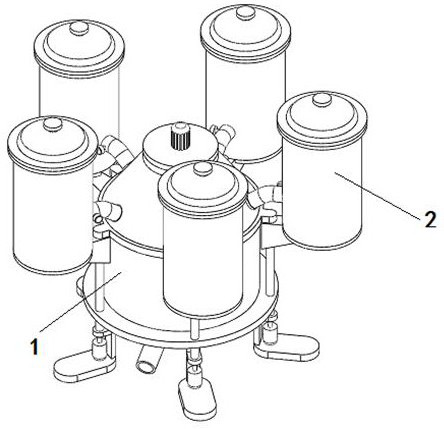

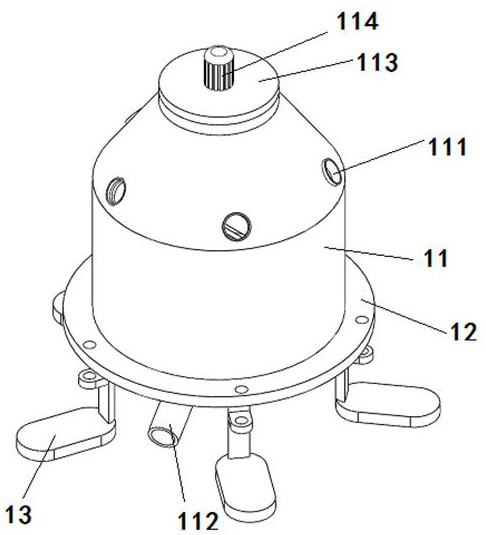

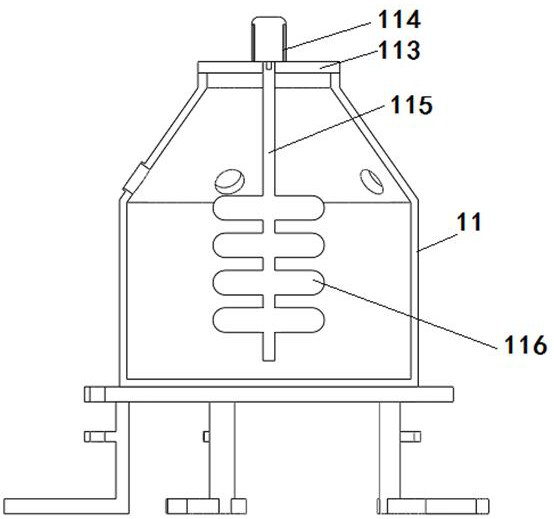

Composite microbial preparation for degrading kitchen garbage and preparation device

A technology of compound microorganisms and kitchen waste, applied in the field of self-service terminal equipment, can solve the problems of low fermentation activity, poor salt tolerance, and inability to effectively degrade oils and fats, and achieve the effects of fast growth, rapid decomposition and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The first step, the preparation of Pseudomonas aeruginosa seed liquid, diplococcus seed liquid:

[0032] Cultivate the slant test tubes of Pseudomonas aeruginosa and Diplococcus strains at 30°C for 72 hours in a constant temperature incubator, according to 1% peptone, 0.5% sodium chloride, 0.2% yeast powder, 0.25% dipotassium hydrogen phosphate, sucrose 0.5%, the mass ratio of 3% swill oil is taken by weighing, is dissolved in 1000ml distilled water, adjusts pH value to 7.5, obtains liquid culture medium A, inoculates Pseudomonas aeruginosa, diplococcus respectively in liquid culture medium A and shakes The bed was cultured at 30°C until the number of viable bacteria of Pseudomonas aeruginosa and diplococcus was greater than or equal to 10.0×10 8 CFU / mL, Pseudomonas aeruginosa seed liquid and diplococcus seed liquid were obtained respectively;

[0033] The second step, the preparation of Pseudomonas aeruginosa fermented yeast liquid and diplococcus fermented yeast liqu...

Embodiment 2

[0049] The first step, the preparation of Pseudomonas aeruginosa seed liquid, diplococcus seed liquid:

[0050] Cultivate the slant test tubes of Pseudomonas aeruginosa and Diplococcus strains at 30°C for 72 hours in a constant temperature incubator, according to 1% peptone, 0.5% sodium chloride, 0.2% yeast powder, 0.25% dipotassium hydrogen phosphate, sucrose 0.5%, the mass ratio of 3% swill oil is taken by weighing, is dissolved in 1000ml distilled water, adjusts pH value to 7.5, obtains liquid culture medium A, inoculates Pseudomonas aeruginosa, diplococcus respectively in liquid culture medium A and shakes The bed was cultured at 30°C until the number of viable bacteria of Pseudomonas aeruginosa and diplococcus was greater than or equal to 10.0×10 8 CFU / mL, Pseudomonas aeruginosa seed liquid and diplococcus seed liquid were obtained respectively;

[0051] The second step, the preparation of Pseudomonas aeruginosa fermented yeast liquid and diplococcus fermented yeast liqu...

Embodiment 3

[0067] The first step, the preparation of Pseudomonas aeruginosa seed liquid, diplococcus seed liquid:

[0068] Cultivate the slant test tubes of Pseudomonas aeruginosa and Diplococcus strains at 30°C for 72 hours in a constant temperature incubator, according to 1% peptone, 0.5% sodium chloride, 0.2% yeast powder, 0.25% dipotassium hydrogen phosphate, sucrose 0.5%, the mass ratio of 3% swill oil is taken by weighing, is dissolved in 1000ml distilled water, adjusts pH value to 7.5, obtains liquid culture medium A, inoculates Pseudomonas aeruginosa, diplococcus respectively in liquid culture medium A and shakes The bed was cultured at 30°C until the number of viable bacteria of Pseudomonas aeruginosa and diplococcus was greater than or equal to 10.0×10 8 CFU / mL, Pseudomonas aeruginosa seed liquid and diplococcus seed liquid were obtained respectively;

[0069] The second step, the preparation of Pseudomonas aeruginosa fermented yeast liquid and diplococcus fermented yeast liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com