Lithium squarate and preparation method and application thereof

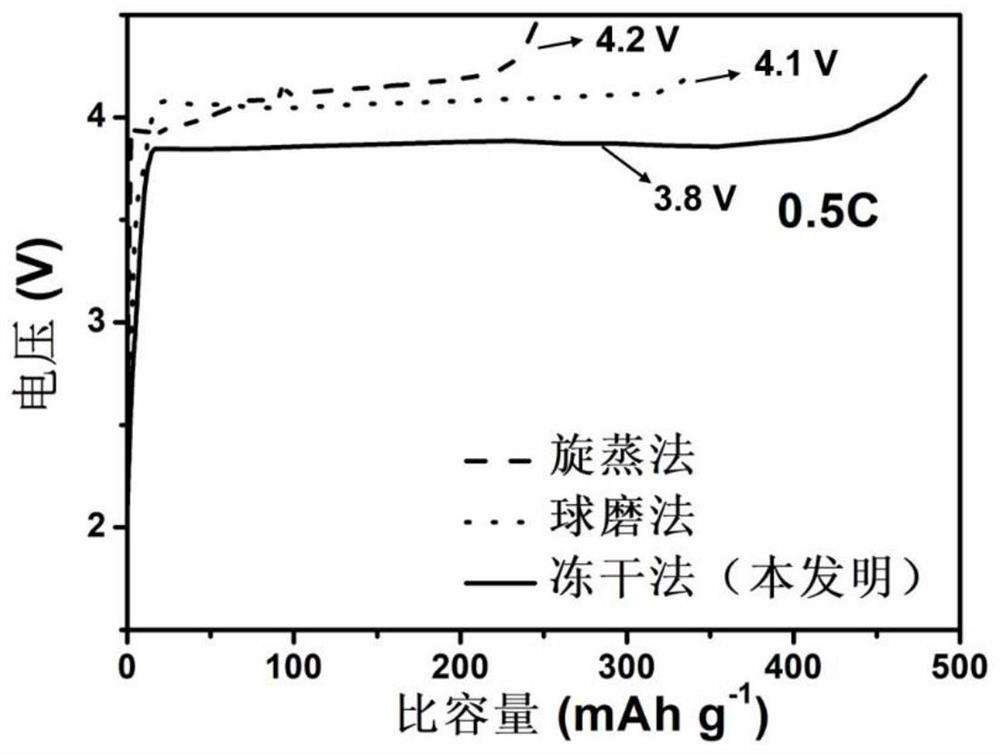

A technology of lithium squaraine and squaraine, applied in the field of energy storage, can solve the problems of low electrochemical performance, prone to agglomeration, cumbersome preparation process of lithium squaraine, etc., and achieves a simple preparation process, low cost, and improved electrochemical activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

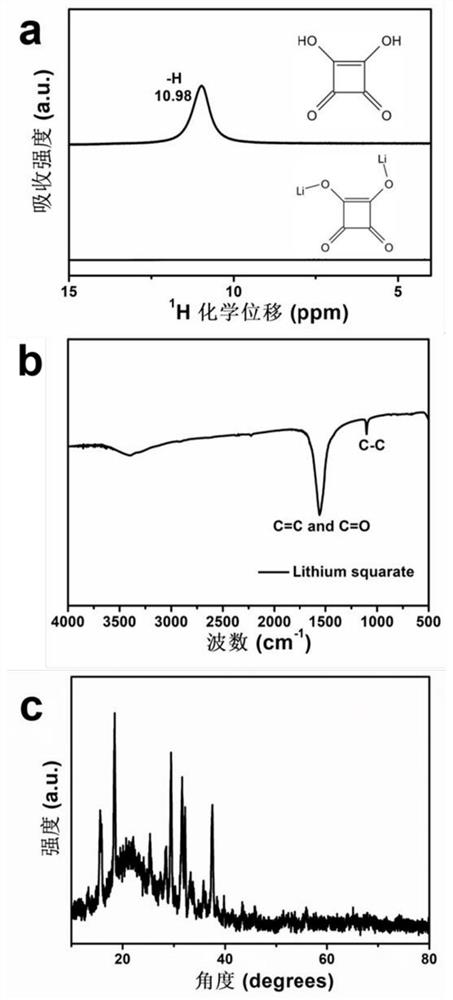

[0059] Synthesis Example 1 prepared lithium squarylium by freezing in a refrigerator. The specific steps were as follows: 0.5800 g of squarylium and 0.3695 g of lithium carbonate were respectively dissolved in 50 ml of deionized water, and the aqueous solution of lithium carbonate was slowly added into the aqueous solution of squarylium in a water bath at 60 ° C. Stirring was maintained for 2 h after the addition was complete.

