Method for preparing single-substance material by utilizing reduction of monatomic carbon

A technology of atomic carbon and single substance, applied in the field of materials, can solve the problems of high cost, high energy consumption, poor crystallinity, etc., and achieve the effect of high cost, high energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 30g of nickel oxide NiO was ball milled into powder.

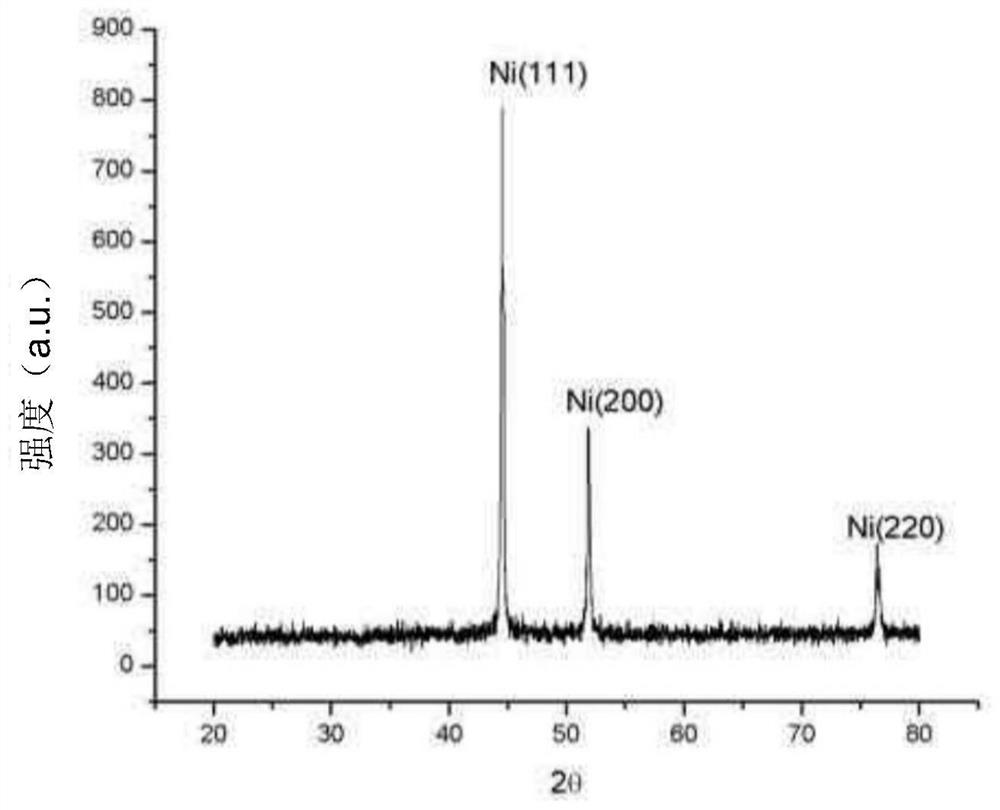

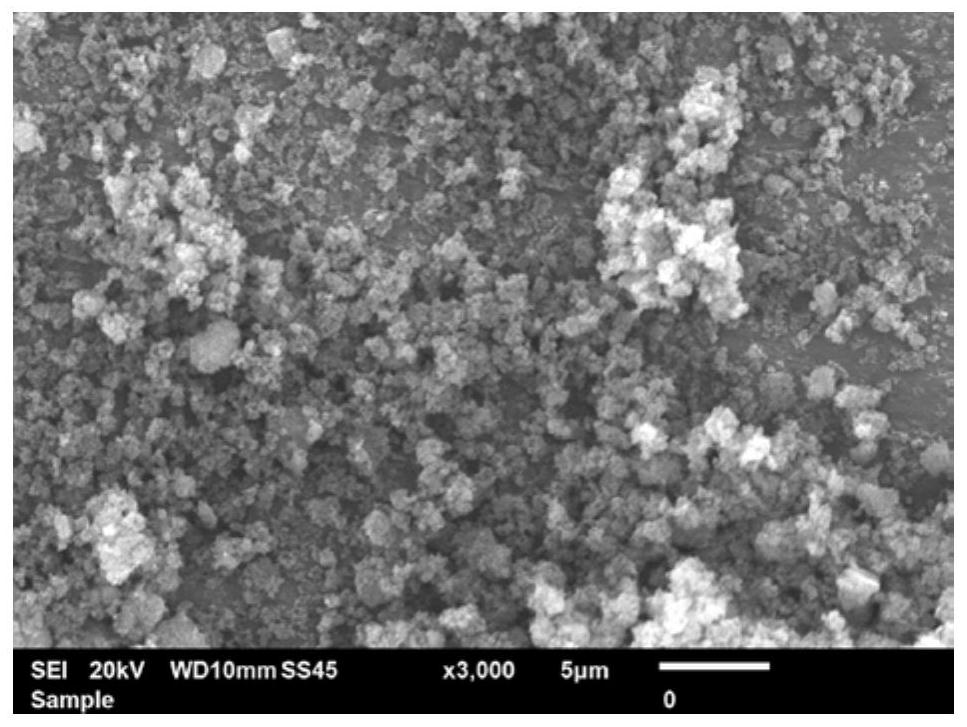

[0029] Place a flat-bottomed tank container in the vacuum chamber, put 500gMgCl in the flat-bottomed tank container 2 Heat to above 900°C to form a molten salt; add 30g NiO powder (as elemental Ni precursor compound) gradually from the surface of the molten salt, and use a stirring device to uniformly disperse the powder in the melt while the NiO powder is settling; at the same time, the organic carbon source The acetylene gas is continuously fed into the molten salt, and the high temperature makes the acetylene cracked into atomic carbon and hydrogen-containing gas, the gas is released, the atomic carbon dissolves and diffuses in the molten salt, and the atomic carbon reduces the NiO dispersed in the melt to form Ni; the nickel powder sinks to At the bottom of the high-temperature melt, cool to room temperature, first dissolve the cooled crystals of the melt with water and wash away MgCl 2 , filtered to obtain a m...

