical Porous SiO 2 The preparation method of microsphere material is as follows:

[0056] Weigh 1.3667g (0.015mol) CTAB and dissolve it in 20mL distilled water, weigh 0.5g (0.001mol) collagen and dissolve it in 15mL distilled water, mix the aqueous solution of CTAB and the aqueous solution of collagen, stir under air for 20min, then add Mixed solution of 0.5mL ammonia water, 5mL distilled water and 10mL ethanol, after stirring for 30min, add 2mL tetraethyl orthosilicate and 10mL ethanol mixed solution, continue stirring for 6h to obtain SiO 2 sol, which will subsequently contain SiO 2 After the sol was washed with alcohol, it was transferred to a petri dish, and aged in an oven at 40°C for 24 hours until the sample was dry to promote the non-metallic SiO 2 solution evaporated self-assembled, the dried SiO 2 The solid microspheres were transferred to a corundum crucible, and calcined at a high temperature in a muffle furnace. The temperature was raised to 550...

Embodiment 2

[0061] The hierarchical porous SiO provided by this embodiment 2 The preparation method of the microsphere material is the same as that of Example 1, except that the amount of mesitylene (TMB) in Example 1 is 0.7 g (the mass ratio of TMB:CTAB is 0.5).

[0062] Example 2 Synthesis of Hierarchical Porous SiO 2 Sample N 2 Adsorption-desorption isotherms and pore size distribution diagrams are shown in Figure 4 shown, from Figure 4 It can be seen that the synthesized SiO 2 It has a wide range of pore distribution (1.9-110nm), and the average pore size of the sample calculated by the BJH method is mainly concentrated at 4.6nm. According to the IUPAC classification, the N of the synthetic sample 2 The adsorption and desorption isotherms are type IV isotherms, and have a H2 hysteresis loop, which represents the mesoporous structure in the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com