A kind of preparation method of mildew-resistant bamboo unit/bamboo product

A technology of bamboo products and bamboo materials, applied in chemical instruments and methods, manufacturing tools, wood treatment, etc., can solve the problems of large loss of mechanical strength, brittle surface, loss of mechanical strength, etc., reduce the difficulty of treatment and improve mildew resistance , maintain a high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The method that present embodiment prepares mildew-resistant bamboo bundle may further comprise the steps:

[0041] Step 1. Obtaining waste water from high-temperature heat treatment of bamboo: collecting waste water from high-temperature heat treatment of bamboo processing bamboo. 150min, during the heat treatment process, continuously spray atomized water into the upper part of the carbonization kiln to maintain a slight positive pressure in the carbonization kiln. Bamboo with a moisture content of 10% produces 0.12kg of bamboo high-temperature heat treatment waste water;

[0042] Step 2. Precipitation of reducing sugar in waste water from high-temperature heat treatment of bamboo: After uniformly mixing liquid A and liquid B, add it to the waste water from high-temperature heat treatment of bamboo collected in step 1, carry out precipitation reaction of reducing sugar, let it stand for 60 minutes to produce precipitation, and take the supernatant to obtain Wastewate...

Embodiment 2

[0047] The method for preparing mildew-resistant bamboo bundles in this embodiment is the same as that in Example 1, except that the specific process of step 3 is different. Step 3 of present embodiment 3 is: wastewater a oxidation treatment: using UV ultraviolet radiation Carry out oxidation treatment according to the waste water a obtained in the step 2, generate quinones in the waste water a, obtain the mildew-resistant impregnating liquid; 6cm, stirring 4 times per minute, the lamp tube is 10cm away from the liquid surface; the power of the high-pressure mercury lamp is 1kW; 80% of the high-pressure mercury lamp band is the ultraviolet band, wherein UV-A31%, UV-B24%, UV- C25%;

