Methanation system and method for solar thermochemical cycle hydrogen production

A thermochemical cycle, solar thermal technology, applied in chemical instruments and methods, biochemical equipment and methods, oxygen/ozone/oxide/hydroxide, etc., can solve the problem of hindering hydrogen generation, secondary radiation loss, affecting reaction speed and other issues, to achieve the effect of saving storage and transportation costs, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] In order to make the object, technical solution and advantages of the present invention clearer, the detailed working conditions of the present invention will be further described below in conjunction with the accompanying drawings.

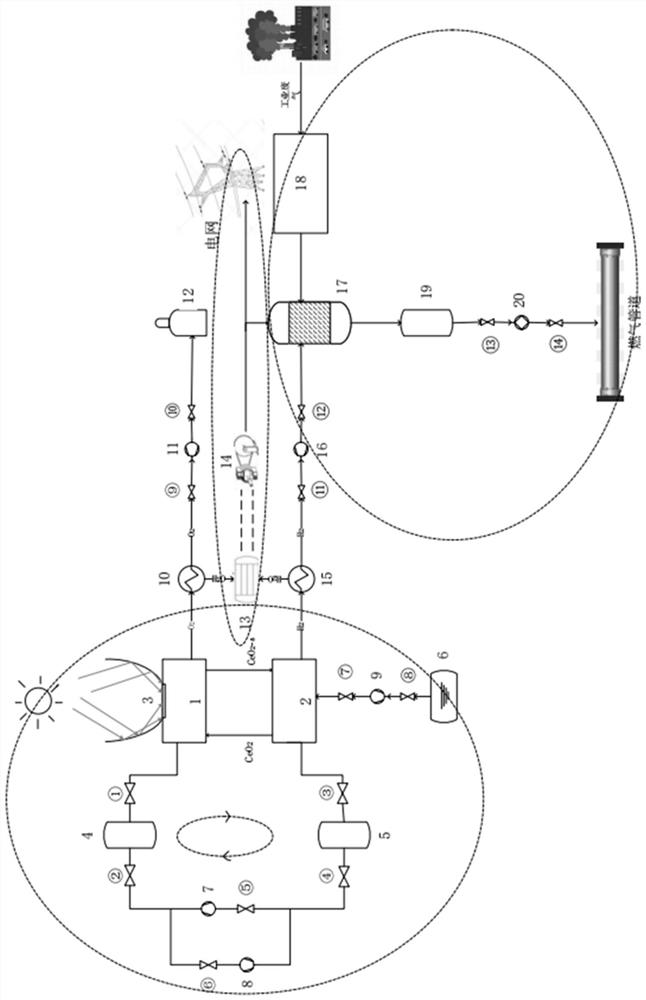

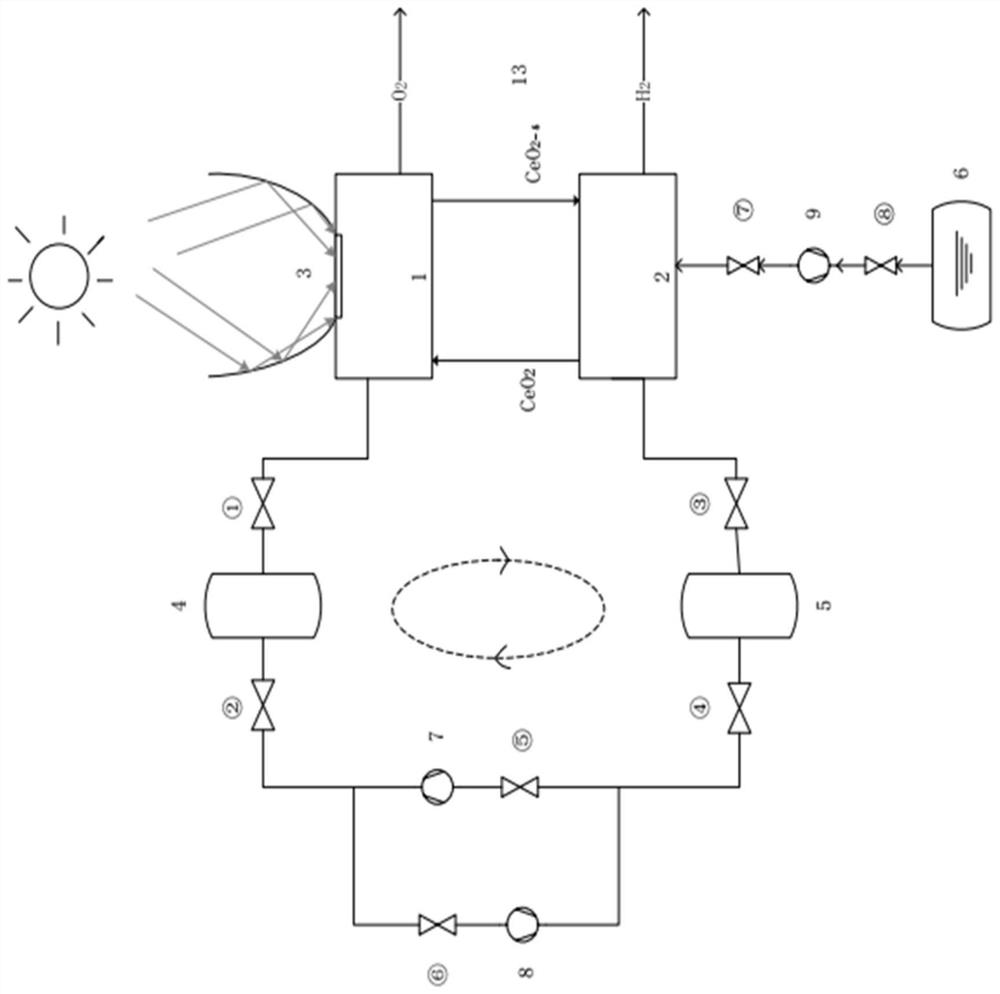

[0069] Such as figure 1 As shown, the methanation system for solar thermochemical cycle hydrogen production provided by the present invention includes a thermochemical cycle hydrogen production module, a high-temperature gas waste heat recovery module and a biomethane module.

[0070] The thermochemical cycle hydrogen production module includes: reduction reactor 1; oxidation reactor 2; solar heat collector 3; first heat storage bottle 4; second heat storage bottle 5; water tank 6; , 9, 11 and high temperature oxygen heat exchanger 10, high temperature hydrogen heat exchanger 15.

[0071] The cerium oxide is added into the reduction reactor, and the reduction reactor absorbs solar energy to provide a high-temperature environment to decomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com