Methanoic acid hydrogen production catalyst as well as preparation method and application thereof

A catalyst and catalyst carrier technology, applied in the field of hydrogen energy, can solve the problems of high preparation temperature and complicated preparation process, and achieve the effect of mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

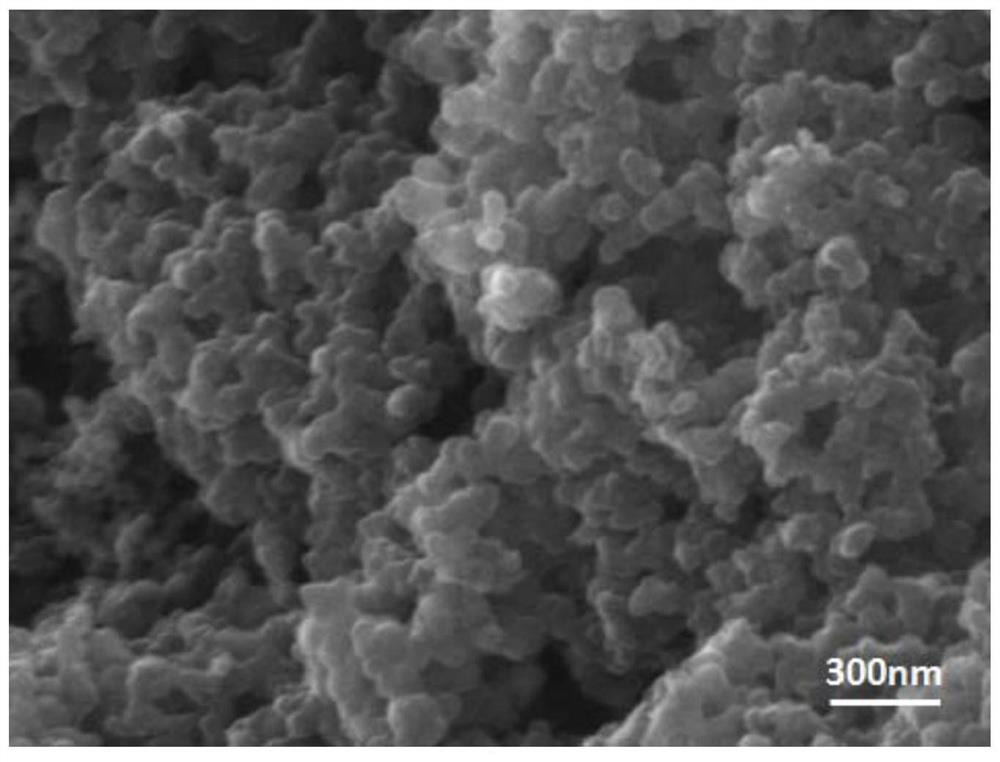

Image

Examples

Embodiment 1

[0044] In this example, a catalyst for hydrogen production from formic acid is prepared, and the specific preparation process is as follows:

[0045] (1) The XC-72R type carbon black of 0.6g, 1.5g boric acid, 2.1g melamine are dissolved in 50ml deionized water, stir 30min to form a uniform suspension, then the suspension is transferred to the hydrothermal reaction kettle, and Hydrothermal treatment was carried out at 180°C for 12 hours in an oven.

[0046] (2) Cool the hydrothermal reaction kettle in step (1) naturally, filter the product therein with a circulating water vacuum pump, wash with deionized water, dry in an oven at 60° C. for 12 hours, and then cool to room temperature.

[0047] (3) The product dried in step (2) was placed in a muffle furnace for heat treatment at 600° C. for 3 h, and then cooled to room temperature to obtain a N, B doped C catalyst support.

[0048] (4) Configure 100ml (0.01mmol / L) aqueous solution of chloropalladic acid, dissolve 0.2g of N, B-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com