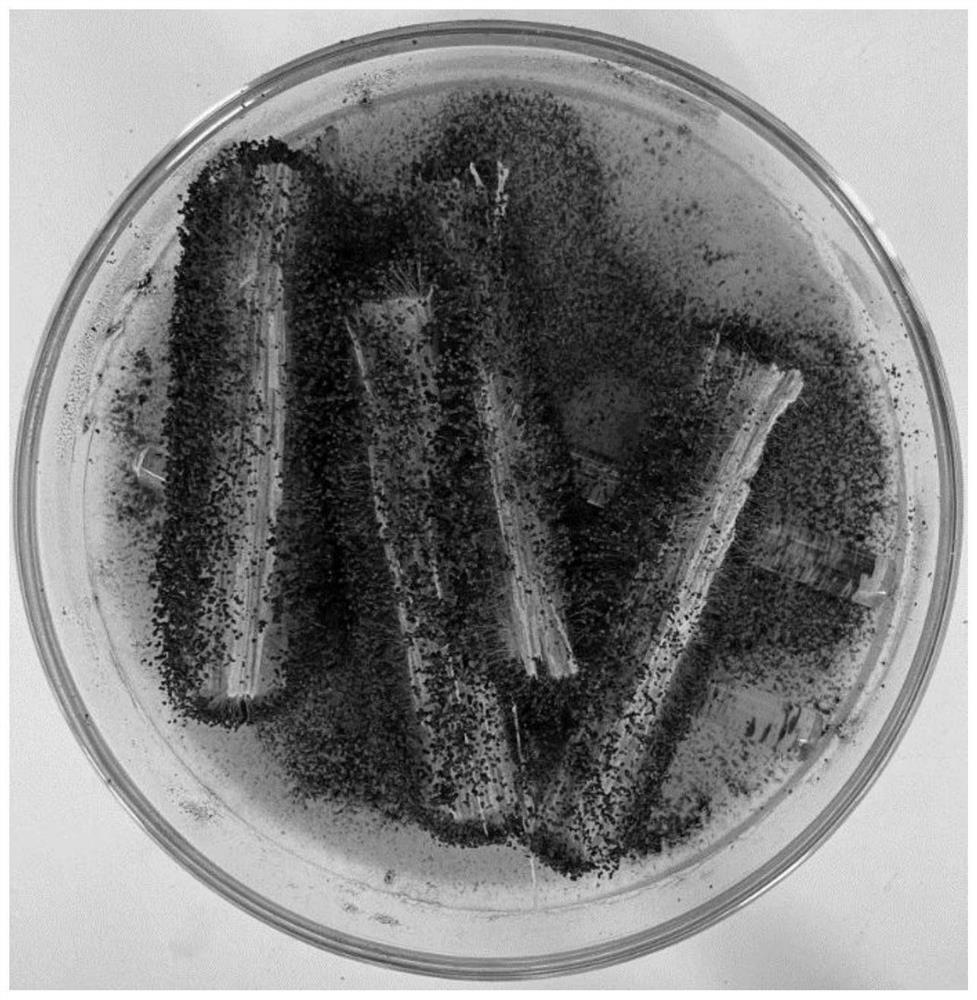

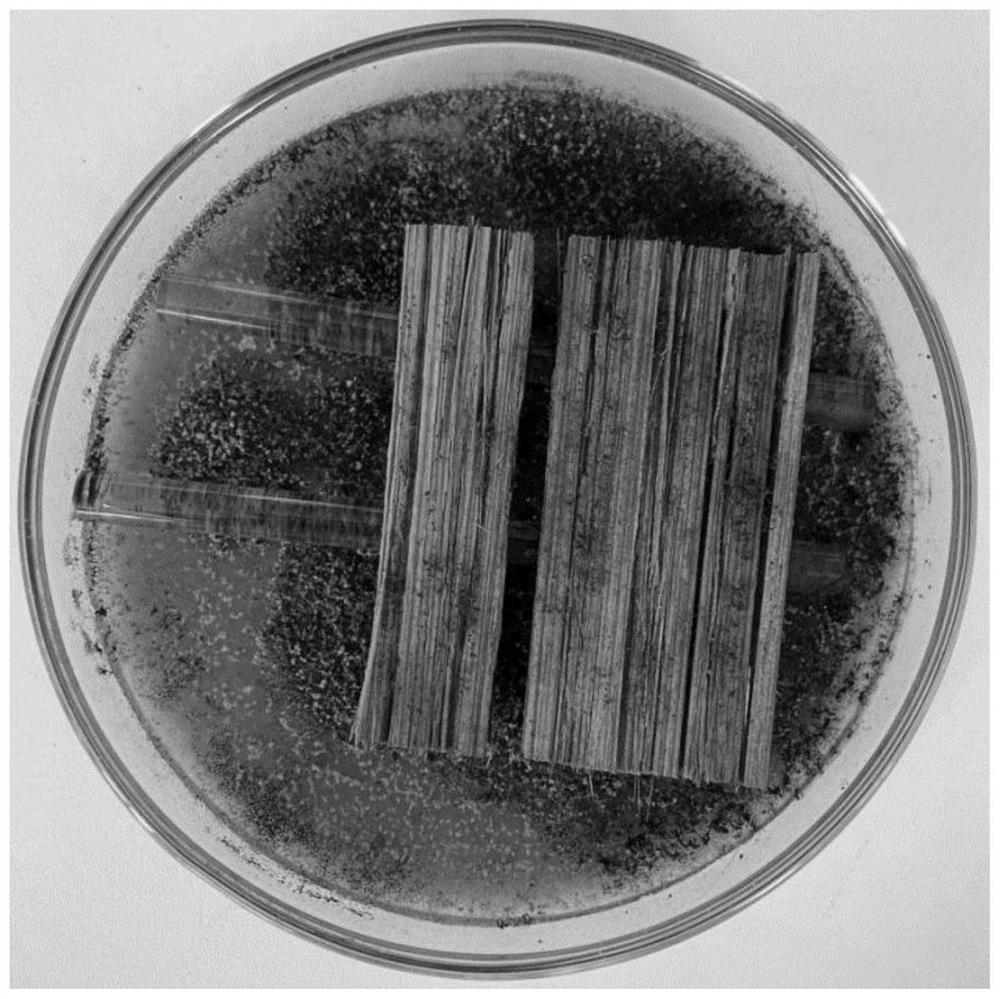

[0048] (1) Bamboo bundle mildew test

[0049] According to the test method in the national standard GB / T 18261-2013 "Test method for the control of wood mold and blue stain by antifungal agents", the mildew resistance of bamboo bundles was determined. Aspergillus niger V. Tiegh, Penicillium citri...

Embodiment 3

[0060] The method that present embodiment prepares mildew-resistant bamboo chip may further comprise the steps:

[0061] Step 1. Obtaining waste water from high-temperature heat treatment of bamboo: collecting waste water from high-temperature heat treatment of bamboo processing bamboo. 200min, during the heat treatment process, continuously spray atomized water into the upper part of the carbonization kiln to maintain a slight positive pressure in the carbonization kiln. Bamboo with a moisture content of 8% produces 0.12kg of bamboo high-temperature heat treatment waste water;

[0062] Step 2, Precipitation of reducing sugar in waste water from high-temperature heat treatment of bamboo: Mix liquid A and liquid B evenly and pour into the waste water from high-temperature heat treatment of bamboo collected in step 1. The volume ratio of the liquid and the B liquid is 0.8:2, and the total addition of the A liquid and the B liquid is 0.5% of the quality of the waste water from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com