Preparation method of cornuside bulk drug

A technology of new glycosides and raw materials of Cornus officinalis, which is applied in the field of biomedicine, can solve the problems of high equipment requirements, high cost, and large equipment investment, and achieve high purity, high yield, and simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

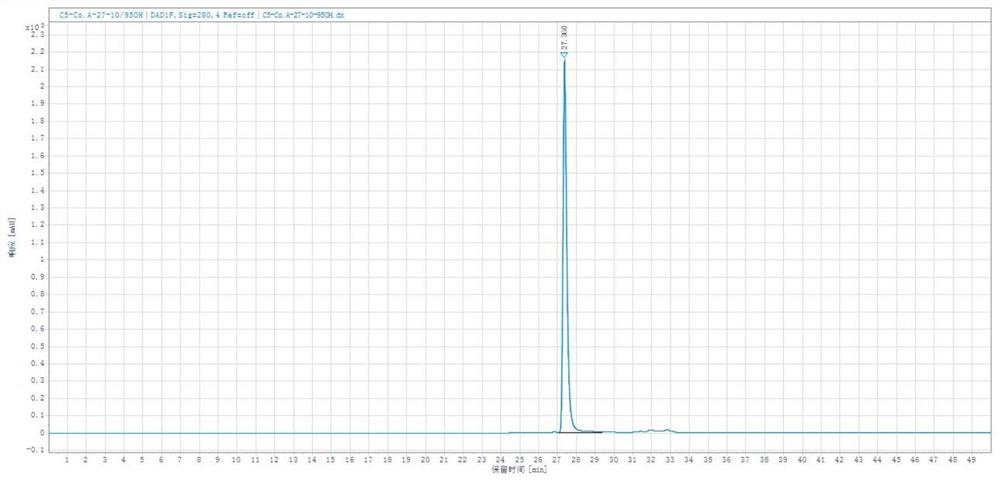

Image

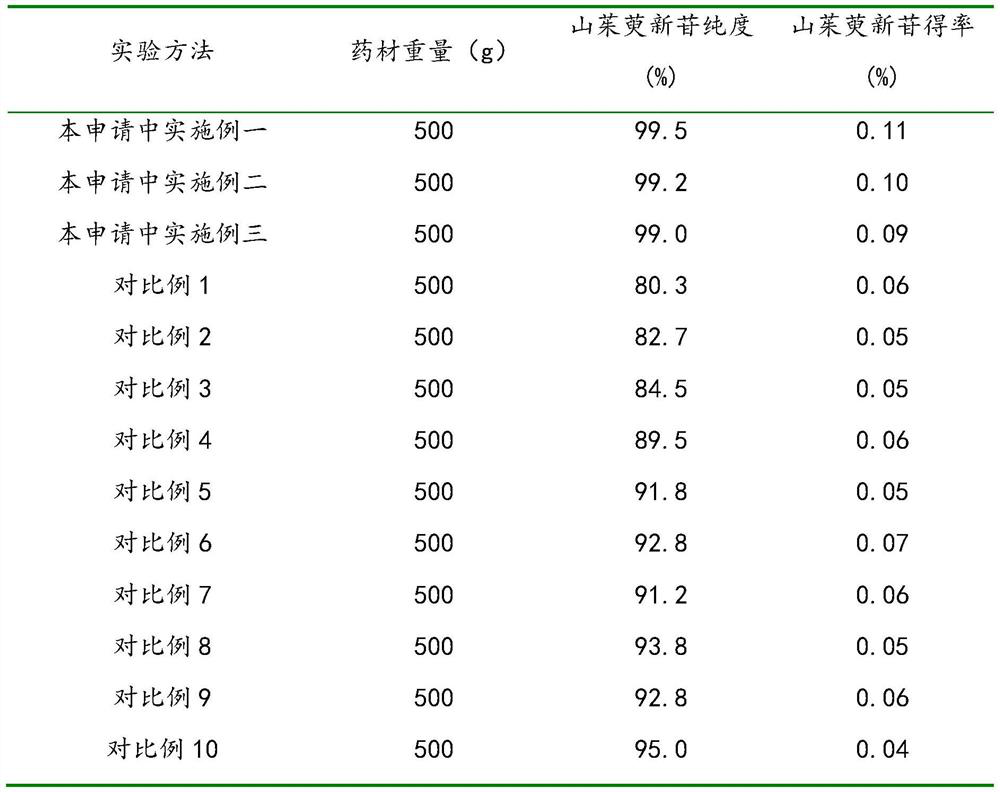

Examples

Embodiment 1

[0036] (1) Crushing the causing fruit into powder, add concentration of 50% ethanol to extract several times (for example, 2-4 times, 2-4h each time), combined extract, filtrate, concentrate to nano, concentrate liquid;

[0037] (2) After adding the above concentrated liquid, then extracts several times (e.g., 2-4 times) with ethyl acetate, combined with aqueous phase, concentrated under reduced pressure, and the water concentrate after extracting;

[0038] (3) The water concentrate after extraction is slowly absorbed in the D101 macroporous adsorption resin column, the wet mounting column (the amount ratio of the sample and the column resin is 1: 5), first elution of 6bV with 35% ethanol, discard After 55% ethanol eluting with 5BV, the eluate is collected into one-third or quarter of one-quarter, and the eluent containing halophysin is collected by thin layer chromatography or HPLC. The concentrate is concentrated under reduced pressure (the relative density is 1.15); in the conc...

Embodiment 2

[0043] (1) Crushing the causing fruit into powder, add concentration of 40% ethanol to reflux (for example, 2-4 times, 2-4h each time), combined extract, filtrate, concentrate concentration to nano, concentrate liquid;

[0044] (2) After adding the above concentrated liquid, then extracts several times (e.g., 2-4 times) with ethyl acetate, combined with aqueous phase, concentrated under reduced pressure, and the water concentrate after extracting;

[0045] (3) The water concentrate after extraction is slowly sampled in the AB-8 macroporous adsorption resin column, the wet mounting column (the amount of the sample and the amount of the column resin is 1: 5), first elution of 6bV with 35% ethanol, Abandon; eluate 55% ethanol, eluent is collected in one-third or quarter of one-quarter, with silica gel layer chromatography or HPLC, collect the elution of hawthorn Liquid, concentrate concentrate (1.10) under reduced pressure (density is 1.10); in the concentrate in 60-100 alcohol-solub...

Embodiment 3

[0048] (1) Crushing the fruits of the hawthorn into coarse powder, add 60% ethanol to extract several times (for example, 2-4 times, 3 hours each time), combined with extract, filtrate, concentrate to nano, concentrate;

[0049] (2) After adding the above concentrated liquid, then extracts several times (e.g., 2-4 times) with ethyl acetate, combined with aqueous phase, concentrated under reduced pressure, and the water concentrate after extracting;

[0050] (3) The water concentrate after extraction is slowly sampled in the HP-20 macroporous adsorption resin column, the wet mounting column (the amount ratio of the sample and the column resin is 1: 5), first elution of 6bV with 35% ethanol, Abandon; eluate 55% ethanol, eluent is collected in one-third or quarter of one-quarter, with silica gel layer chromatography or HPLC, collect the elution of hawthorn Liquid, concentrated concentrate (relative density of 1.13); in the concentrate in 60-100 alcohol-soluble polyamide resin columns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com