Molybdenum monatomic catalyst and preparation method and application thereof

A catalyst and atomic technology, applied in the direction of textiles and papermaking, electrodes, heating/cooling fabrics, etc., can solve the problem that the research on the influence of reduction performance is not very deep, so as to improve the electrocatalytic nitrogen reduction rate, improve the charge density, and improve the charge distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

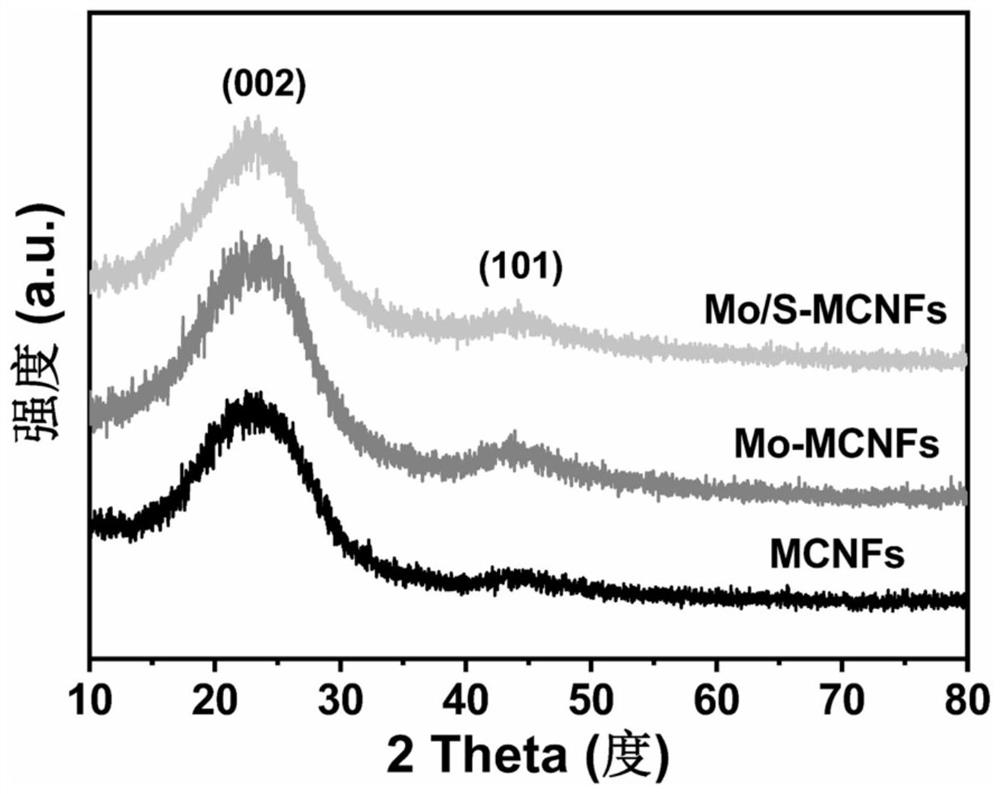

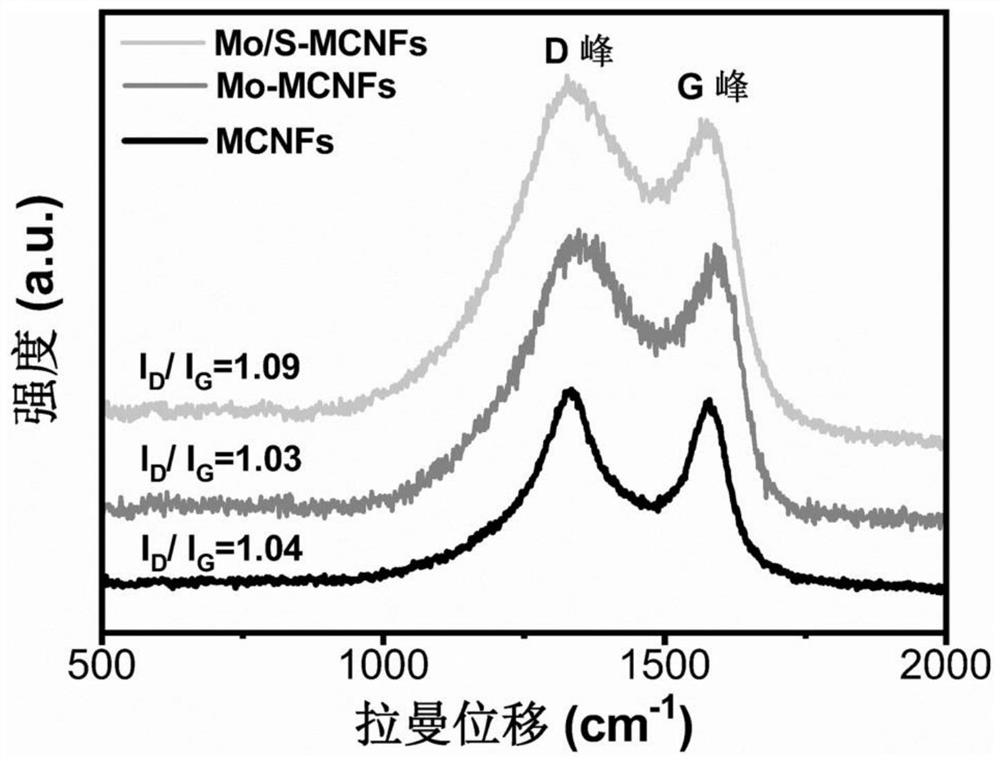

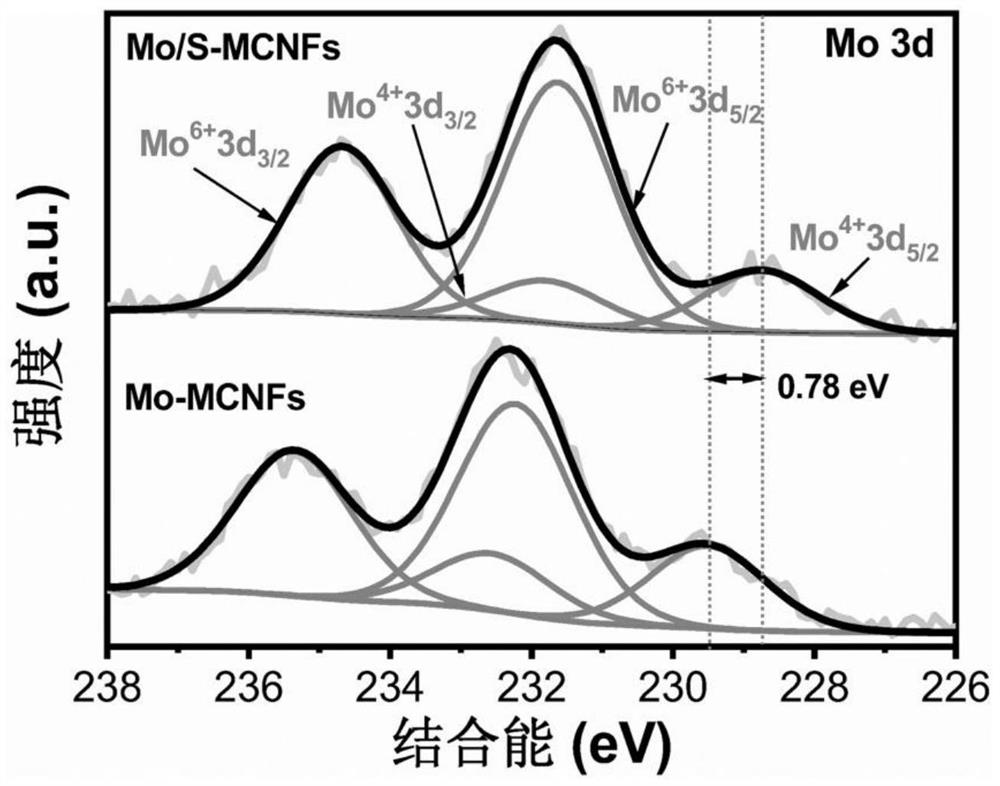

[0030] The invention provides a method for preparing a molybdenum single-atom catalyst for nitrogen reduction. The invention uses Mo-based catalysts as the research object of nitrogen reduction. Since Mo belongs to one of the key elements for nitrogen fixation by nitrogenase, it has a good imitation effect and can Effectively improve the performance of nitrogen reduction; in addition, through the regulation of the coordination environment around the Mo single atom, the introduction of nitrogen (N) and sulfur (S) heteroatoms can significantly improve the electronic structure around the Mo single atom, thereby improving Its charge density greatly improves its catalytic performance; the multi-channel carbon fiber prepared by electrospinning can significantly increase the contact area between the active center of the catalyst and the reactant, and accelerate the charge transfer and material transport, and finally further improve the electrocatalytic nitrogen. Restored performance. ...

Embodiment 1

[0035] This embodiment provides a synthesis and performance testing process of a molybdenum single-atom catalyst. The specific steps are as follows:

[0036] First dissolve polyacrylonitrile in N,N-dimethylformamide, at this time the mass concentration of polyacrylonitrile is 10%, and stir at room temperature for 12 hours until a uniform white solution is formed, then add polyacrylonitrile Methyl methacrylate. At this time, the mass ratio of polyacrylonitrile to polymethyl methacrylate is 3:4, and it is placed in a constant temperature heating magnetic stirrer at 60°C and continuously stirred until a uniform solution is formed, and then poured into it Ammonium thiomolybdate powder was added so that the mass ratio of the metal molybdenum source to the polyacrylonitrile of the electrospinning solution was 1:10, and stirred again at room temperature for 12 hours until a uniform dark brown solution was formed. Use a 5mL medical syringe to draw a certain amount of the prepared elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com