MarkIII type polycarbosilane and preparation method thereof

A polycarbosilane and polysilane technology, applied in the field of MarkIII type polycarbosilane and its preparation, can solve the problems of unfavorable product performance uniformity, uneven heat transfer in the reaction system, high environmental requirements, and avoid toxicity and environmental pollution. , High synthesis yield, uniform heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

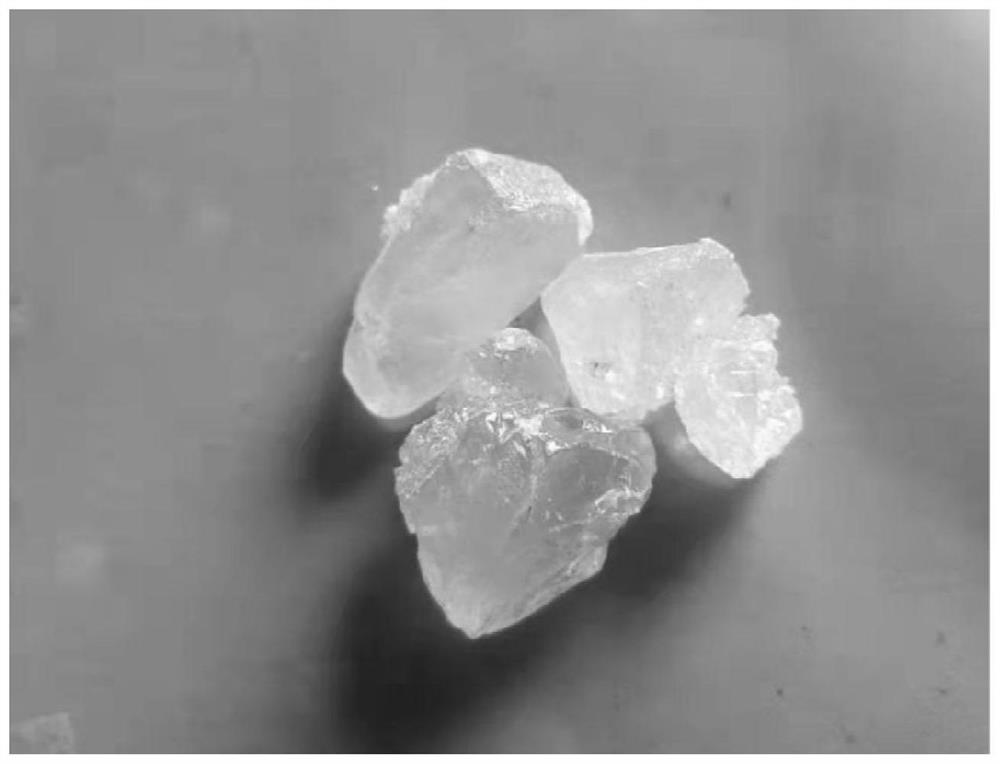

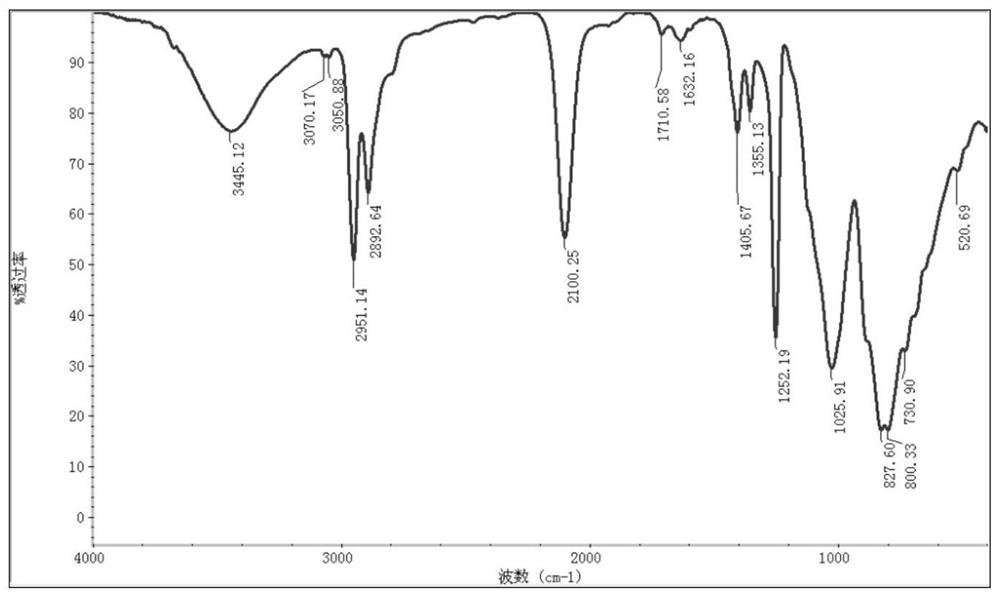

Image

Examples

Embodiment 1

[0030] 1. Put diphenylsilanediol and boric acid in a molar ratio of 3:2 into a metal reaction kettle with n-butyl ether added in advance, blow nitrogen, start stirring, heat up to 90°C, carry out reflux reaction for 15 hours, and then close the reflux. Reaction by-product water and solvent n-butyl ether were distilled off, the temperature was raised to 300° C., kept for 1 hour, and the temperature was lowered to obtain polyborondiphenylsiloxane.

[0031] 2. Add the polydimethylsilane powder into the metal reaction kettle, vacuumize the reaction kettle and fill it with nitrogen, repeat at least three times, and finally keep the nitrogen flow at normal pressure, then start stirring, raise the temperature of the system to 400°C, keep it for 2 hours, and get Pyrolysis product liquid polysilane.

[0032] 3. Add polyborondiphenylsiloxane to liquid polysilane at a ratio of 2% by weight, raise the temperature to 350°C in an inert atmosphere, keep it warm for 6 hours, and then cool dow...

Embodiment 2

[0034] 1. Put diphenylsilanediol and boric acid in a molar ratio of 3:2 into the reaction kettle with n-butyl ether added in advance, blow nitrogen, start stirring, heat up to 95°C, carry out reflux reaction for 18 hours, then close the reflux, and distill Remove the reaction by-product water and the solvent n-butyl ether, raise the temperature to 350° C., keep it warm for 1 hour, and cool down to obtain polyboron diphenylsiloxane.

