Continuous regulation and control method of carbon nitride energy band structure and method for preparing hydrogen peroxide through photocatalysis

A technology of energy band structure and carbon nitride, applied in hydrogen peroxide, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of insufficient valence band oxidation driving force, unfavorable separation and purification of products, and slow water oxidation rate, etc. problems, to achieve the effect of easy on-site amplification test, strong operability, and increased valence band potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

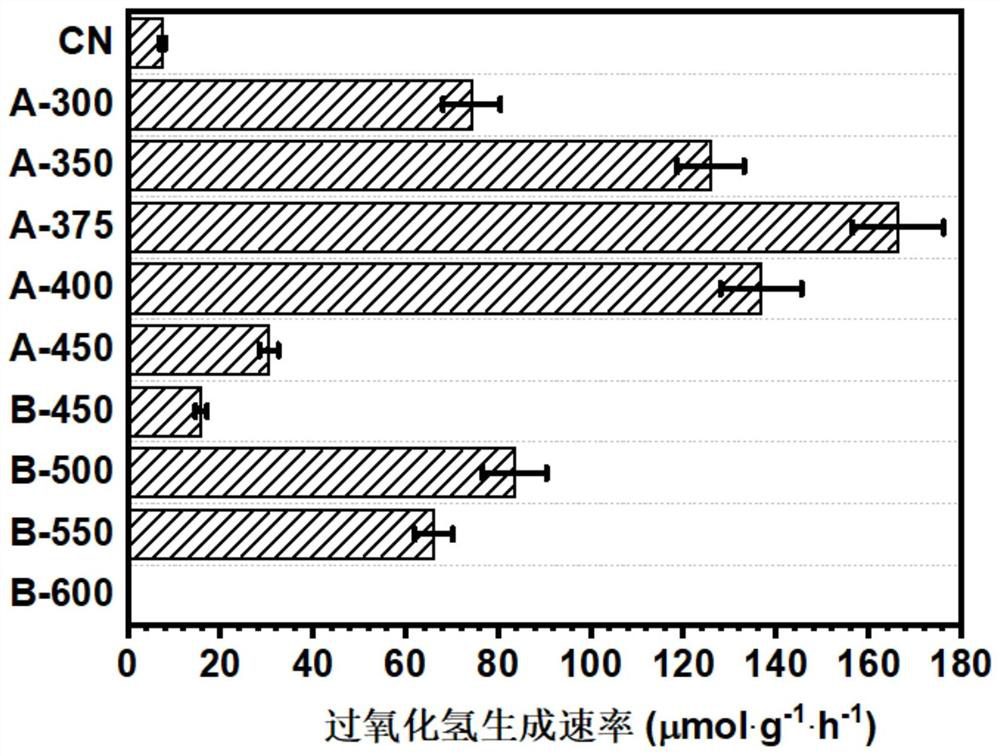

[0077] The invention provides a method for preparing carbon nitride with adjustable energy band structure, comprising the following steps:

[0078] 1) After mixing sodium borohydride or borax with carbon nitride, heat treatment is carried out under a nitrogen atmosphere to obtain a modified carbon nitride with an adjusted energy band structure.

[0079] In the present invention, the carbon nitride includes bulk carbon nitride.

[0080] The present invention is a complete and refined overall preparation process, which can better ensure the continuous adjustability and controllability of carbon nitride, ensure the morphology, structure and parameters of carbon nitride after regulation, and improve the subsequent photocatalytic performance. The above-mentioned bulk nitrogen Carbonized carbon can be specifically prepared by the following steps:

[0081] After calcining nitrogen-containing organic matter, bulk carbon nitride is obtained;

[0082] In the present invention, the nit...

Embodiment 1

[0118] Preparation method of carbon nitride with adjustable energy band structure

[0119] (1) Preparation of bulk carbon nitride

[0120] Weigh 10g of melamine, grind it, put it into a crucible, cover it, put the crucible into a muffle furnace, heat up to 550°C at a rate of 2°C / min, keep it for 4h, then stop heating, cool naturally, and finally grind fully to get a light yellow color bulk carbon nitride products;

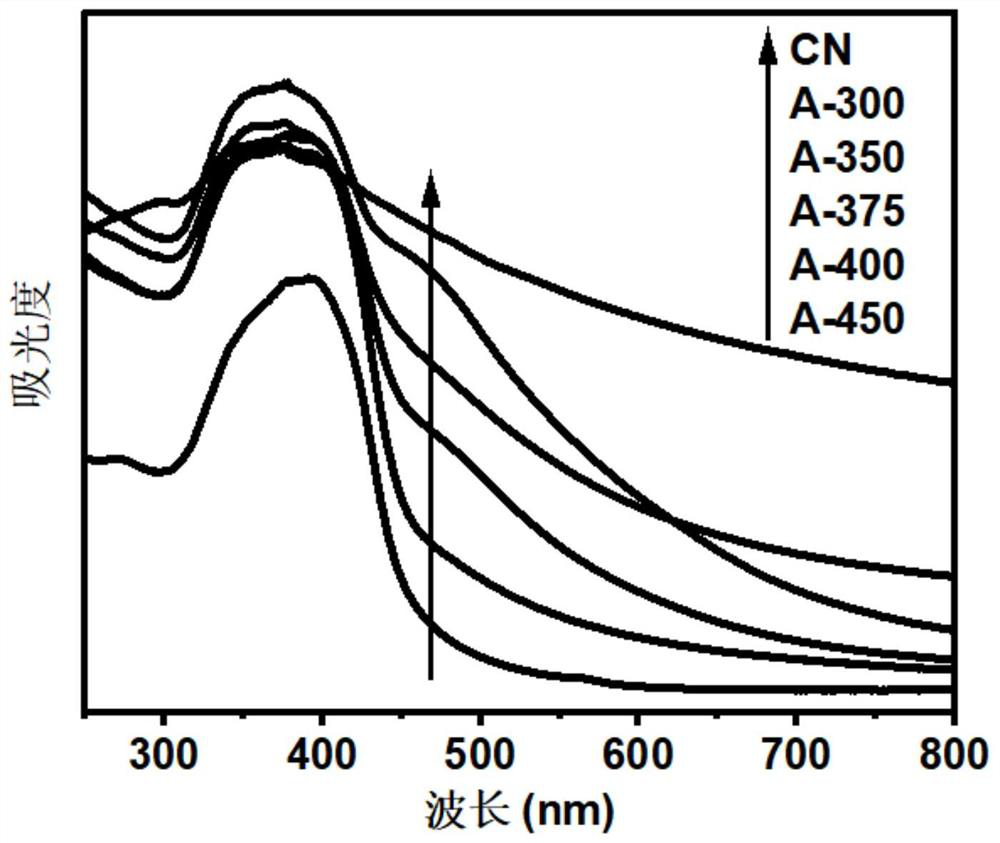

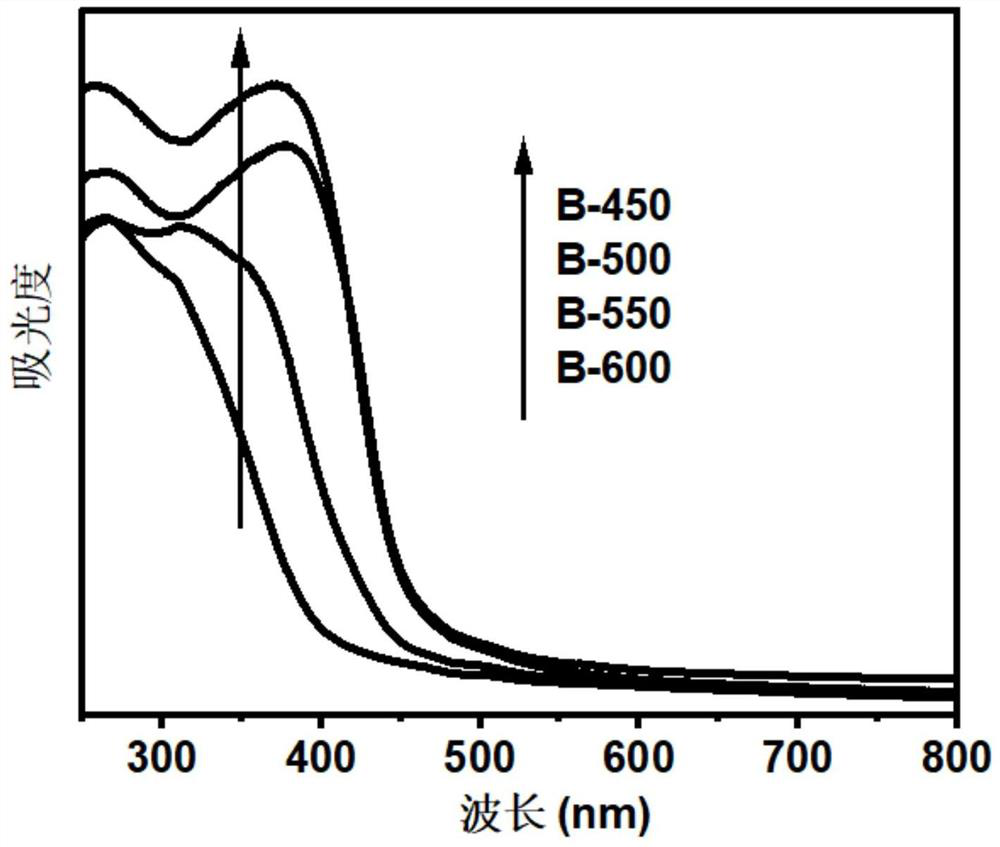

[0121] (2) Preparation of carbon nitride with narrow band gap,

[0122] Mix 1g of the above-mentioned bulk carbon nitride powder with 1g of sodium borohydride, grind evenly, place the mixture in a porcelain boat, and then put it into a tube furnace, control the nitrogen flow rate to 50mL / min, and start heating after nitrogen gas is introduced for 1h , the heating rate is 2°C / min, heated to 300, 350, 375, 400 or 450°C, kept for 4h, then stopped heating, cooled naturally, ground, washed with deionized water three times, dried at 60°C, and finally sodium borohydride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com