Embodiment 2

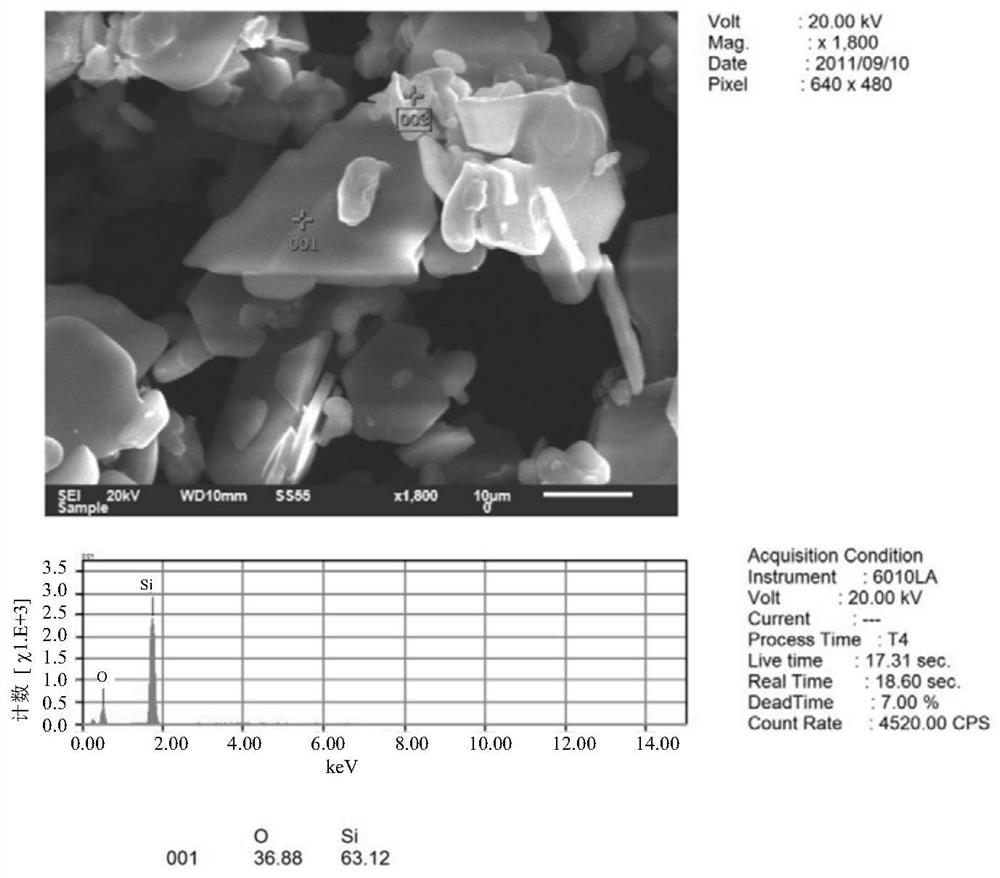

[0032] Place a square flat-bottomed container in the vacuum chamber, which contains a Bi / In alloy (Bi:In=21.5:78.5, in terms of atomic fraction; at this time, the melting point of the alloy is only 72°C), and the alloy is heated to 700°C to form a melt ; using a vertical transfer screw to transfer ZrF 4 (melting point 640°C, as elemental Zr precursor compound) powder is transported to the container and melted at the same time; pressurized acetylene is passed into the alloy melt through a circular tube, at this high temperature, acetylene is cracked into atomic carbon, atomic carbon is dissolved and reduced to melt ZrF in body 4 And generate Zr simple substance. Since the density of Bi / In alloy is close to 10g / cm 3 , Zr finally floated to the surface of the high-temperature melt; the floating product was removed from the melt surface with a horizontal scraper and collected; a small amount of Bi / In alloy stained on the obtained solid crystal was washed Ultrasonic washing is a...

Embodiment 3

[0034] 500g of anhydrous borax (Na 2 B 4 o 5 (OH) 4 ), heated to 950°C and melted into glass. 100g of organic carbon source bisphenol A is transported into the container with a vertical conveying screw while stirring to make it evenly dispersed in the melt; because the melt contains acidic oxide B 2 o 3 (as elemental B precursor compound), bisphenol A is completely cleaved, cracked into atomic carbon, atomic carbon dissolves and reduces B in the melt 2 o 3 Generate elemental boron B. After cooling to room temperature, the elemental boron B and the recrystallized anhydrous borax are repeatedly washed and filtered with water, and pure elemental boron B is finally obtained by utilizing the easy solubility of anhydrous borax in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com