[0035] 2. Add polydimethylsilane powder into the reaction kettle, vacuumize and fill the reaction kettle with nitrogen, repeat at least three times, and finally keep the nitrogen flow at normal pressure, then start stirring, raise the temperature of the system to 420°C, keep it warm for 3 hours, and obtain heat The hydrolysis product is liquid polysilane.

[0036] 3. Add polyborondiphenylsiloxane to liquid polysilane in a proportion of 3% by weight, raise the temperature to 360°C in an inert atmosphere, keep it warm for 7 hours, and then cool down...

Embodiment 3

[0038] 1. Put diphenylsilanediol and boric acid in a molar ratio of 3:2 into the reaction kettle with n-butyl ether added in advance, blow nitrogen, start stirring, heat up to 100°C, carry out reflux reaction for 20 hours, then close the reflux, and distill Remove the reaction by-product water and the solvent n-butyl ether, raise the temperature to 350° C., keep it under vacuum for 1 hour, and cool down to obtain polyborondiphenylsiloxane.

[0039] 2. Add the polydimethylsilane powder into the reaction kettle, vacuumize the reaction kettle and fill it with nitrogen, repeat at least three times, and finally keep the nitrogen flow at normal pressure, then start stirring, raise the temperature of the system to 420°C, keep it for 2 hours, and get the heat The hydrolysis product is liquid polysilane.

[0040]3. Add polyborondiphenylsiloxane to liquid polysilane at a ratio of 3% by weight, raise the temperature to 370°C in an inert atmosphere, keep it warm for 6 hours, and then lowe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap