Long fiber reinforced polyaryletherketone composite material and preparation method thereof

A technology of polyaryletherketone and composite materials, which is applied in the field of preparation of long-fiber reinforced polyaryletherketone composite materials and its preparation, can solve the problems of high price and achieve excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

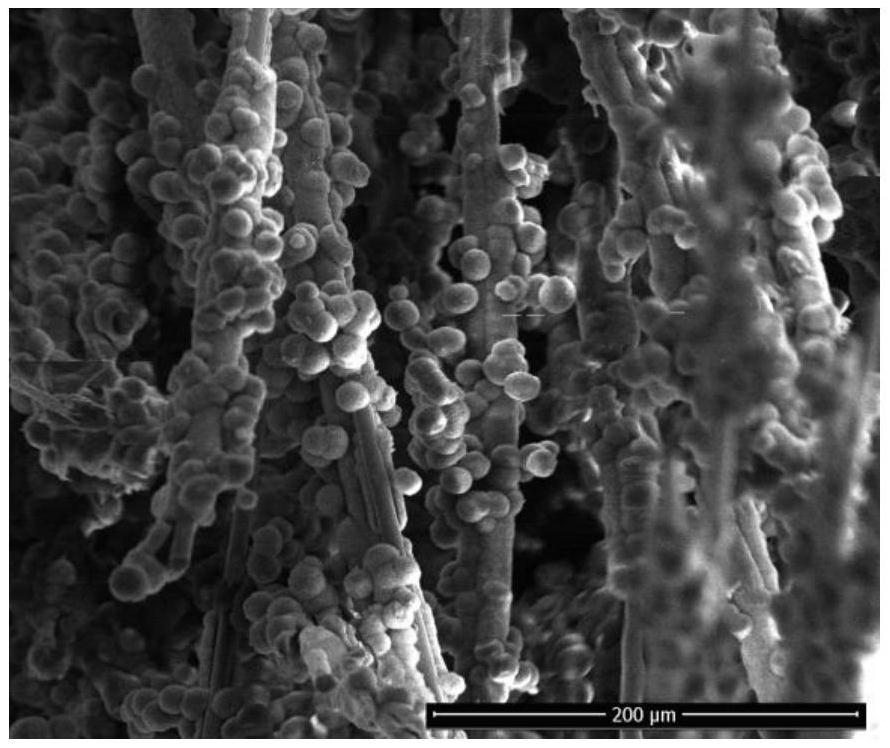

Image

Examples

Embodiment 1

[0038] S1: Fiber pretreatment process can be carried out according to the following examples:

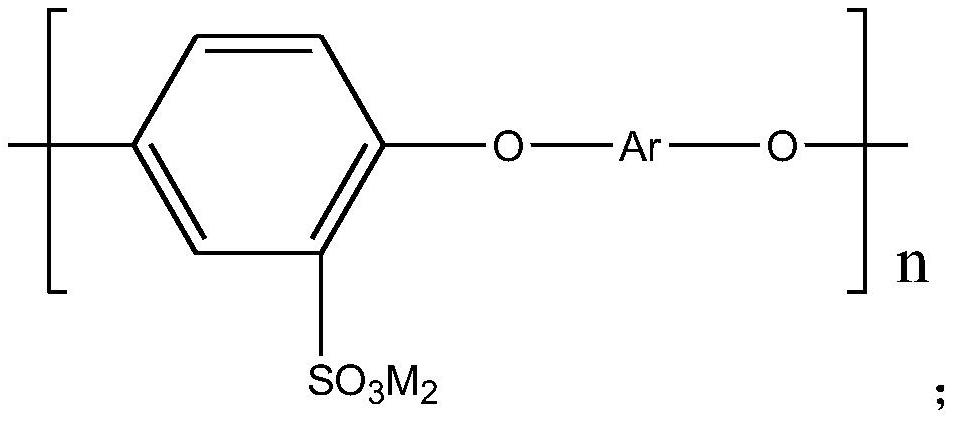

[0039] Weigh 1.5 g of polyetheretherketone resin (wherein Ar is benzene-ketone-benzene, M is sodium ion) with a sulfonation degree of 50%, add 150 ml of DMF, stir and dissolve to obtain a uniform solution. Add 90g of 2mm long-cut glass fibers into the solution, stir for 15min, add the reaction system to 500mL of 5% sodium carbonate solution, soak for 12 hours, filter, and dry at 120°C for 12 hours to obtain the treated long fibers.

[0040] S2: Polyether ether ketone polymerization process and composite can be implemented according to the following examples:

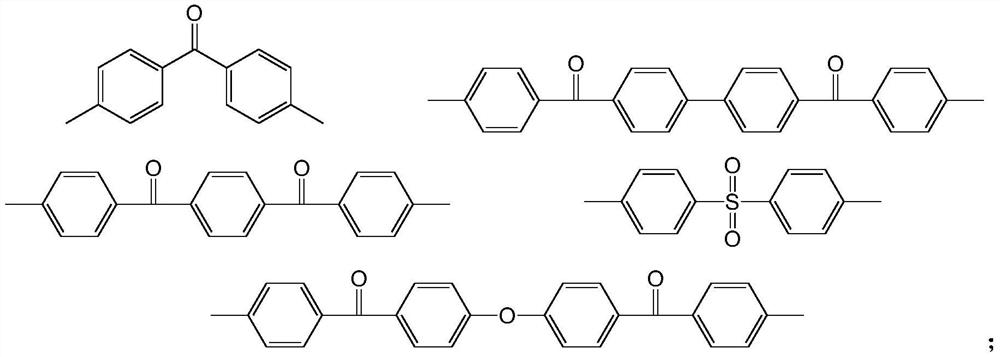

[0041] Add 115 g of molten diphenyl sulfone to a reaction flask with nitrogen gas, add 43.82 g of 4,4'-difluorodiphenyl ketone into a three-necked flask equipped with mechanical stirring and a thermometer, protect with nitrogen, and heat to 160 ° C. Add 25.44g of anhydrous sodium carbonate, then heat to 165°C, add 22.00g of hyd...

Embodiment 2

[0043] The glass fiber in Example 1 was replaced with carbon fiber T700.

Embodiment 3

[0045] The amount of treated glass fiber added in Example 1 was 17.3 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com