Catalyst for water electrolysis hydrogen production system and preparation method thereof

A hydrogen production system and catalyst technology, which is applied in the field of electrolysis of water, can solve the problems of catalyst structure change, influence on catalytic performance, poor dispersion, etc., and achieve improved stability, improved stability and hydrogen production activity, and excellent electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

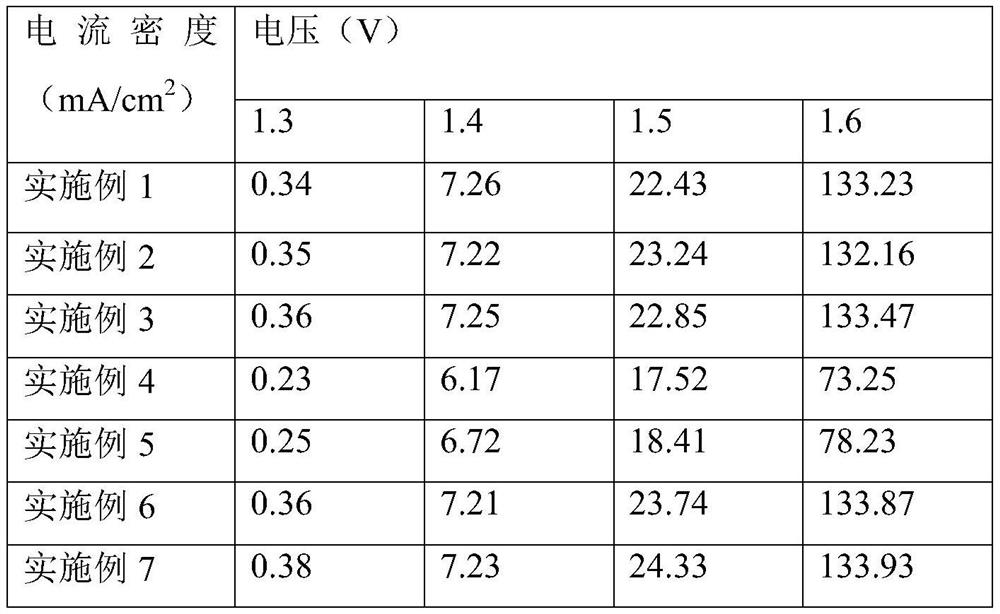

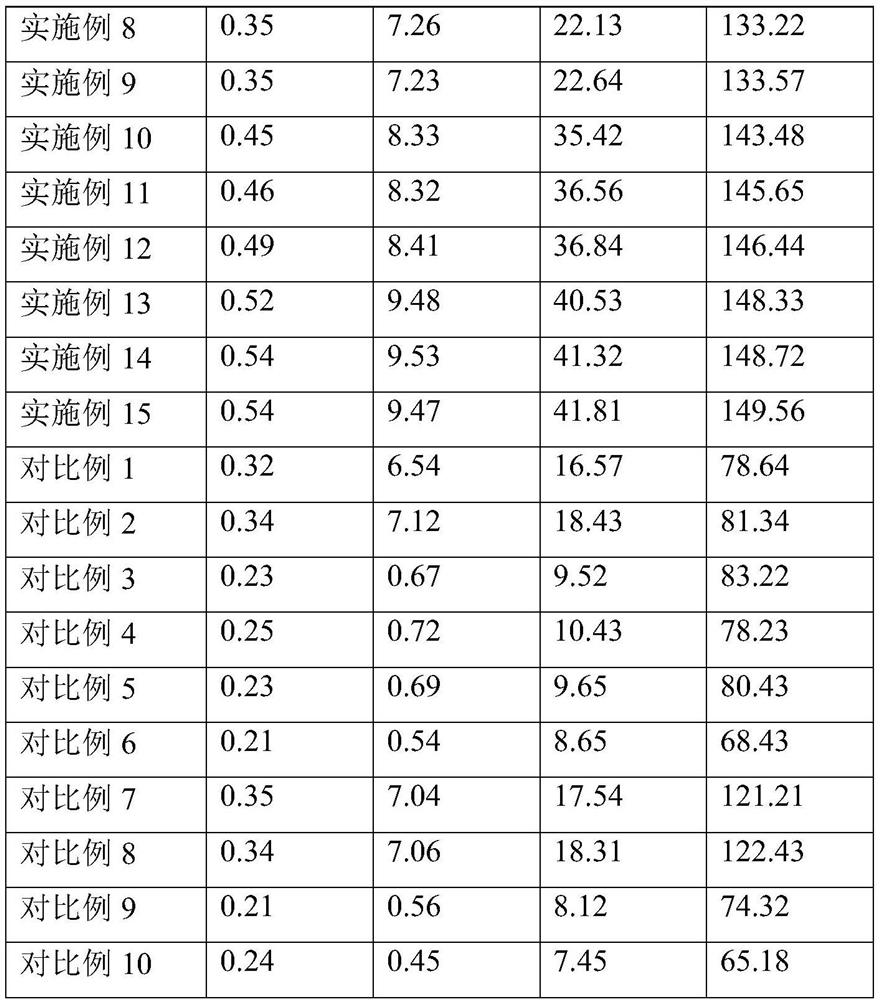

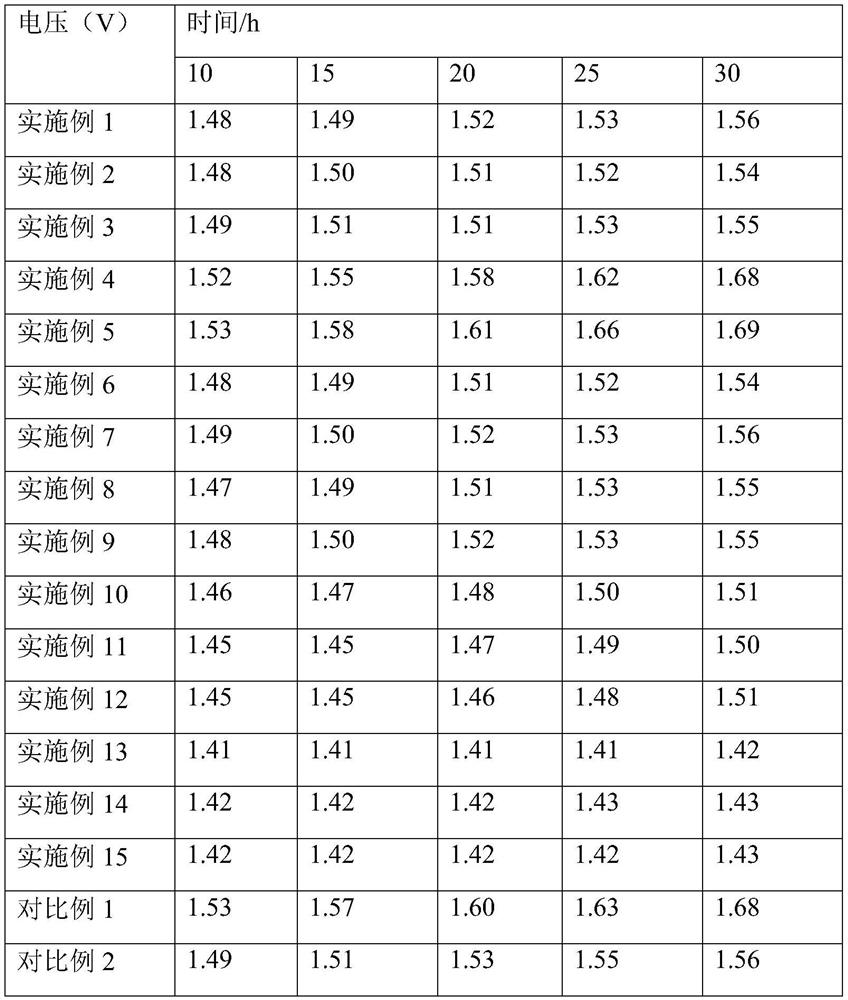

Examples

preparation example 1-3

[0038] In Preparation Example 1-3, carbon nanotubes were selected from Hebei Moyu Chemical Co., Ltd., model CN2020; PMMA was selected from Dongguan Huaxinfa Plastic Raw Material Co., Ltd., model CLEAR011; polyacrylonitrile was selected from Dacheng County Boyang Thermal Insulation Materials Sales Department, the article number is 9000-1, the length is 6mm.

preparation example 1

[0039] Preparation Example 1: Place 0.2kg of carbon nanotubes in 5kg of ethanol and disperse them ultrasonically for 25 minutes with a power of 200w to obtain a suspension. Add 3kg of PMMA and 0.9kg of polyacrylonitrile mass fraction to 1% dimethylamide solution to Ultrasonic dispersion with 200w power for 10min, heat up to 80°C, under nitrogen atmosphere, heat up to 350°C at a rate of 5°C / min, calcinate at 350°C for 2.5h, then heat up for 30min, bake at 750°C for 2.5h, cool to room temperature to prepare a porous carbon material.

preparation example 2

[0040] Preparation example 2: 0.25 kg of carbon nanotubes are placed in 6 kg of ethanol, ultrasonically dispersed for 30 min with a power of 250 w to obtain a suspension, and 3.5 kg of PMMA and 1 kg of polyacrylonitrile mass fraction are added to a dimethylamide solution with a mass fraction of 1%. Ultrasonic dispersion with 250w power for 20min, heating up to 90°C, under nitrogen atmosphere, heating up to 380°C at a rate of 5°C / min, calcining at 380°C for 2h, then heating up for 30min, calcining at 800°C for 2h, cooling to room temperature , to produce porous carbon materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com