[0060] The solution was rotary evaporated at 60° C. until all the water was evaporated to obtain a white powder. Then the white powder was washed 3 times with absolute ethanol to remove excess squarylium therein to obtain a pure phase of lithium squarylium.

[0061] The pure phase of the above-mentioned lithium squarylate was dissolved in 20 ml of deionized water, quick-frozen in a freezer for 6 hours, and the quick-frozen solution was freeze-dried at -40° C. for 48 hours to obtain lithium squarylate.

Synthetic example 2

[0063] Synthesis Example 2: Lithium squarylium was prepared by quick-freezing with liquid nitrogen. The specific steps were as follows: 0.5800 g of squarylium and 0.3695 g of lithium carbonate were dissolved in 50 ml of deionized water respectively, and the aqueous solution of lithium carbonate was slowly added into the aqueous solution of squarylium in a water bath at 60 ° C. Stirring was maintained for 2 h after the addition was complete.

[0064] The solution was rotary evaporated at 60° C. until all the water was evaporated to obtain a white powder. Then the white powder was washed 3 times with absolute ethanol to remove excess squarylium therein to obtain a pure phase of lithium squarylium.

[0065] The pure phase of the above lithium squarylate was dissolved in 20 ml of deionized water, quick-frozen in liquid nitrogen for 2 minutes, and the quick-frozen solution was freeze-dried at -40° C. for 48 hours to obtain lithium squarylate.

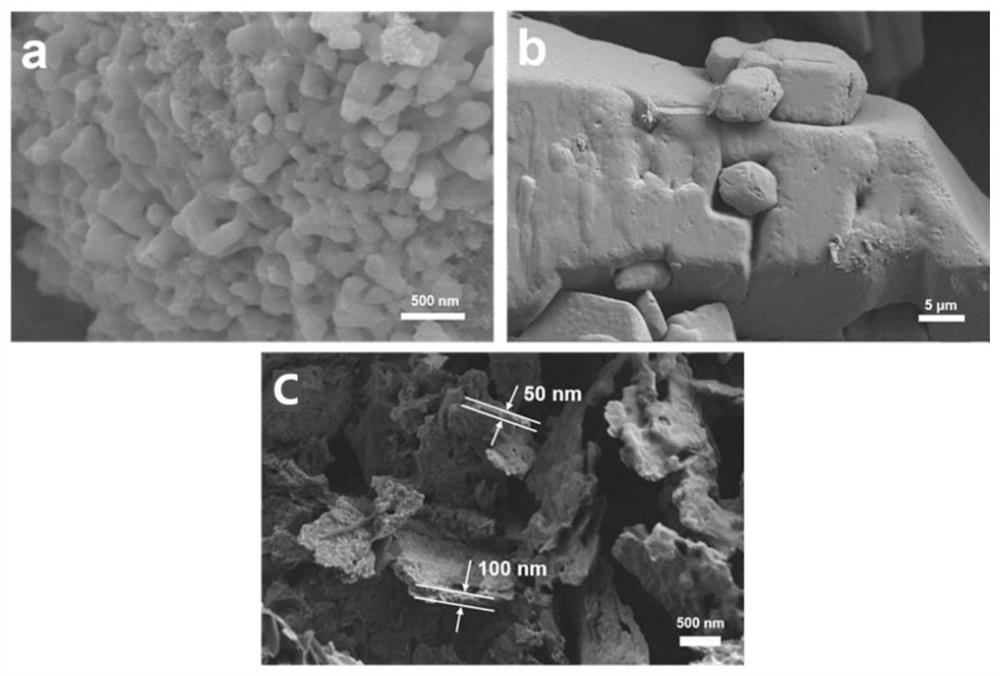

[0066] The lithium squarylate materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com