Method for preparing triclopyr butoxyethyl ester by aqueous phase synthesis method

A technology of triclosan butoxyethyl acetate and triclosan, which is applied in the field of preparing triclosan butoxyethyl by an aqueous synthesis method, can solve the problems of incomplete contact of reactants, soil erosion, etc. Problems such as poor adsorption capacity and difficulty in large-scale preparation can achieve the effects of reducing pesticide scouring, reducing three wastes and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

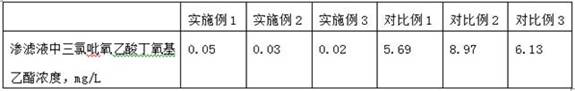

Examples

Embodiment 1

[0031] A method for preparing triclopyroxyethyl butoxyethyl ester by an aqueous phase synthesis method, specifically:

[0032] 1. Add 20kg deionized water, 5kg triclopyridinate sodium, 2.5kg chloroacetyl chloride, 0.1kg sodium lauryl sulfate, 0.2kg ethanol to the reactor at one time, and then control the temperature of the reactor to 40°C , the stirring speed of the reactor was controlled to 100rpm, after stirring for 30 minutes, the stirring was stopped, the temperature of the reactor was controlled to -5°C, and after standing for 20 minutes, the temperature of the reactor was gradually increased to 40°C, and the heating rate was controlled to be 2 °C / min;

[0033] 2. After the temperature of the reactor rises to 40°C, control the stirring speed of the reactor to 150rpm, add 0.15kg of cross-linking catalyst and 0.05kg of sodium hydroxide to the reactor, keep it at 40°C for 45 minutes, and then stop stirring ;

[0034] The preparation method of the cross-linking catalyst is sp...

Embodiment 2

[0040] A method for preparing triclopyroxyethyl butoxyethyl ester by an aqueous phase synthesis method, specifically:

[0041] 1. Add 22kg deionized water, 5.2kg sodium triclopyridinate, 2.6kg chloroacetyl chloride, 0.1kg sodium lauryl sulfate, 0.2kg ethanol to the reactor at one time, and then control the temperature of the reactor to 42 ℃, the stirring speed of the reactor was controlled to 105rpm, after stirring for 32min, the stirring was stopped, the temperature of the reactor was controlled to -7℃, and after standing for 22min, the temperature of the reactor was gradually raised to 42℃, and the heating rate was controlled to be 2.2°C / min;

[0042] 2. After the temperature of the reaction kettle rises to 42°C, control the stirring speed of the reaction kettle to 155rpm, add 0.17kg of cross-linking catalyst and 0.05kg of sodium hydroxide to the reaction kettle, keep it at 42°C for 47 minutes, and then stop stirring ;

[0043] The preparation method of the cross-linking c...

Embodiment 3

[0049] A method for preparing triclopyroxyethyl butoxyethyl ester by an aqueous phase synthesis method, specifically:

[0050] 1. Add 25kg deionized water, 5.5kg sodium triclopyridinate, 2.8kg chloroacetyl chloride, 0.2kg sodium lauryl sulfate, 0.3kg ethanol to the reactor at one time, and then control the temperature of the reactor to 45 ℃, the stirring speed of the reactor was controlled to 110rpm, after stirring for 35min, the stirring was stopped, the temperature of the reactor was controlled to -10℃, and after standing for 25min, the temperature of the reactor was gradually increased to 45℃, and the heating rate was controlled to be 2.5℃ / min;

[0051] 2. After the temperature of the reaction kettle rises to 45°C, control the stirring speed of the reaction kettle to 160rpm, add 0.18kg of cross-linking catalyst and 0.06kg of sodium hydroxide to the reaction kettle, keep the temperature at 45°C for 50min, and then stop stirring ;

[0052] The preparation method of the cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com