Biomass polyester P based on homovanillic acid as well as preparation and application thereof

A high vanillic acid and biomass technology, which is applied in identification devices, instruments, optical components, etc., can solve the problems of poor polyester tensile properties, poor transparency, dark color, etc. The effect of improving membrane performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

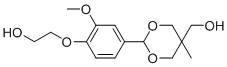

[0037] Synthesis of a diol monomer M1: at room temperature, N 2 Under protection, 9.00 g (0.04 mol) of 4-(5-(hydroxymethyl)-5-methyl-1,3-dioxane)-2-methoxy with CAS number 1089332-89-7 Phenol and 6.90g (0.08mol) of ethylene carbonate were put into the reaction vessel, 100ml of N,N-dimethylformamide (DMF) was added and stirred to dissolve, and 1.83g (0.01mol) of potassium carbonate was added as a catalyst, at 160 The reaction was stirred at °C for 3 hours, and cooled to room temperature after the reaction was completed. Then add 50.0ml (0.10mol / L) of sodium hydroxide solution to it under stirring, precipitate white insoluble matter, filter, wash the filter residue twice with 200mL distilled water, and then dry the filter residue in an oven at 50°C for 1~2h to obtain A diol monomer M1 is , and the yield was 86.00%.

Embodiment 2

[0039] Synthesis of a dibasic acid monomer M2: 1.82g (0.01mol) of homovanillic acid and 50ml of acetonitrile were placed in the reactor, and 2.31g (0.01mol) of 2,2'-dibromodiethyl ether was slowly added under stirring Add it into the reaction vessel, stir and react at 110°C for 5 hours, stop heating, then add 500ml of cold distilled water to the reaction mixture, precipitate insoluble matter, filter, wash the filter residue with distilled water 3 times, filter again, put the filter residue in an oven at 60°C dry in medium for 2~3h to obtain a dibasic acid monomer M2 that is , the yield is 85.00%.

Embodiment 3

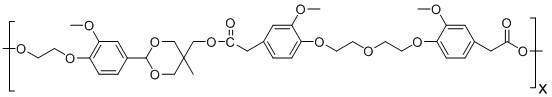

[0041] Replace the air in the reaction system with nitrogen, and under the protection of nitrogen, put 3.14g (0.01mol) of dibasic alcohol monomer M1 and 4.34g (0.01mol) of dibasic acid monomer M2 into the reaction vessel in turn, and Add 0.006g germanium dioxide, stir and react at 160°C for 5 hours, then control the vacuum degree of the reaction system at 80Pa, heat the reaction mixture to 210°C within 1h, continue to stir and react for 3.0 hours, cool the reaction mixture under nitrogen atmosphere, and then Add chloroform to the reaction mixture to dissolve, filter, add enough methanol to the filtrate until the precipitation no longer increases, filter, wash the obtained filter residue with cold methanol for 3 times, filter again, and then dry it in an oven at 75°C for 3 Hours, polyester P1 was obtained with a number average molecular weight of 54000 g / mol and a yield of 85.53%.

[0042] Preparation of highly transparent protective film for display panels: mix 100g of polyest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com